Since the release of our Oil Catch Can we have had a lot of questions about how our set-up functions. Most understand the basics of what the OCC does, but want to know more about how the OCC does it.

The Basics

For the last 20 or so years, all cars have had some sort of PCV system installed to re-burn unwanted vapors from your crankcase instead of venting them to the outside world. This system is based on a vacuum. When the engine is running, the pistons are happily moving up and down. There is a small amount of compression that is lost into the crankcase passing by the rings. This excess air will cause pressure in the crankcase to slow down the pistons from going up and down and build up oil vapors that create frothing of the oil. There are also small amounts of condensation that get trapped in the crankcase and you don’t have to be a rocket scientist to know water and oil don’t mix.

An oil catch can is designed to “catch” unwanted vapors that are in your crankcase and PCV system and prevent these contaminants from entering your motor. With no catch can install, you have the potential to get build-up in the intake manifold causing dirty valves and poor compression.

How the Mazdaspeed 3 PCV System Works

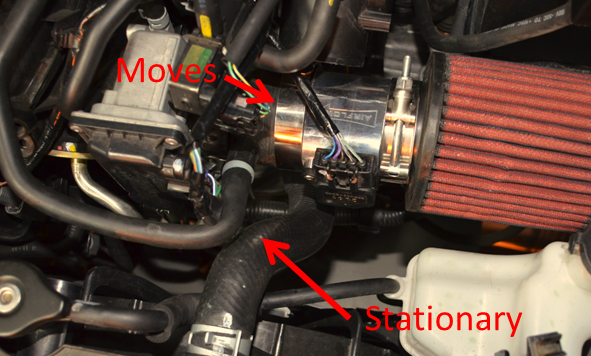

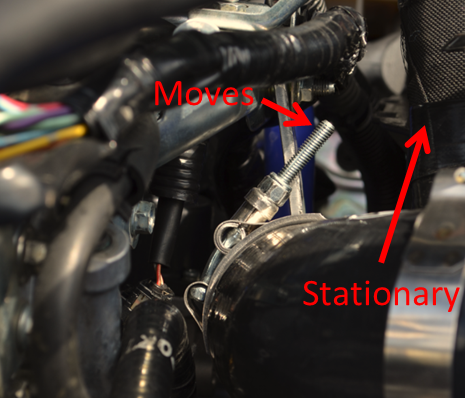

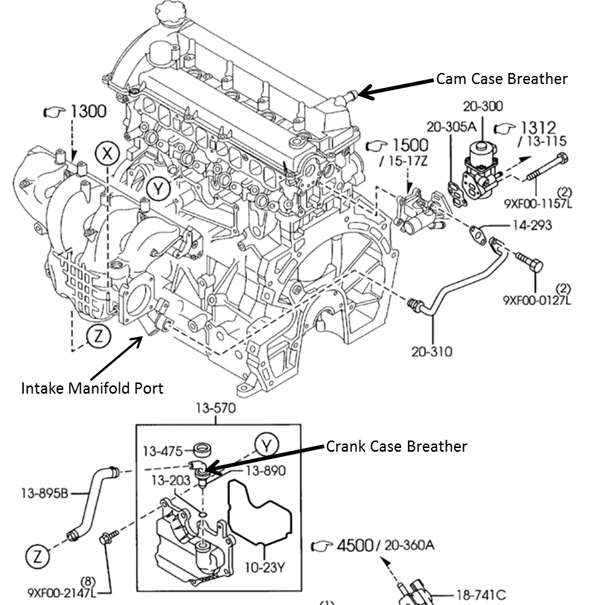

A Mazdaspeed 3 has two PCV lines. One goes from the cam cover to the intake and one goes from the crankcase to the intake manifold. Why the two locations you ask? Well, they go to the closest vacuum source, but in a turbo car, you will not have a vacuum when you are in boost so a check valve closes and stops the crankcase from being pressurized and boost being lost.

Improving the Design of the CorkSport OCC

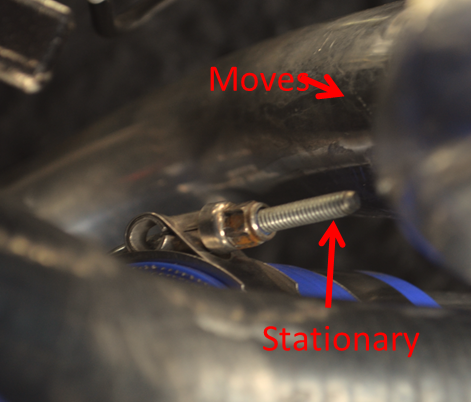

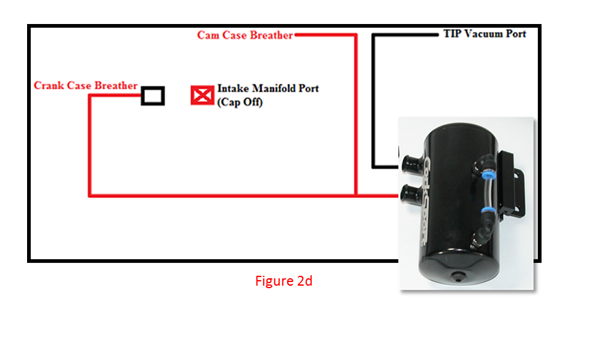

Most Oil Catch Cans include a PCV valve in the set-up for turbo vehicles, as ours did until just recently. So why does CorkSport no longer have a Check Valve on our Oil Catch Can setup? This is a great question.

We noticed that by adding the PCV check valve to the oil catch can, the OCC worked less effectively because when the check valve closes (the car is under boost) the catch can is no longer able to do the same job of “catching” the vapors. When your car is under boost is the time the catch can is working the hardest to prevent those contaminants from entering your engine. Instead, it is just sitting there waiting for the PCV valve to open back up.

We decided to cap the intake manifold and pull the vacuum through the intake so both cam and crankcase vapors are trapped in the OCC leaving your motor the cleanest it can be. Now, the CorkSport Catch Can will be working to eliminate those vapors all of the time without the restriction of a PCV valve to prevent it from being able to remove contaminants while your car is under boost.

So why not cap the intake and the intake manifold and have it vent to atmosphere?

There are several reasons this is a bad idea and being friendly to mother nature is only one of them. Yes, you might sleep at night better knowing you are not hurting the environment but this is not the only reason to plumb the catch can back into the intake.

1. The intake vacuum helps draw vapors out of the motor by creating a low-pressure system to force the vapors out. Without the vacuum, the vapors can only be forced out by the pressure in the crankcase. This is unreliable and inefficient. Think of how much easier it is to get air into the motor under pressure (ie turbo). It only makes sense that the opposite would be true about getting it out and it would be much easier to achieve under vacuum.

2. Metered air passes through the MAF sensor before entering the engine, then a small amount is passed by the rings and enters back into the intake or intake manifold. If you do not route the PCV back into the intake manifold then that calculated air is “poof” let out into space causing your fuel trims to be off.

If you think you can tune around this, you are correct. As the rings degrade, you will have a small amount of additional air passing by the rings. Time to re-tune. The rings degrade some more, then time to re-tune again. I think you get the picture. Eventually, you forget to keep up on this and your fueling is off enough to cause a check engine light or worse. Zoom-Zoom-Boom!

This is the nature of a MAF-sensored car. There is a good reason that Mazda has everything hooked back up to the intake. Your car will be happier, in the long run, doing this.