There has been a lot of buzz about the new(ish) turbocharged SkyActiv-G 2.5L first found in the Mazda CX-9 and now in the Mazda 6. Along with all this buzz, there are a lot of unknowns as well. Here at CorkSport, we’ve taken the step to try and address some of these unknowns. What is Mazda’s “Dynamic Pressure Turbo” and how does it work? There have been diagrams bouncing around on the internet, but no close-up view of the turbocharger itself. That’s about to change.

If you haven’t already read Daniel’s first installment, “Mazda Dynamic PressureTurbo an Introduction.” You wouldn’t want to miss out on the extra information before reading on.

The turbocharger found in the 2.5T equipped CX-9 and 6 is quite complex in design. There are many aspects to the OE turbocharger we could discuss, but today we are going to focus solely on the dynamic pressure system and turbine housing.

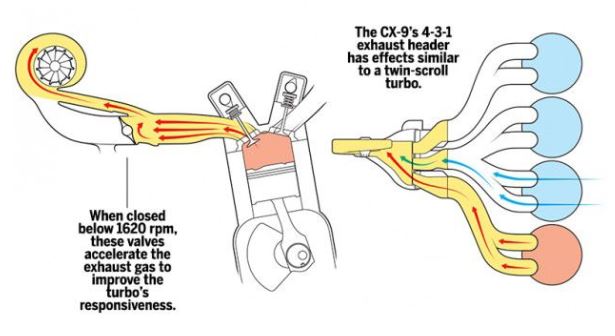

If you are reading this, then you’ve probably already seen various diagrams depicting how the dynamic pressure system works and showing Mazda’s clever 3-2-1 exhaust port design. If you haven’t, check it out below. Image credit to Car And Driver Magazine for the fantastic diagram.

Mazda’s 3-2-1 exhaust port design takes full advantage of the engine cylinder firing order. The advantage is improved exhaust gas scavenging for the adjacent cylinder (more or less the cylinder that just fired helps pull the exhaust gases out of the next cylinder that is about to fire). Ok, moving on; this is great, but how does the dynamic pressure system come into the mix?

