During our development of the new CST6, it became clear that an external wastegate (EWG) would be the only option for optimum performance and boost control — Read about the CST6 design here. Since we were already developing a housing for this turbo, we just HAD to make similar options for both the tried and true CST4 and the upcoming CST5. In today’s blog we will cover what makes the new CorkSport EWG Housings tick and go through how the systems are different from a typical internal wastegate (IWG)setup.

How The CorkSport EWG Housing Works

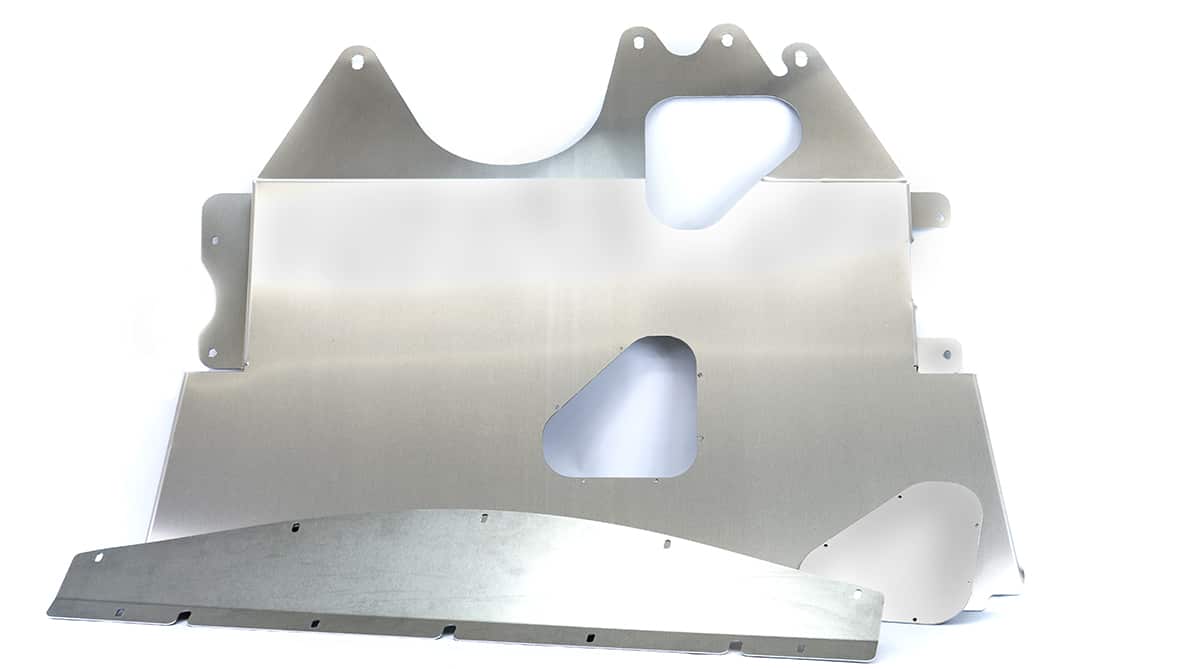

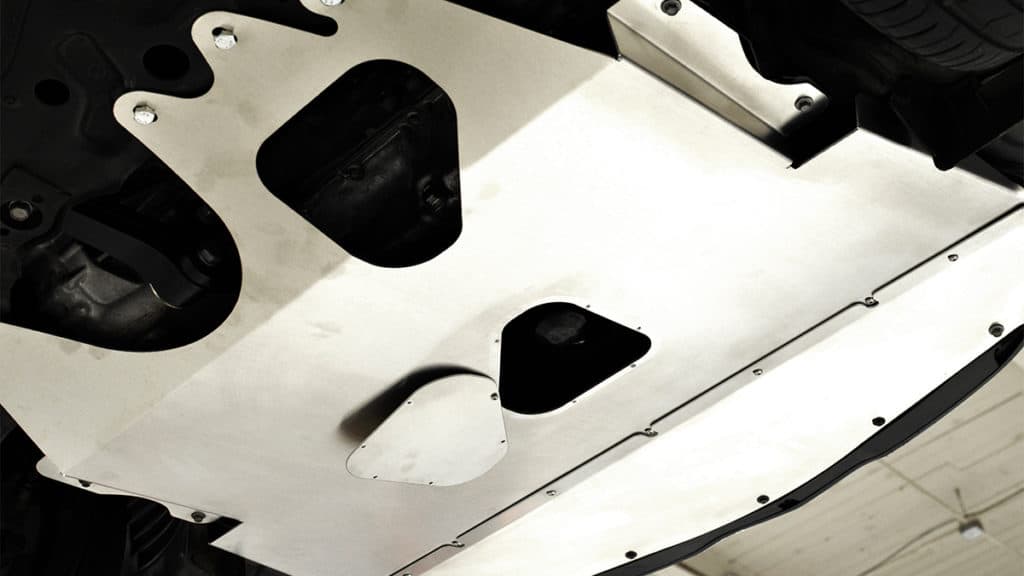

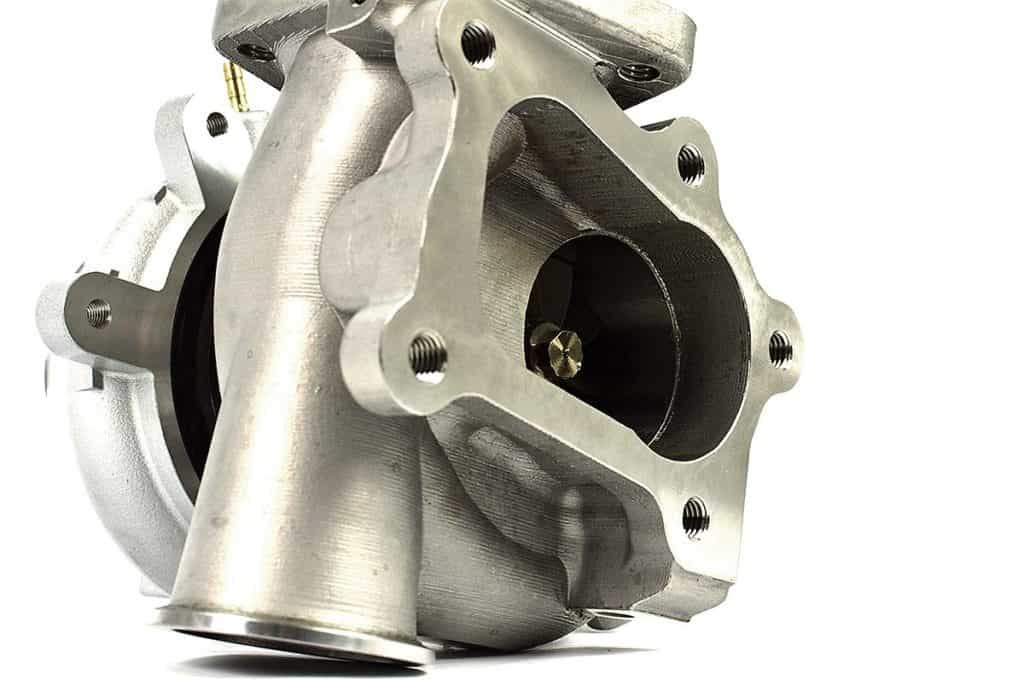

Starting with the basics, the CorkSport EWG housings replace the turbine or “hot” side of your CST4 or CST5 turbocharger. The CS housings eliminate the small “flapper valve” of the internal wastegate with a path to a standalone wastegate actuator. While the housings will not come with the actuator itself, they will include everything you need to mount up a Tial 44mm (or equivalent) EWG, with the option to grab a screamer pipe to go with it.

