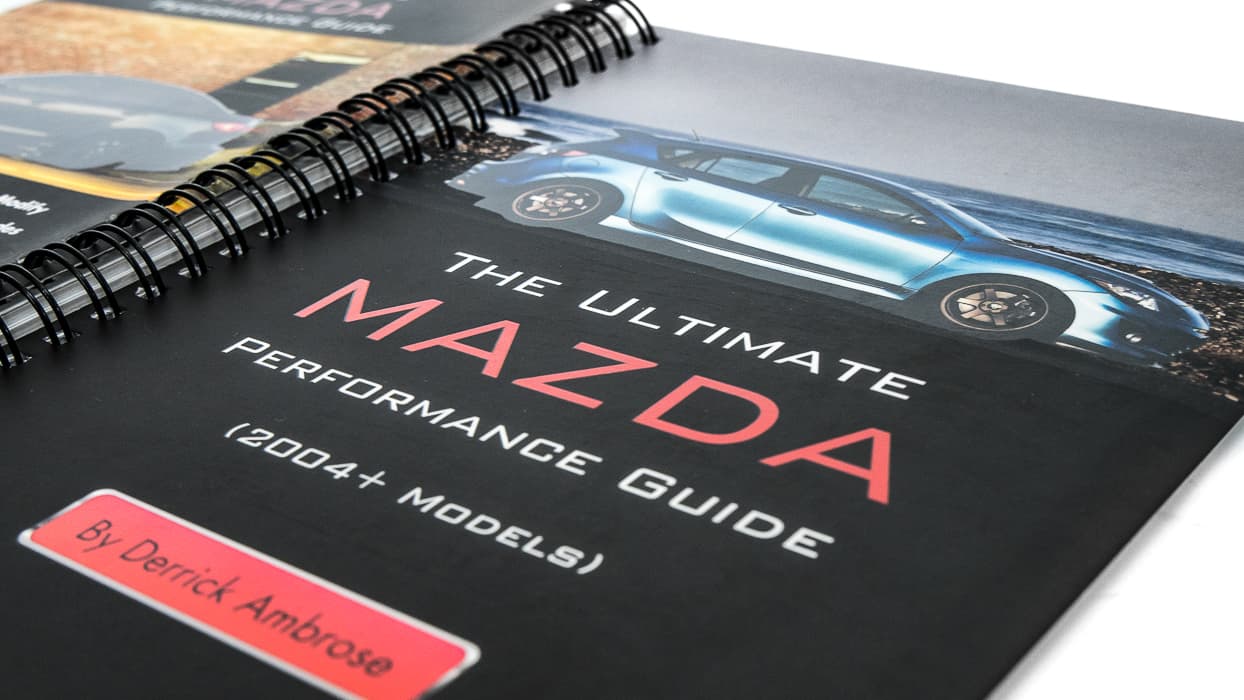

A few years ago, CorkSport’s resident racecar driver – Derrick Ambrose – released a book titled The Ultimate Mazda Performance Guide.

The wildly popular book provides beginner and intermediate Mazda/Mazdaspeed owners a solid guide that outlines how, why and when to modify their ride. Now that the platform is a little older, these second-hand models are more attainable for first-time car buyers and Mazdaspeed Owners specifically are hungry to transform their ride into a +400 WHP BEAST!

