The development and evolution of the CorkSport Performance CST5 and CST6 turbochargers are uniquely intertwined. We’ll be honest, we started with the goal of a single larger turbo than the CST4 in mind, but as development progressed, we were not getting the exact results we wanted. We wanted fast spool & transient response, huge power, and to retain the internal wastegate system. Something had to give…we realized that we were asking too much from a single turbocharger, thus we redefined what we wanted and realized that two separate and focused turbochargers for the Mazdaspeed platform were the ideal choice.

Today we will focus on the design around the glorious CST5 Mazdaspeed Turbo, specifically the theory and design around the wheel selection for the CST5 and why it works.

CST5 Wheel Design

The compressor wheel utilized on the CST5 is the well-known and trusted GEN1 GTX71. Compact and efficient, this compressor is rated for a 56 lbs/min flow rate with a relatively high-pressure ratio threshold. Paired with a 4-inch anti-surge compressor housing and we have a very versatile and responsive compressor setup.

Now here is where the design begins to deviate from the standard path. The turbine wheel is an MHI TF06 design that is designed for high-performance applications. The TF06 turbine wheel is the key to the performance of the CST5 Mazdaspeed Turbo. Let’s see how and why below.

If you are unsure of the turbine wheel size, don’t worry, that will get covered shortly. For comparison, the MHI TF06 is very similar in size to the well-known GT30, but there are a few very specific differences that affect performance.

Turbine Blades

The first and most obvious difference is the number of turbine blades; this difference has a couple of benefits. First, less weight; even a small difference in weight can make a significant difference in the spool and transient response characteristics of the turbocharger. Second, reduce flow restriction; with one less blade, the “open” area through the turbine wheel exducer is increased, which increases the peak flow potential for top-end power.