EWG Housing Placement

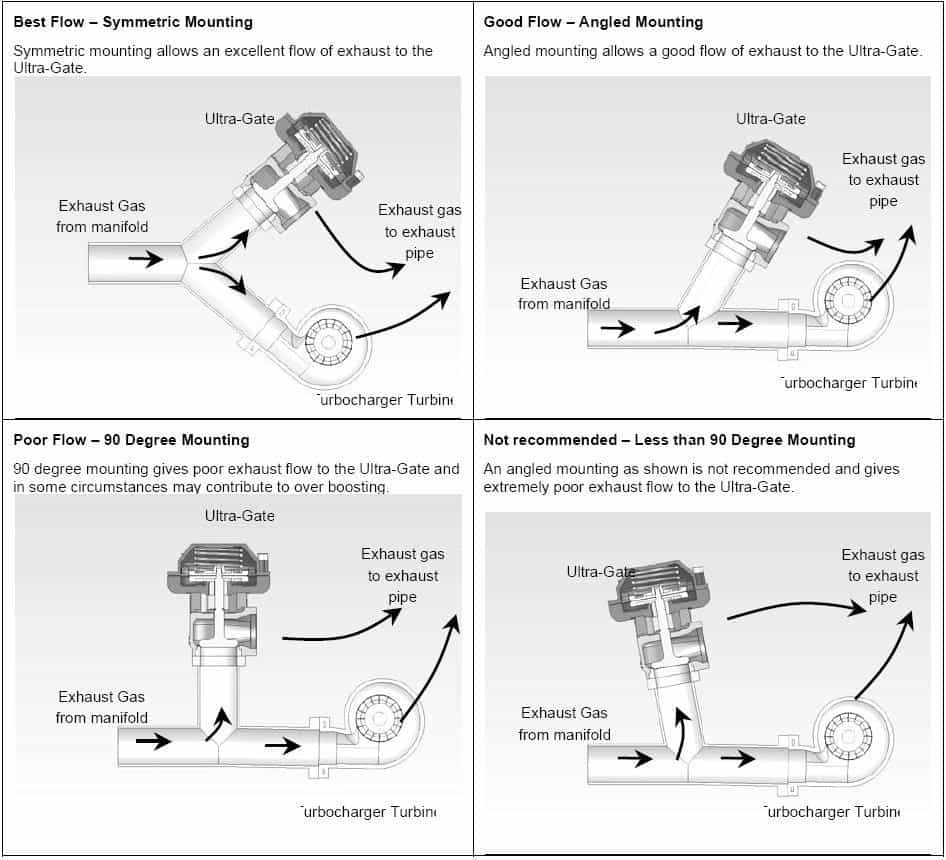

The placement of an external wastegate is very important for proper boost control. We chose the location of it carefully as the offshoot from the scroll of the turbine provides an optimum path into the wastegate. As shown in the diagram below, a shallow angle into the wastegate offers the best exhaust flow path which results in optimum boost control.

Click to Expand

A Properly Sized Wastegate

Sizing is also important for boost control. Too large of a wastegate is hard to fit on the car and can be difficult to control boost as it does not need to open much to flow a lot of volume. Too small of a wastegate can cause over boosting from a lack of flow. For most Mazdaspeed applications, 38mm and 44mm sized wastegates are most commonly used. We chose the 44mm option for its better usability on the street. Since a street car is not using the turbocharger at peak efficiency 24/7 and is usually at a relatively low boost level, the larger 44mm wastegate will more effectively vent the excess exhaust gases.