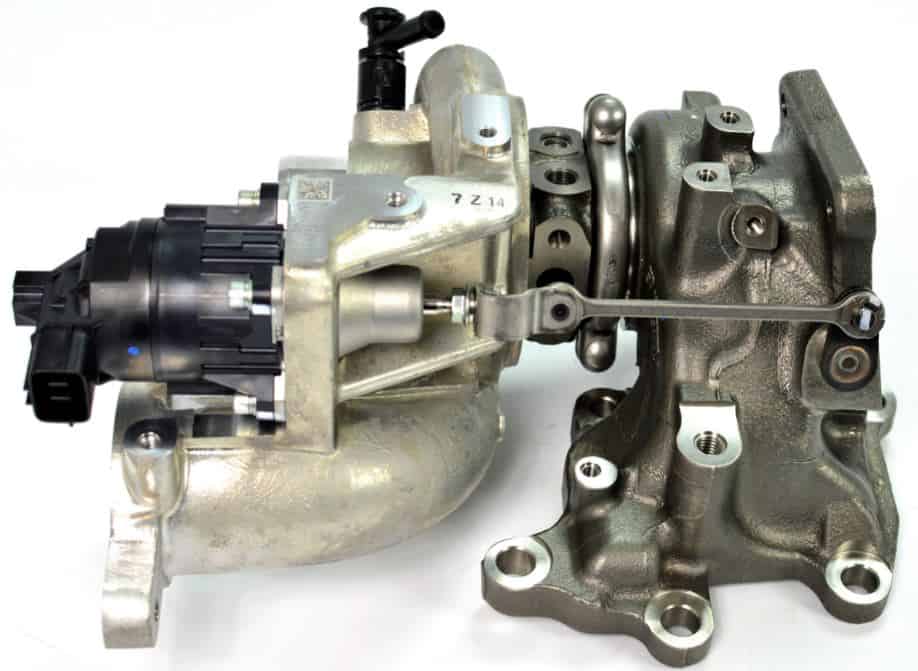

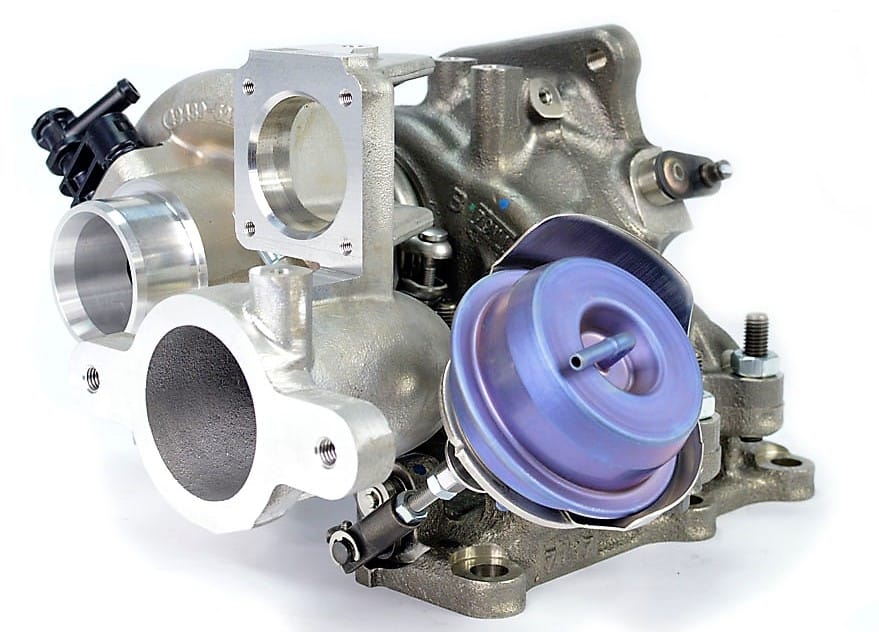

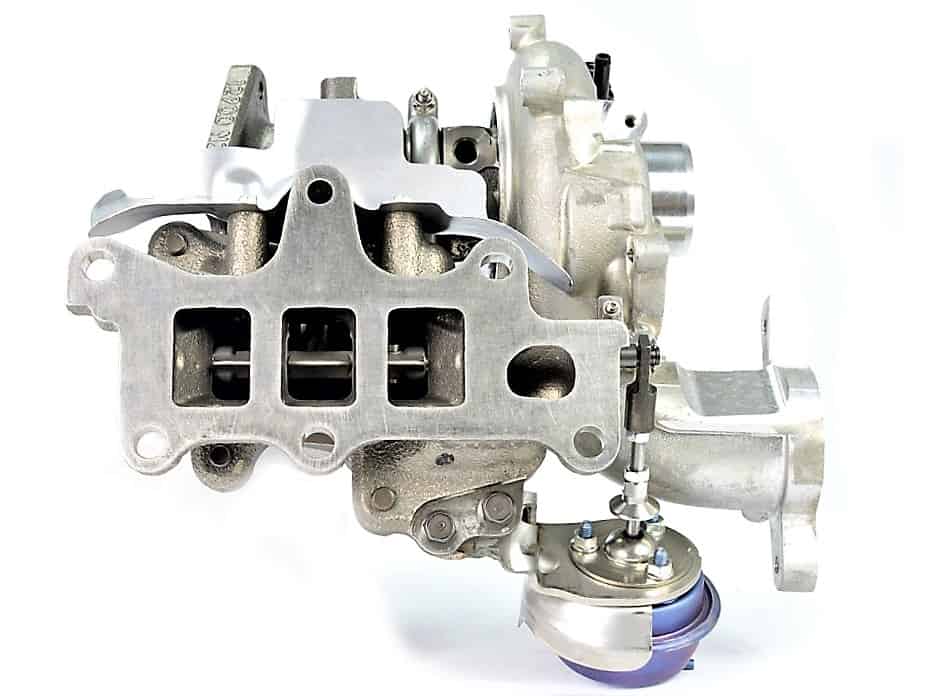

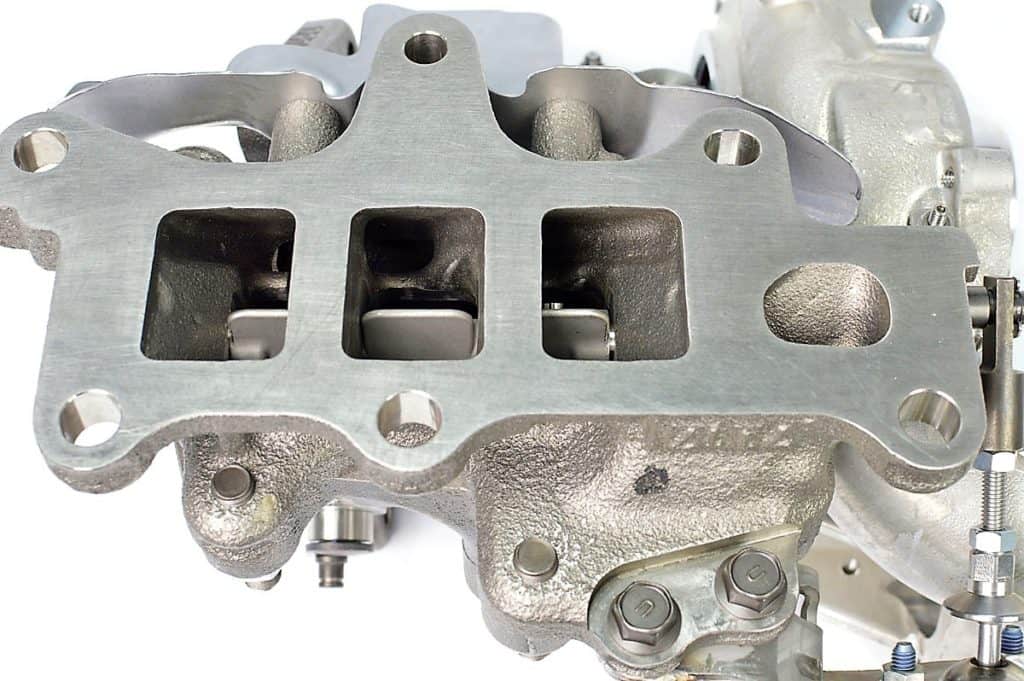

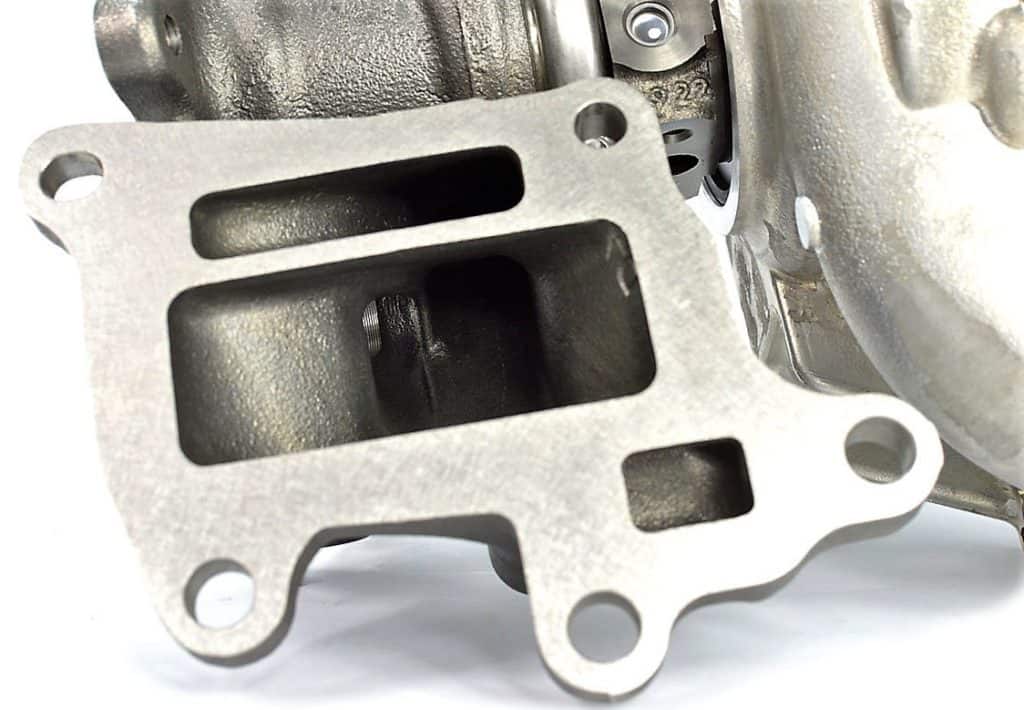

Shown here are the turbocharger assembly and the dynamic pressure valve assembled as one unit (the first two images also showed the fully assembled setup). The three ports are clearly visible along with the “vane” that passes through the three ports. This vane rotates depending on the engine RPM to control the exhaust gas velocity entering the turbine housing. The vane itself is controlled by the larger blue-colored actuator.