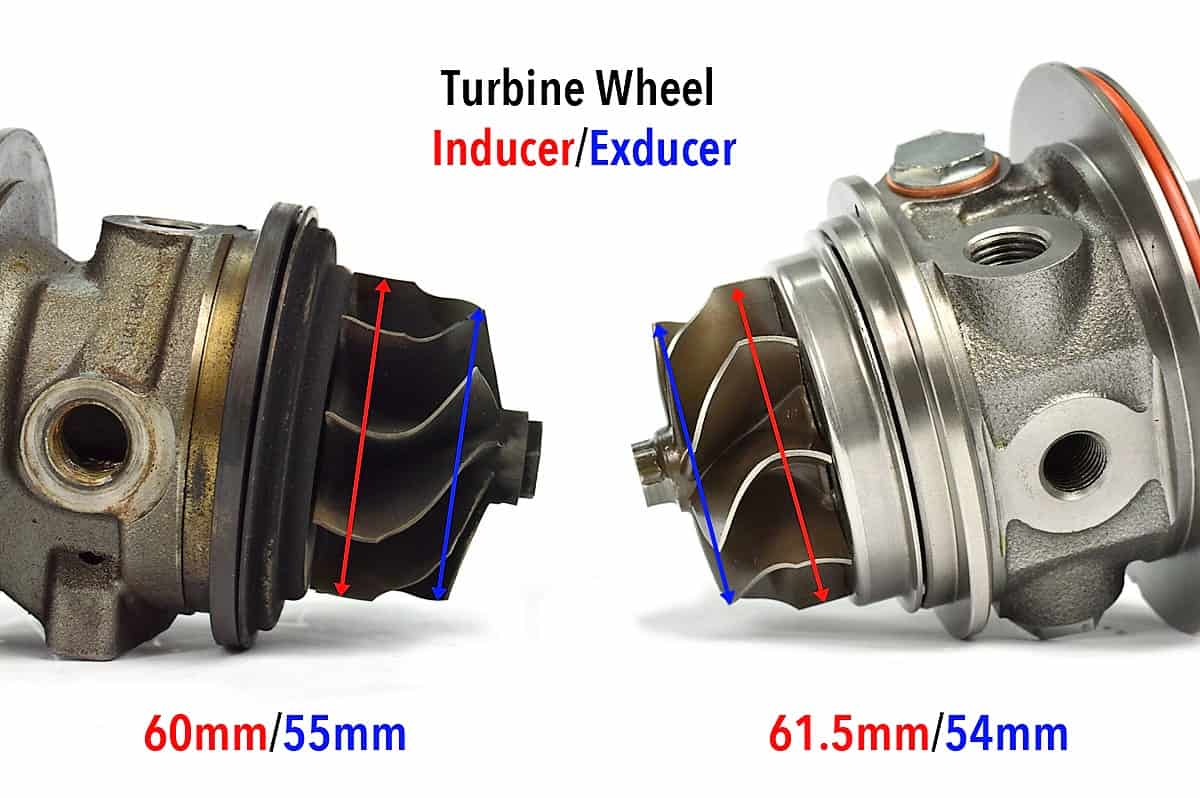

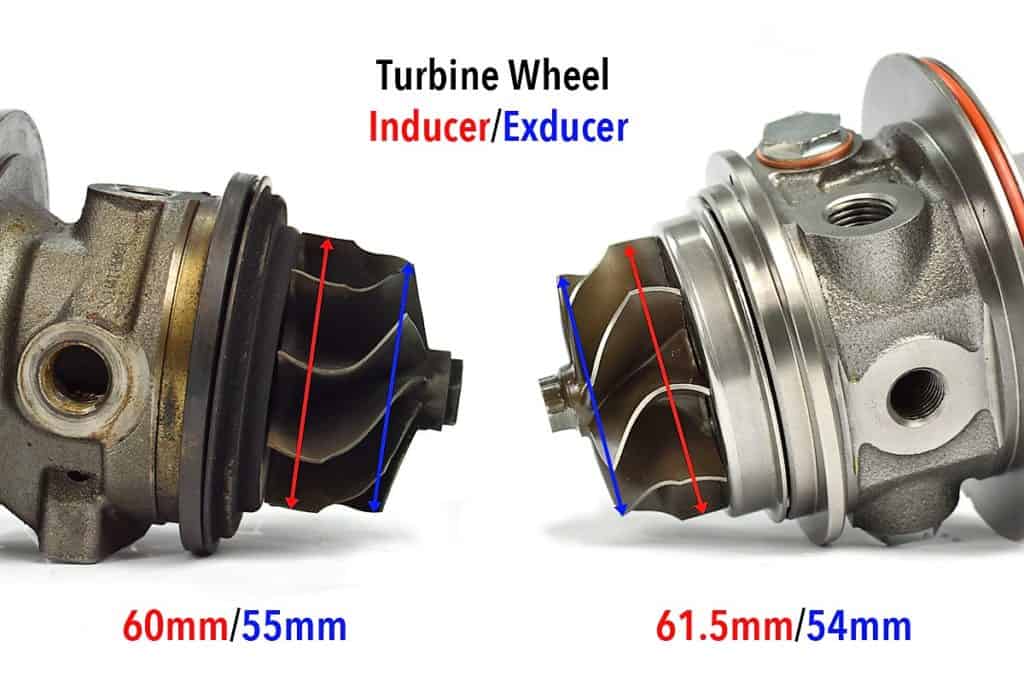

Mazdaspeed Turbo Inducer & Exducer

Next, are the less obvious differences. The GT30 has a 60mm inducer and 55mm exducer which equates to an 84trim turbine wheel vs the TF06 with a 61.5mm inducer and 54mm exducer which equates to a 77trim turbine wheel.

There are two key values to pull from this: First, the turbine wheel inducer directly relates to the peak flow of the wheel and the overall wheel size balance, which we will cover next. Second, the turbine wheel trim affects the spool and response characteristics of the turbocharger. The smaller the wheel trim, the faster the spool and response.

Size Matters in the Mazdaspeed Turbo

Alright, here is the most important and commonly overlooked aspect of a turbocharger. There is a rule of thumb when sizing the compressor and turbine wheels for a turbocharger.

If the turbine is too large, then the turbocharger will be very “lazy” and have trouble building boost.

If the turbine is too small then the compressor may be overpowering the turbine wheel causing excessive exhaust gas buildup that can rob power even though you may be running a very high boost pressure.

So what is the right balance? From our experience in turbocharger design, development and validation along with industry professionals we have consulted there is a rule of thumb we have found when sizing the compressor and turbine wheels. The exducer of the compressor wheel should be 10-15% larger than the inducer of the turbine wheel as shown in the image above.

So why does this work? Well, let’s look back a bit first. Many think you can just install a larger and/or higher flowing compressor wheel onto the turbocharger to make more power. Now that is true to a point, but quickly the approach becomes very inefficient for the engine. Forcing more air into the engine without improving the flow out of the engine can only go so far.

Everything that goes into the engine must come out, right? Increased A/R sizing and turbine wheel sizing is the key to exhausting all the gases from the engine efficiently, and efficiency is key to making power.

With both the CST5 and CST6 Turbo development, we focused on the overall performance of the engine, not just the development of a high-performance turbocharger.

Thanks for tuning in with CorkSport Mazda Performance, more to come…

Connect with us

You may also like

- The CorkSport CST5 is HERE!

- The CorkSport CST4 – The Best Turbo for the Mazdaspeed 3/6

- Best Mazdaspeed Turbo Upgrades – Choose Your Boost

- CorkSport CST4 vs. OEM K04