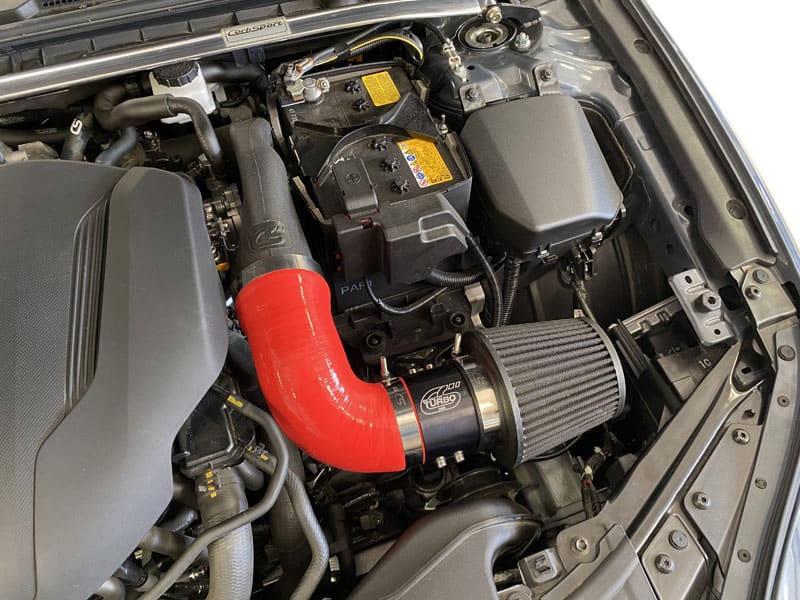

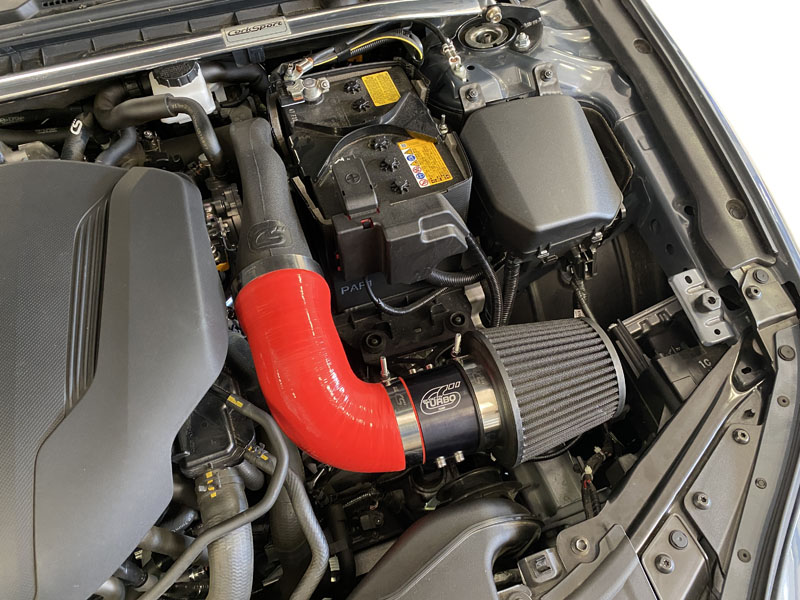

The best and most complete intake system for your Turbo Mazda is finally available! Introducing the last piece of the puzzle, the CorkSport Performance Turbo Inlet Pipe. Combine the turbo inlet pipe with the CorkSport Short Ram Intake and Heatshield to create the complete intake system for the SkyActiv-G 2.5T engine found in nearly every model Mazda currently produced.

Why does an upgraded turbo inlet pipe matter?

Power comes from efficiently flowing air in and out of the engine. When there is a restriction in the flow path, this causes a power and efficiency loss. Our goal was to design a new performance turbo inlet pipe that removes the restrictions of the OEM design, fits like OEM, and integrates perfectly with the already existing CorkSport Short Ram Intake and Heatshield.

Here you can truly see the difference in size! While the shape of the CorkSport Turbo Inlet Pipe is…unusual…it’s for good reason. We invite you to check out the design blog for more in-depth details.

In a nutshell, we investigated the typical aftermarket design path of a metal pipe, but a 2.5 inch metal pipe was not good enough. We thought outside of the box to truly design the best turbo inlet pipe option for the community. We moved up to a 3 inch inner diameter system to maintain a continuous 3 inch inner area matching the MAF housing.

It’s the final piece in the CorkSport 4th GEN Turbo Intake System making it the best and most complete intake system on the market!

