Good day, my fellow Mazdaspeed enthusiast! In today’s tech blog, I want to talk about fuel pump internals. No, I am not here to debate whose internals are better or what brand offers what. I am here to help you track down and correct your low fuel pressure issue.

Now, it’s no debate that anyone who’s anyone in the Mazdaspeed community will always recommend a high-pressure fuel pump internal upgrade before you start to go crazy down the mod list. But why do we want them and, more importantly, how do they work? I can confidently say that a majority of people who buy and install upgraded fuel pump internals do so simply because they are suggested it by their tuner, a forum, or a friend, but a very small percentage of people understand how they actually work, and how to correctly diagnose a problem should they ever have a fueling issue. So, grab a seat, and let’s dig in.

How Fuel Pumps Work

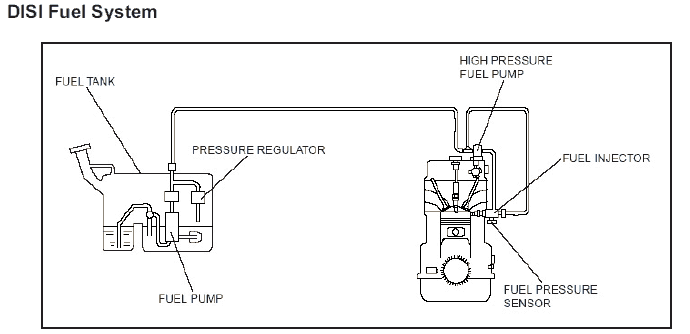

In order to get the best understanding of the fuel system equipped on these DISI engines, I find it best we start at the very beginning, and the very beginning is in the fuel tank in the rear of the car. Both the Mazdaspeed 3 and Mazdaspeed 6 are still equipped with your modern electric in-tank fuel pump. This fuel pump is a constant pressure fuel pump that can operate on two different voltages, high and low. What this means is that the Powertrain Control Module (PCM) can send low voltage to the pump for idle-like conditions when less fuel is required, and high voltage for high-flow conditions such as wide open throttle. But in both instances, we are not changing fuel pressure, just changing the amount of volume we are sending to the high-pressure fuel pump housing. It is important to note that. The fuel pressure generated by the intake fuel pump is in the 55–71 psi range.

As the fuel exits the tank, it travels through your standard-style hard and flexible fuel lines up to the entrance of the HPFP. Now, here is where the real fun happens. The low-pressure fuel first goes through a pulsation damper to help smooth it out and get rid of any tiny air bubbles that may exist and to help stabilize it before it moves on to the spill valve. The spill valve sits on top of the housing, and the best way to think of its operation is just like a tiny fuel injector. The amount of fuel we are feeding into the pump chamber is all controlled by the actuation of this valve. The valve is controlled by a spill control solenoid, which is the black plug on top you are all familiar with. The PCM energizes this solenoid, which lifts the spill valve off its seat and allows fuel to enter into the fuel pump chamber. When the PCM de-energizes the spill valve, the pintle is forced short with the assistance of a return spring.

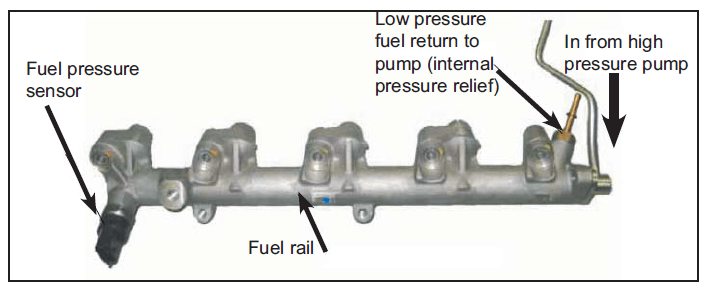

At this point, the fuel is now isolated in the actual fuel pump chamber and is ready to be compressed and have its pressure raised to feed your fuel rail. As the engine rotates, the trilobe on the end of the intake camshaft drives the HPFP internals and compresses your fuel. Once the fuel is compressed, it now goes out the bottom by overcoming another spring and check ball. This spring is to make sure that fuel does not back feed into the fuel pump housing exit. This now pressurized fuel goes to your injectors and makes power. Any unused fuel returns back to the entrance of the HPFP via a pressure relief valve that sits on the fuel rail.

Diagnosing Fuel Pump Issues

Get all that? If you did, then good. If you didn’t, then reread it a couple of times to absorb all the material. It’s good stuff to know. Now, let’s start down the diagnostic path of trying to determine why we are having low fuel pressure issues.

- With the key on and engine off (KOEO), you should have 55–71 psi registering on your Accessport. This pressure should hold steady for a few minutes until the EVAP system slowly drops the pressure and everything leaks back down. If you don’t have any pressure reading at all, or a value much lower than that, expect a fuel delivery issue in the tank. This can be caused by any of the following:

◦ A bad in-tank fuel pump.

◦ A bad fuel pump relay.

◦ A clogged fuel pump filter.