Choosing An Internal or An External Waste Gate

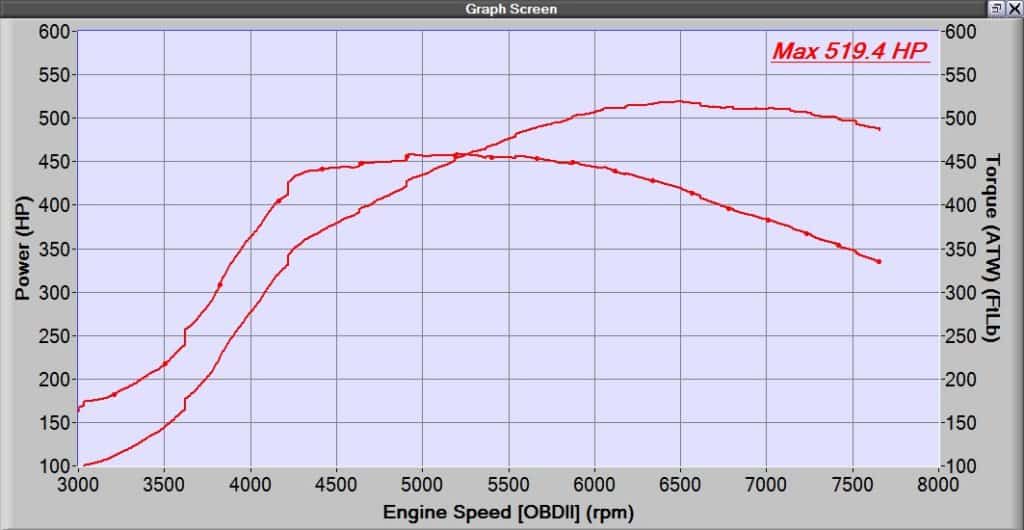

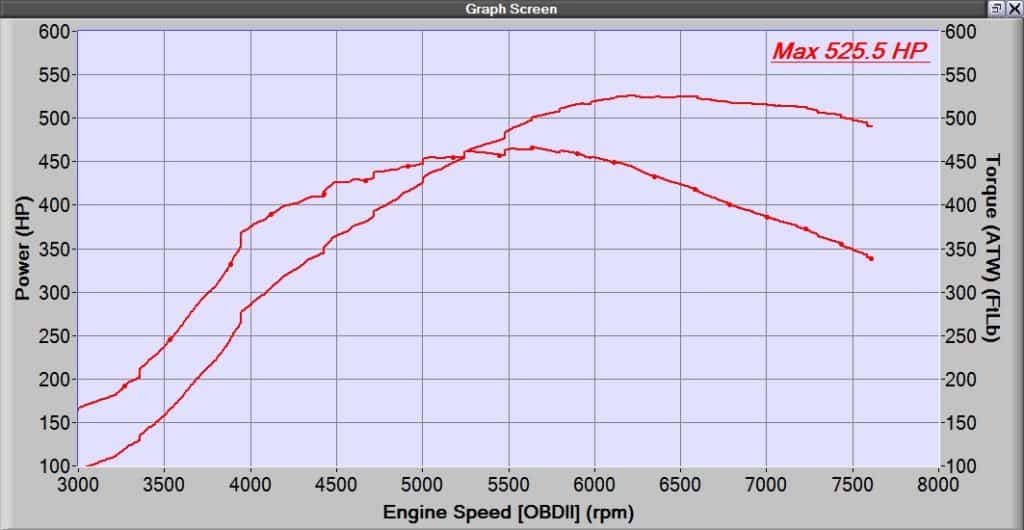

Now on to a big question: why an external setup over and internal setup? While they both have their pros and cons, the biggest answer is better boost control. In general, an external wastegate setup will control boost more accurately and respond quicker to changes in boost than an internal one. While the CST4 Turbo and CST5 Mazdaspeed Turbo have been optimized to work with IWG, an EWG setup will almost always have better boost control. It should be noted that, generally speaking, an EWG will have higher peak power capabilities. First, back pressure in the exhaust system is reduced due to the removal of the exhaust gas that would usually cause turbulence as it exited the IWG right near the turbine exit. Second, an IWG setup can reach a limit in flow where literally no more gas can flow through the turbine & IWG port. Most EWG setups do not have this problem as the EWG port can be larger & the wastegate gases do not have to exit in the same location as the turbine gases.

