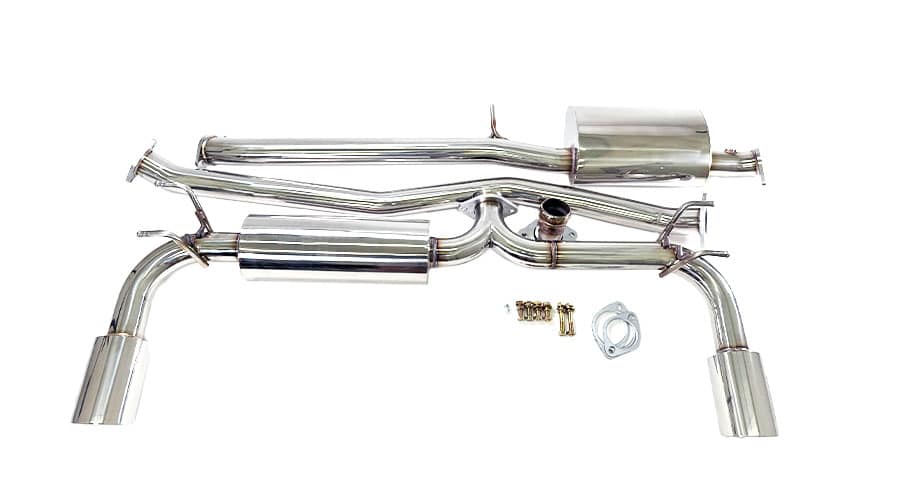

Introducing the new CorkSport Cat Back Exhaust for the 2023+ CX50. We are excited to bring another awesome performance product to the CX50 community…this time we really want to make some noise about it! Stainless steel construction, 4-inch tips, and an exhaust tone you’ll love every day. This defines the new CorkSport exhaust.

The Exhaust to Match the CX-50

The CX50 is already a fantastic-looking SUV (heck, we have two of them in the lot!) with great power and capabilities on and off-road. Much like our development of the Mazda 3 & CX30 exhaust systems, we pursued a design that would add to the overall driving experience of the CX50, but it’s so quiet. Like a dog without a bark! We sought to change that with the CorkSport Performance Exhaust.

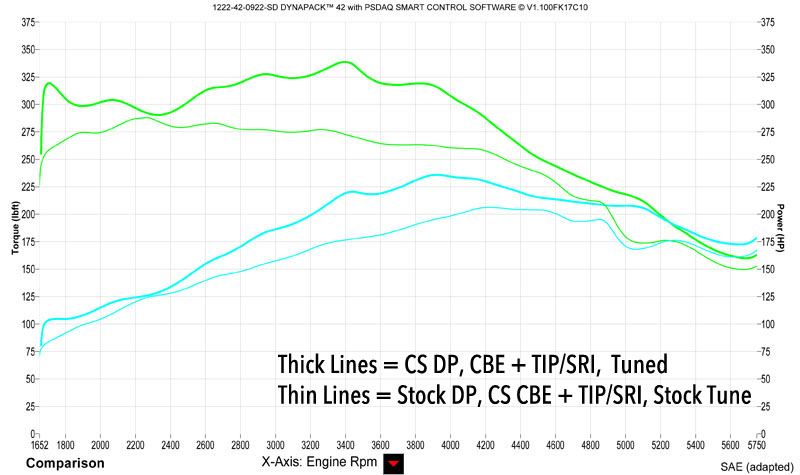

The CorkSport asymmetric design may not be conventional, but it has a purpose. The long high-flow resonator on the driver side controls the drone and rasp that would otherwise entire the passenger compartment, while the shorter passenger side utilizes 63.5mm mandrel bent piping to allow an exciting growl out of the exhaust. Combined, we found the balance of noise output and drone control, creating a fun and comfortable performance exhaust for your daily driven CX-50.

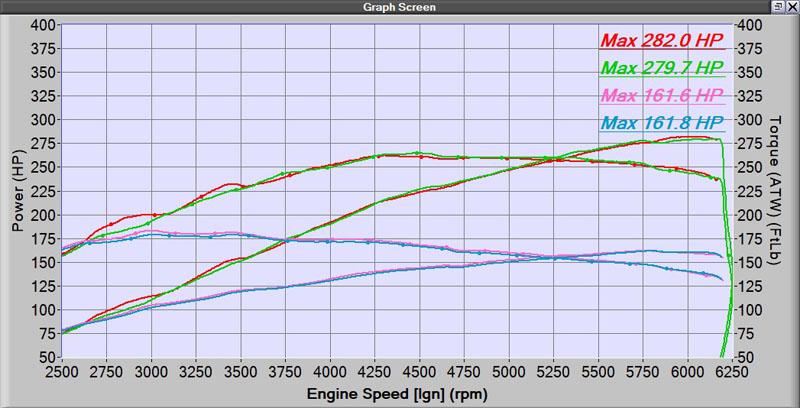

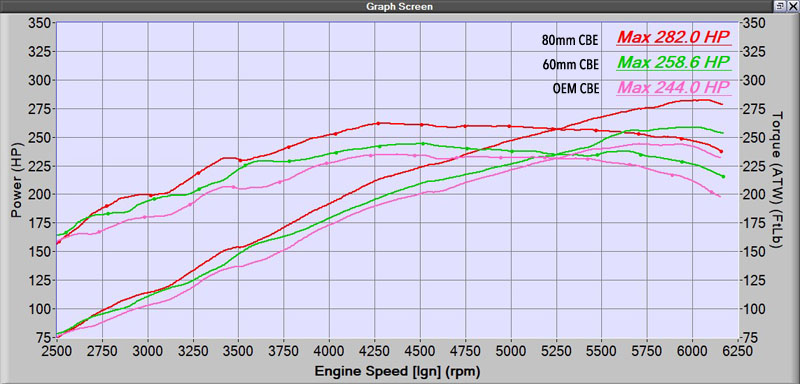

Exhaust Options

Our current release is for the entire Cat-Back Exhaust system, which will provide a more pronounced exhaust note. For those looking for a less aggressive exhaust note, we offer the CX-50 Axle-Back exhaust system that still provides an improved look and sound. Add the Axle back to your OEM midpipe and you’re ready to go!

Designed to Fit

Like all CorkSport Exhaust Systems, the performance CX50 exhaust is designed to fit like OEM and maintain great ground clearance & departure angles for those off-road adventures. The 4-inch dual wall slant cut tips fit tightly in the OEM bumper cutouts and follow the great body lines of the CX-50. Designed for all AWD models of the CX-50 Turbo and non-Turbo.

In our R&D testing, we found that Mazda allowed some manufacturing inconsistencies in its OEM exhaust components. As a result, we redesigned our exhaust with an adjustable flange that will compensate for these disparities.

What does that mean exactly? We’ve incorporated a new “ball & socket” connection that allows for maximum adjustment to ensure the perfect fit.

Quality Design

Construction of the CorkSport exhaust systems uses 304 stainless steel mandrel bent piping and TIG welded joints that are strong and beautiful. All the necessary hardware is included for a quick and easy installation with basic hand tools. Supporting all that are color step-by-step instructions and the support of the CorkSport team by phone, email, and message.

Thanks for checking out the new CorkSport Cat Back Exhaust for the 2023+ Mazda CX-50!

Connect with us

You may also like

- The New Look For Your Mazda CX-50 with Hood Mount Light Brackets!

- It’s Finally Here! The Performance Turbo Inlet Pipe for the Mazda SkyActiv-G 2.5L Turbo

- Improve Your Braking with the All New Big Brake Kit for the Mazda CX-50