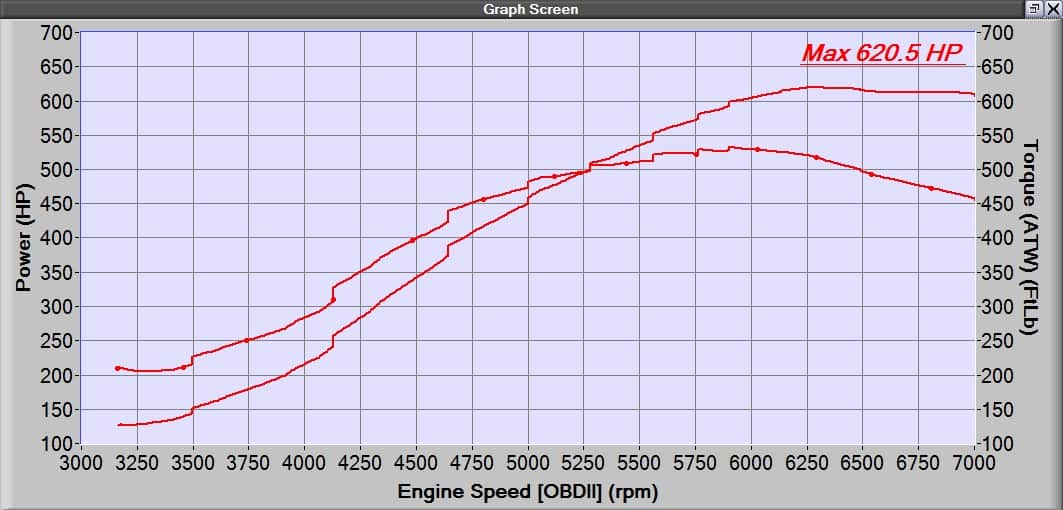

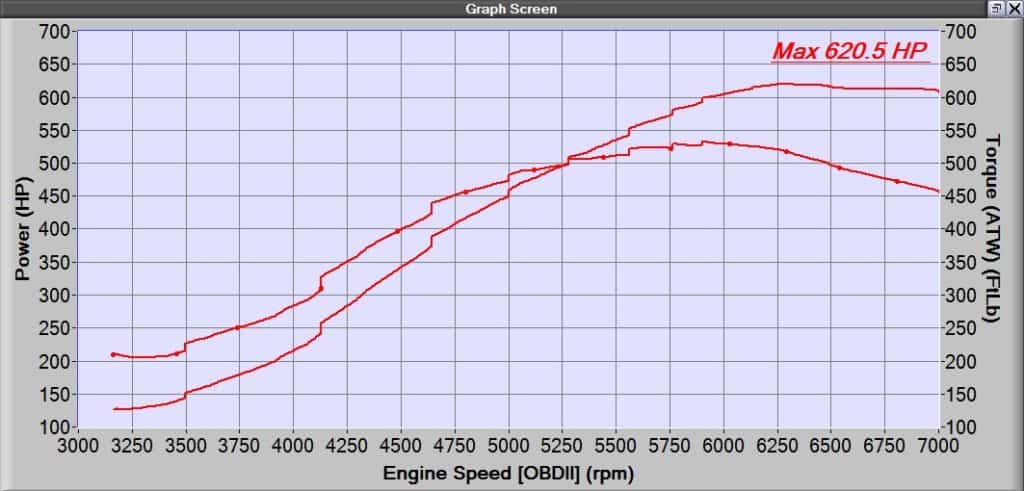

With so many new enthusiasts joining the Mazdaspeed platform, we have been flooded with inquisitive calls and see an increasing number of new owners post up questions about turbos, High Pressure Fuel Pump Internals, axle back vs cat back vs turbo back exhausts, and what can I do to make 400 WHP or even 600 WHP?

Many of these new Mazda enthusiasts are joining CorkSport’s premier 7th Gear Membership to take advantage of the free swag package, free shipping in the lower 48 states and immense benefits from the troll free and exclusive 7th Gear Facebook Group – Where beginners can ask questions without getting clobbered!

So, whether you’re just starting out with a new to you Mazdaspeed3 or Mazdaspeed6, or you’ve hit the ground running with a new MX-5, Mazda3 or Mazda6 (turbo diesel!?). Our Mazda performance Guide will help answer some basic questions as well as set you on your path to get the most out of your ride.

Previous Interview with Derrick:

CorkSport: What made you decide to write a book about Mazda Performance and why?

Derrick: I really just wanted to give some of the new Mazda enthusiasts some of the knowledge that I have gained about Mazda’s from my involvement with them since the mid 90’s. Many people are just now buying their first Mazdaspeed and don’t really know where to begin. I wanted to help ease them into what they really need to know. It can be quite scary for some to jump into modifying or go into the forums or Facebook groups and not know anything.

CorkSport: We know all about the forums and responses to Newbs on Facebook haha.

Derrick: Exactly, the purpose of the book was to help give people a path and empower them with information that may take a lot of years or a lot of searching to find. I didn’t want it to just be about selling CorkSport parts, we actually mention, and feature, many non-CorkSport parts in the book. That being said, I’m very proud of CorkSport and what we have done to help the Mazda community.

CorkSport: So who is this book really for?

Derrick: I wrote this guide for the beginner to the intermediate Mazda enthusiast that really wants to learn more and really get the most bang for their buck. I wanted to answer some of the most common questions I’ve seen on the forums and in person about aftermarket performance and where to start. If you have changed your turbo or are cross-weighing your coil-overs, you are probably past this book in terms of technical ability. I did, however, include many sources for additional information, contacts and even a brief history of Mazda itself; which is a topic I may even write another book on for the true Mazda fanatic.

CorkSport: I see, what do you think was the most challenging thing about creating a book?

Derrick: Everything, (laughs). When you have no idea what you’re doing as an ‘author’, it takes a LOT more time than you could ever imagine. I was lucky to have a lot of help from some truly amazing people and am very grateful to all of them. Writing a book is a much bigger endeavor than I would have every thought, but having an actual piece of history afterward is truly a special moment. Having that glossy cover in my hands, seeing the ISBN on the back and knowing that I will be in the Library of Congress forever is just an amazing feeling. It’s weird how just making a book can make you feel patriotic, but it really did.