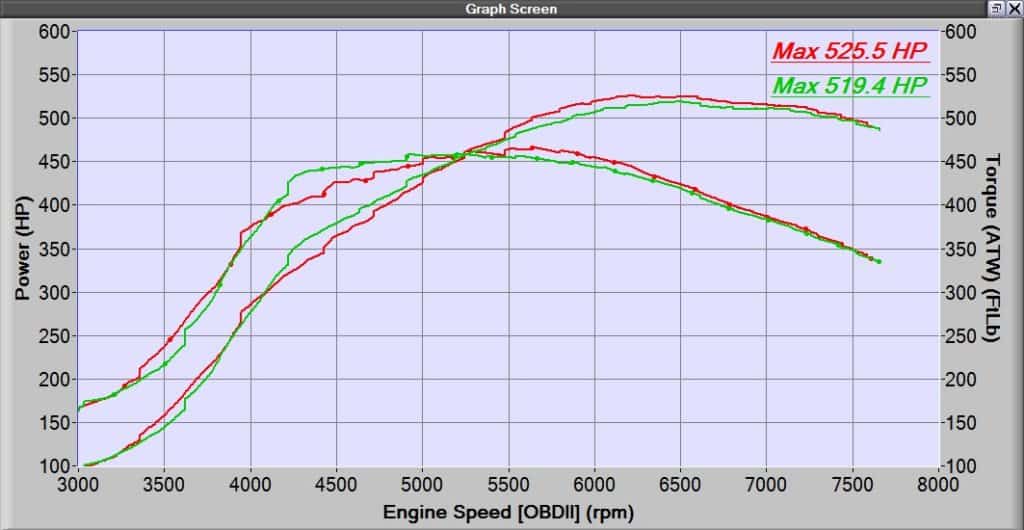

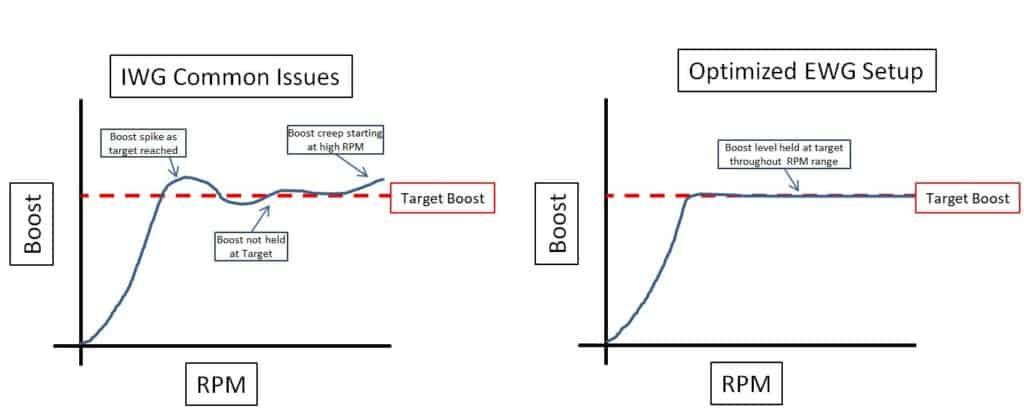

Check out the diagram below, as it illustrates a common problem with internal wastegate setups. A boost spike as desired pressure is achieved then inconsistent boost as RPM increases. External setups (right diagram) typically do not have either of these issues and can achieve a near flat boost curve.

(Right) External Wastegate Setup | Optimized Setup

Click to Expand

The CorkSport External Wastegate Design

Moving to an EWG design allowed us to tweak the design of the housing itself. The CorkSport external wastegate housings all use a ~0.82 A/R. This number is a ratio that is determined by the geometry of the scroll. I won’t go too much into it, but for more info be sure to check out Barett’s turbocharger white paper here. This is larger than the CorkSport internal wastegate setups. Essentially, the increase means you may sacrifice a little bit of spool time but gain peak power capabilities at high RPM.

