We (CorkSport) showed off our work-in-progress TC America TC Class Mazda 3 race car at the CorkSport Mazda Showdown event on August 5th. If you are asking yourself why this is a big deal and why I am reading a blog post about it, here’s the explanation.

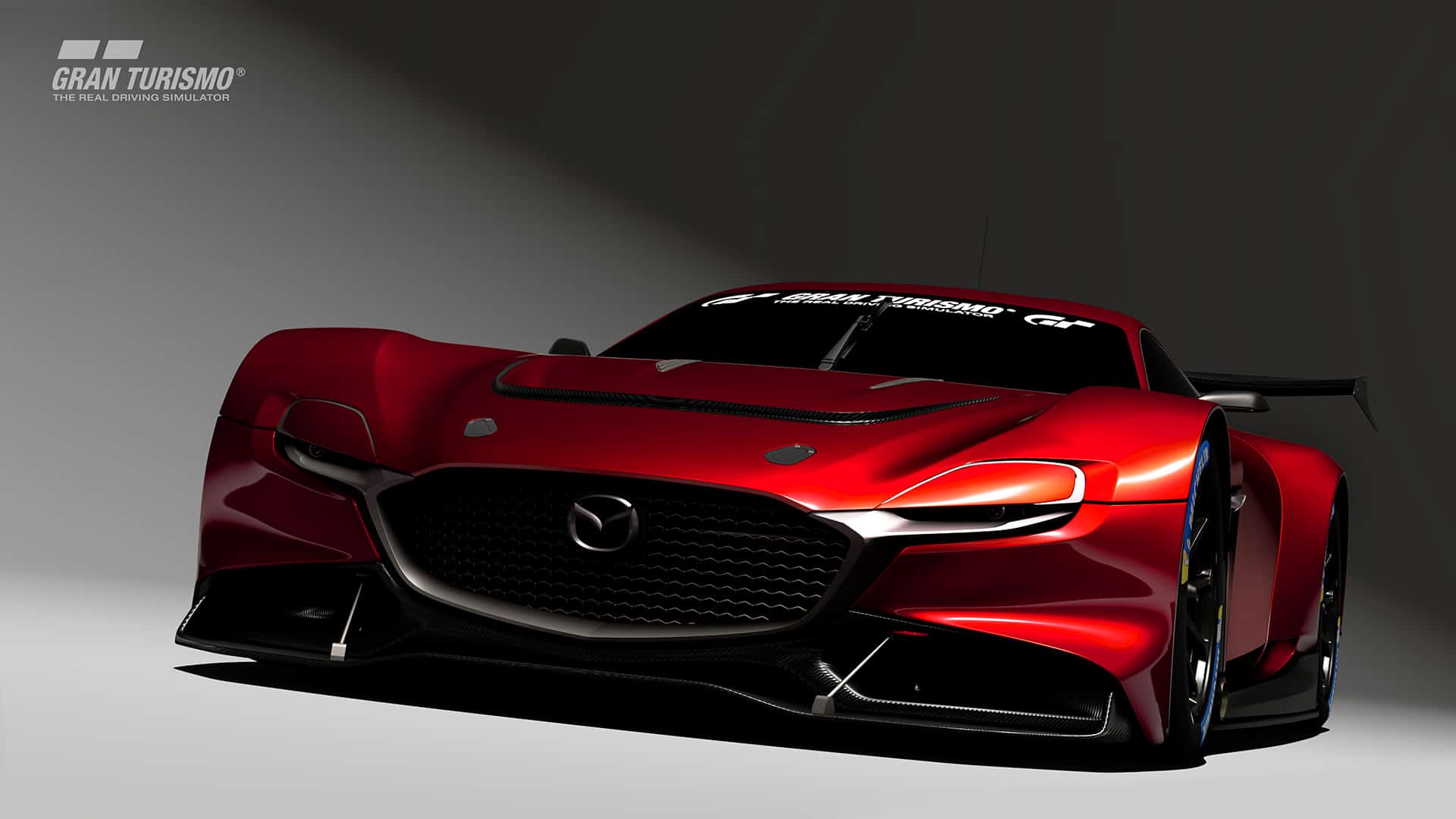

On October 1st, 2019, Mazda announced they would join the TCR ranks with the car attending the 2020 season opener at Daytona with IMSA. The bodywork was excellent; it captured the body lines and presented an absolute WOW factor!

Unfortunately, the car was a no-show at the first round or any round scheduled in 2020. On August 15th, Emily Taylor from Mazda announced they had canceled the TCR program, citing the coronavirus as the explanation.

What About The Body Kit?

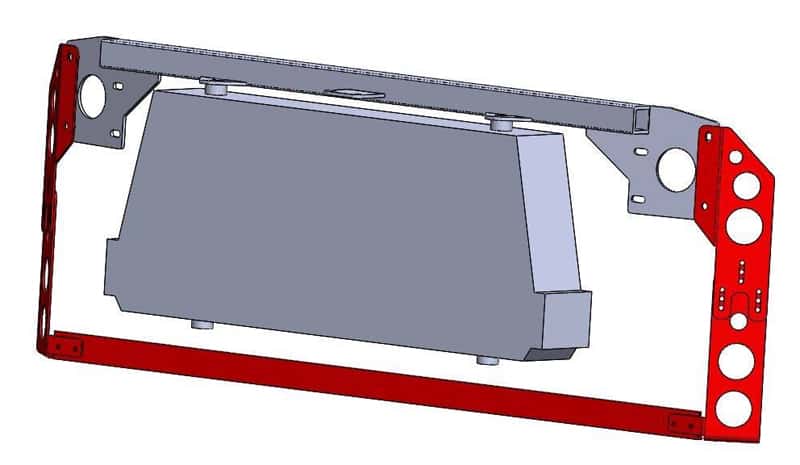

So what happened to everything from Mazda’s race program, and why is the bodywork a big deal? There were two sets of original molds made for the bodywork. The 1st set of molds went to the constructor Long Road Racing, and the second set sat at Mazda’s design center in Irvine, California.