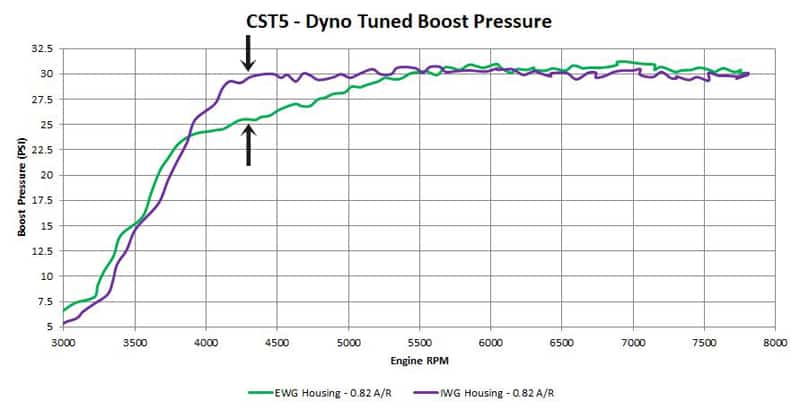

Turbo Inlet Providing Power Gains

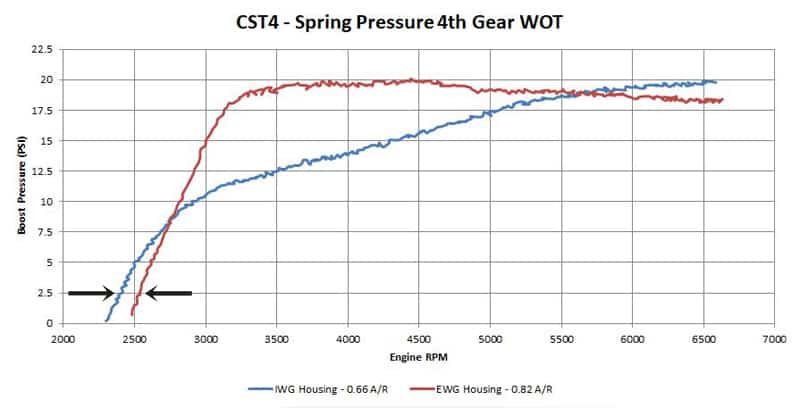

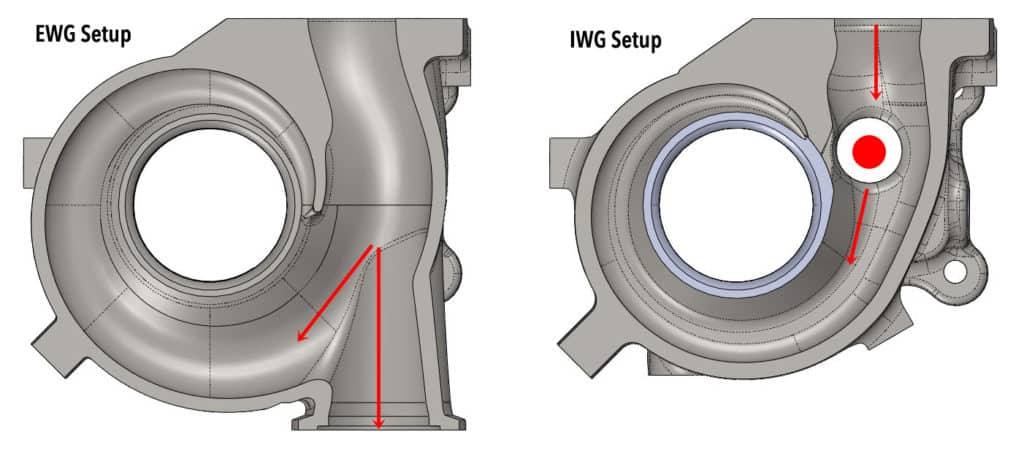

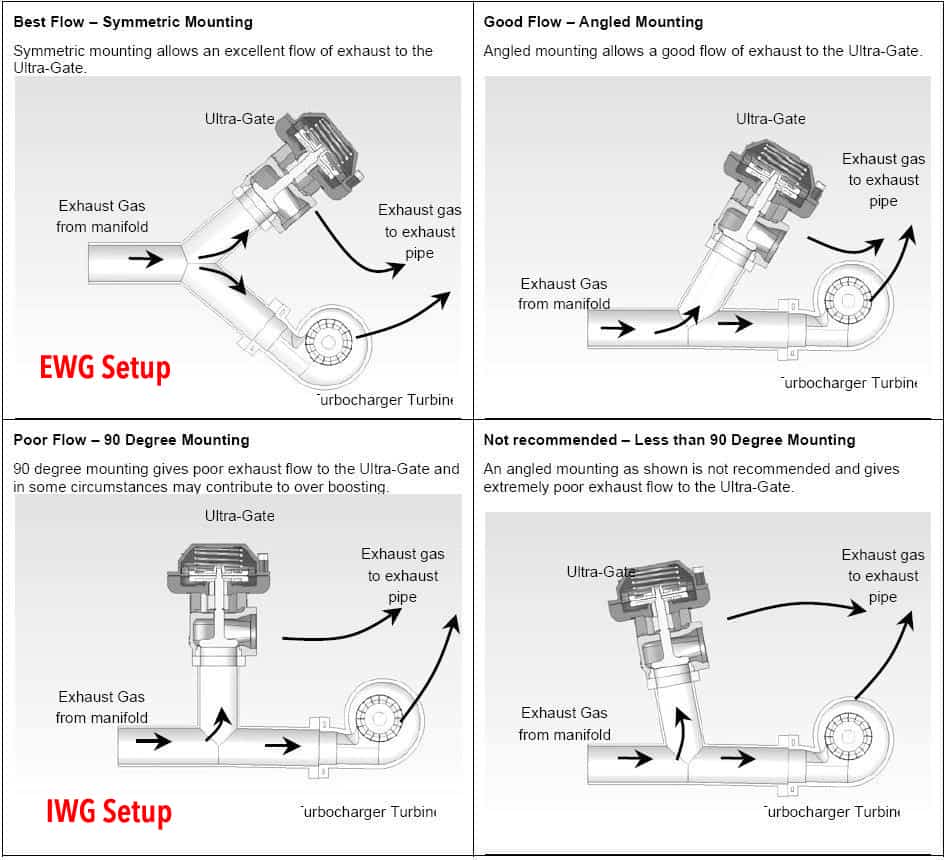

So does it make power? Short answer. YES IT DOES! While tuning for the 4th GEN Mazda platform is still primitive and restrictive, we are able to see faster spooling and higher flow before the ECU hits the load limits. This tells us we are making more power with the addition of the turbo inlet pipe to the existing CorkSport short ram intake system. It also tells us there is more potential in the system once tuning develops further. We can promise, as tuning does develop, we too will further test and validate the benefits of the turbo inlet pipe system.

Power gains are great, but another key addition to the driving experience is unleashing the induction and turbocharger noise trapped by the factory air intake system. The CorkSport SRI and TIP free up a surprising amount of turbo noise when driving around and provides more induction sound under hard acceleration. The extra level of turbocharger noise is enjoyable when you want, but doesn’t get in the way when you don’t.

The Turbo Inlet Pipe Made Is Better & Fits Like OEM

Let’s talk about how its made; the material and manufacturing method used is another advantage over the OEM counterpart. The CorkSport TIP is Roto-Molded out of a high temp nylon to offer good strength and flow while retaining an OEM-like appearance. The CorkSport TIP also utilizes two silicone couplers which are reinforced so they don’t deform under vacuum high load. The silicone coupler that connects the SRI to the TIP gives a nice smooth transition between the two when compared to the OEM coupler, which has ribs that introduce unwanted turbulent air into the TIP.