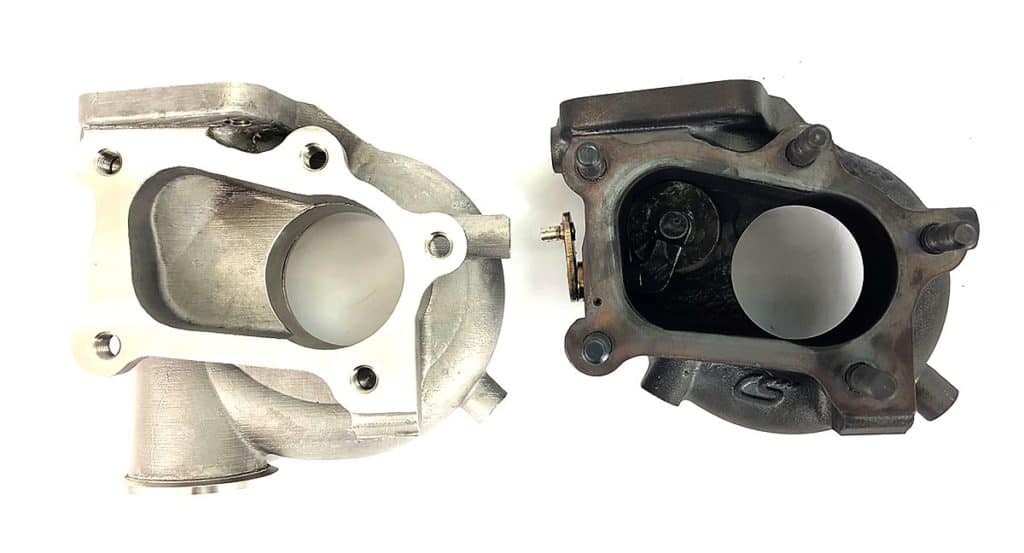

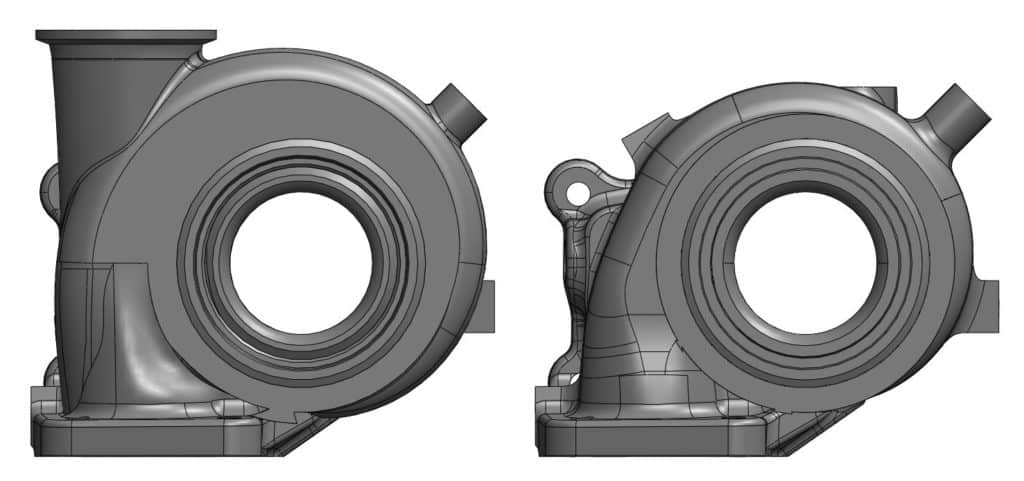

In addition, the volume of the scroll itself was increased. This is referred to as “swallowing capacity”. By increasing this volume, the turbine housing will be able to air more efficiently at peak, again increasing your max power potential. This is especially important when you have a high flowing ported head or an upgraded exhaust manifold. Check out the CAD models below, you can really see the difference in the scroll size.

I almost forgot the best part! An external wastegate setup gives you the option to run a screamer pipe which sounds amazing while under boost. While screamer pipes are sold for race use only, they add far more excitement to a wide open throttle pull! Stay tuned for more, next time we will be sharing testing information & some more teaser shots.

Connect with us

You may also like