The molds in Irvine were the first set made off of TCR “Show Car” bodywork and were not production-ready. The “Show Car” Mazda used for their 2019 announcement and future marketing campaigns wasn’t an actual race car. It was a production car with the bodywork on it, but the engine & drivetrain was stock.

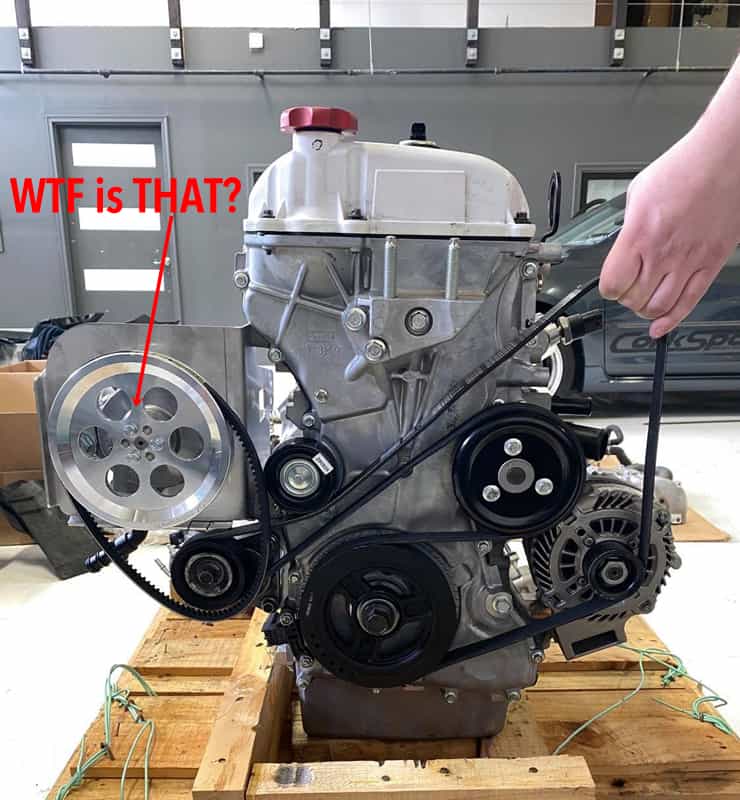

CorkSport has been racing a 3rd generation Mazda 3 in the TC class for several years as the development tool for the Skyactiv Turbo kit we offer.

When running in a professional series, the series works with manufacturers and wants the newest models competing on the track to keep the series fresh and relevant for marketing for both the auto manufacturer and the race series. The last 3rd Gen Mazda rolled off the production line in early 2018, making our race car over a year old when the TCR program was announced and over two years old when the program was canceled.

We needed to race the 4th Gen Mazda 3s to keep competing in TC America,

The Journey For the Mazda 3 TCR Kit

This may seem like an exaggeration, but I spent over 200 hours on the phone, in meetings, writing emails, and talking with employees, ex-employees, and contractors that Mazda used to chase down where the bodywork went, who was ultimately in charge of it, and to see if we could get our hands on it.

Once I knew the molds still existed, additional meetings, phone calls, and emails were required before signing an, “OK, we will consider it. Your plan and history jive with a company (CorkSport) that can use the parts and provides a benefit to Mazda.” type of agreement. During this time, I learned the first set of molds had been destroyed, making the motorsports molds the only set left.

In October 2022, snagging the TCR bodywork molds became a strong possibility. I was headed to Texas to drop off some racing equipment to a friend. I decided to leave my truck and trailer in Texas since the bodywork molds were now located on the East Coast. If Mazda agreed we could pick up the molds in the next few months, the truck and trailer would already be halfway there.

December 12th, 2022, Mazda gave me the green light to gain access to the molds after several more phone calls, ZOOM meetings, and agreements were made. I flew back to Texas and headed to Multimatic in Mooresville, NC, to complete this epic quest. After one very long drive, including a massive ice storm, and making it home on Christmas Eve, Mazda’s TCR molds were at CorkSport.

Since then we have been planning and slowly building the new TC Car – We cannot thank Mazda Motorsports enough for choosing to partner with us as we continue to shape our racing program!

might look like in the future – rear window will eventually be plexiglass.

Are These The Real Thing?

A common question that will get asked is, “I have seen the Mazda 3 TCR kit overseas, how is what you have the real thing?” Well, my friends, Technology and replication are a wonderful thing.

I asked the same question about the hill climb machine that TCP put together for Mike. If you compare the kits, you can see there are some differences in the kits with the aero, brake cooling, grill area, and more.

It was unofficially stated there were body scans done of the show car with Mazda Japan and those are the results. I cannot speak about the Thailand car but a handheld scanner and some import auto salon are my best guess.

Look forward to more updates on our build over the next several months, This is going to be fun!

-Derrick

Connect with us

You may also like

- Ride The Unicorn with the CorkSport 3rd Gen Mazda 3 & Mazda 6 Turbo Kit

- Turbo Kit in Development for 2014+ Mazda 3 & 2013+ Mazda 6

- CorkSport Races at Road America

- 25 hours of Thunderhill