Now let’s take an even closer look. The vane does not open until approximately 1600rpm, but the engine cannot run if there is no exhaust gas can flow out of the engine. To resolve this Mazda has designed a dynamic pressure system with two exhaust gas paths. Looking at the above image you can see a small opening just above the vane. This is the sub-1600rpm exhaust gas path.

By reducing the cross-sectional area of the exhaust gas path, the exhaust is forced to accelerate through the dynamic pressure system and into the turbine wheel. This effectively reduces turbo lag, improving the vehicle’s response at low engine RPM. Once the engine revs past 1600rpm the vane opens, allowing the larger path to be used.

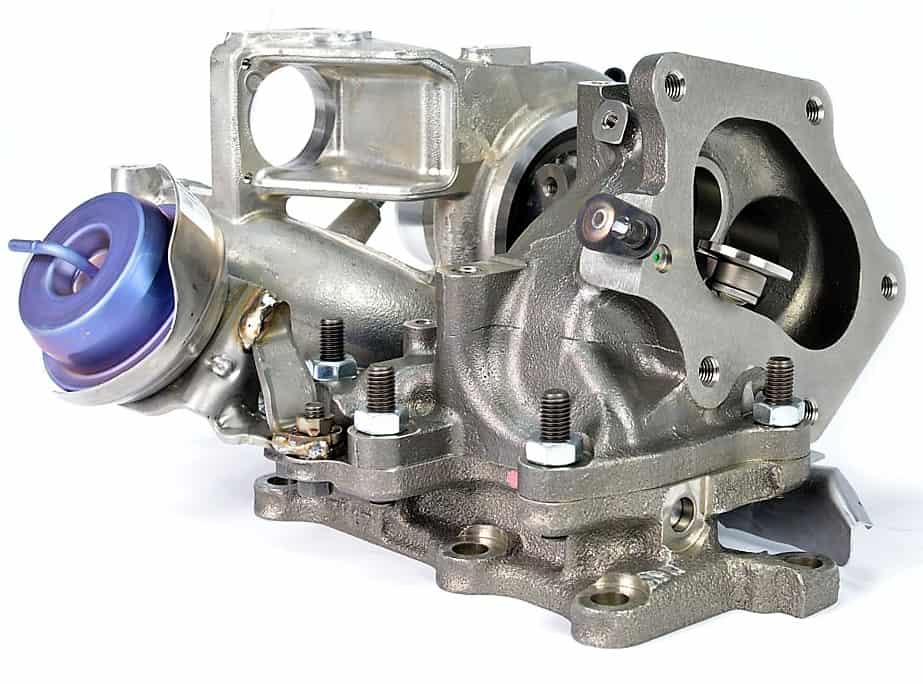

Here we show the turbocharger assembly (right) and the dynamic pressure valve assembly (left) separated. Looking at the dynamic pressure valve assembly, you can now more clearly see the three small paths above the larger path with the vane inside. Then look at the turbocharger assembly and you will see the small upper path and the larger lower path.

The fact that these two assemblies are separate systems is great news for the enthusiast. The development of a performance turbocharger will be much more feasible and the dynamic pressure valve can be retained with the performance turbocharger. One more detail to point out.

Mazda put a lot of thought into the design of the wastegate port; let me show you why. First, looking at the inlet of the turbine housing you can see a small vertical wall in the large path. This wall creates a completely separate path to the wastegate port which is very unusual on an OE turbocharger. Combine this design with a very large wastegate port and you get a design that can “waste” or divert an excessive amount of exhaust gas.

This tells us the SkyActiv-G 2.5L engine is creating a lot of (currently) unused exhaust gas energy. Again this supports the feasibility of a performance turbocharger suiting Mazda’s new turbo engine quite well.

Great things are on the horizon for the Mazda 6, now if only Mazda would put this engine in the 3 paired with a 6-speed manual transmission. Oh, one can dream.

-Barett @ CS

Connect with us

You may also like

- Mazda’s Dynamic Pressure Turbo – An Introduction

- Mazda 6 Turbo Down Pipe

- 2018-2021 Mazda 6 Turbo Lowering Springs 2.0