The outlet silicone that leads to the turbo features a barbed fitting to retain the valve cover breather and we also provide a silicone breather hose to connect the two together. This barbed fitting can also be used for an oil catch can if you want to add one in the future.

The last component that is included with the CorkSport TIP is the mounting bracket. The mounting bracket is made out of 304 stainless steel and was designed to work with both the air-to-air intercooler system found on the Mazda 6, CX-9, and CX-5 and the air-to-water intercooler system found on the Mazda 3, CX-30, and CX-50. From the factory they have different mounting locations for the TIP so we decided to offer a single mounting bracket that will work with which ever model you have.

As with most CorkSport performance products, this Turbo Inlet Pipe kit includes all the necessary installation hardware and color step-by-step installation instructions to ensure you have a quick and straightforward install.

The addition of the CS Turbo Inlet Pipe on your Turbo Mazda is a fantastic mod to further build upon your current CorkSport SRI. And Heatshield. At this time, no competitor intake systems have been test fit with the CorkSport Turbo Inlet Pipe.

Check it out below and be sure to contact us with any questions you may have, we will be happy to help!

The 4th GEN Turbo Inlet Pipe

The final component for the most complete intake system for your 4th Gen Turbo Mazda is finally available!

The 4th GEN Turbo Inlet Pipe

The final component for the most complete intake system for your 4th Gen Turbo Mazda is finally available!

Connect with us

You may also like:

- 4th GEN Mazda 3 SRI

- Performance Parts for the 4th Gen Mazda 3

- Coming Soon: The New Turbo Inlet Pipe – Mazda SkyActiv-G 2.5L