◦ Faulty wiring and connections. - If you are having a lower than normal high-pressure fuel reading, such as always seeing 1,000 psi under all conditions even at WOT, you can expect either a mechanical or an electrical issue. The following are things to check:

◦ The condition of piston and sleeve. Look for any scuffing, scoring, or galling.

◦ The condition of the cam bucket. Look for any abnormal wear or damage.

◦ A sticking spill valve that is not allowing the correct amount of fuel into the chamber. (This is especially true on high-mileage cars and on cars where guys run lots of ethanol.)

◦ A stuck-open pressure relief valve.

◦ A broken seal screw O-ring or an improperly torqued seal screw. - If you are having an odd intermittent issue such as fuel pressure fluctuations that bounce around from 400 to 1,500, or something of that nature, then expect the following:

◦ A sticking spill valve that is not allowing the correct amount of fuel into the chamber. (This is especially true on high-mileage cars and on cars where guys run lots of ethanol.)

◦ A stuck-open pressure relief valve.

◦ A bad HPFP housing check valve exit.

◦ Damage to the HPFP internals themselves.

◦ A broken seal screw O-ring or an improperly torqued seal screw.

Inspecting For Damage

Checking some of these things is simple, such as the internals themselves and the seal screw. Confirming the physical condition of the internals will require the removal of them. We cannot tell if they are good or bad simply because of a low fuel pressure reading. The whole assembly works as a unit, and if any one of the above-mentioned things is bad, then the fuel system will not operate as intended. When removing the fuel pump internals, look for any signs of scoring, seizing, or scuffing. Any of these can actually be indications of an even bigger problem. It is rare for internals themselves to just go bad on their own, and in most cases, the units had a drop in lubrication that leads to excessive heat and premature failure.

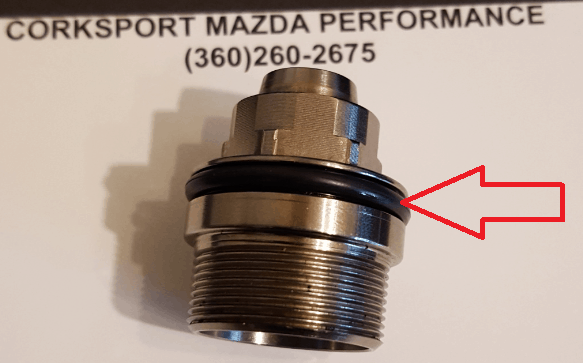

Also check the condition of the seal screw. If the O-ring is bad, it will have a tear or pinch in it, and your oil can begin to develop a gas-type odor and can thin out. You will want to replace the O-ring and change the oil if this is the case. As for the other components, there is no easy way of testing them, and in most cases, if any part of the housing itself is bad, you are more than likely looking at replacing the pump as a unit.

I hope this gives you guys a little more clarity on the fuel delivery system and how it all works. Should you have any questions or comments, drop us a comment below.

– CorkSport

Question: If you dont have any upgrade and the first one is the hight pressure fuel pump upgrade. Theres gonna be any problem with the injection? Do you gonna leak and lose more fuel by the injectors? or all the sensors control the fuel presure and its going to work as a normal one until perform the changes?

The system has a spill valve so there will be no problem with the injection. The bigger problem is not getting enough fuel which is why the upgraded pump internals are needed.

How do the replacement parts create more flow AND pressure? How long will they last? Are they E85 compatible?

Check out our white paper on the fuel pump internal design.

Link

Is it E85 compatible?

In the morning my car has a hard start and tries to stall. But once the car is warm it idles perfect. When I try to start the car when it’s warm it’s very hesitant. Ecu fried, got a used ecu and ever since then car is slower and has this starting problem. Help! Haha

Also according to the accessport I’m getting no voltage to the hpfp sensor

Give us a call at 360-260-2675

What is the compatibility with E85?

I have a 2008 mazda speed 3 and I am having a problem with the fuel pressure just dropping out after a few minutes of running. I have replaced the in tank fuel pump. the HPFP, the HPRV and the crankshaft sensor and still the same thing happens. What could it be?

Hi, my car also reads 0 volts to the split valve. I think its just a error with the ap but if that was the true case then you wouldnt have fuel pressure. It is strange to say the least. I have cleaned grounds and sensors and everything with no luck.

Did u check the relay? It stalls when it warms up correct? Look on msf. Some people have been having this issue lately.

Joey, The internals are E85 compatible, but if you plan on running it in your fuel system I always recommend the addition of an extra inline fuel filter to help keep containment’s from entering the HPFP housing.

I recently had my motor rebuilt. My hpfp apparently worked when he had it built but when I got the car back I couldn’t accelerate as it would bog and hesitate. I looked st accessport and as I drove my hpfp pressure was around 60-70 psi. I then monitored my hpfp sensor voltage and it was at 0. What could my issue be?

I just installed my HPFP internals yesterday and broke the internals in with a 100 mi cruse keeping the loads lite (under 3000 rpm before shifting) and noticed a fuel pressure range on my accessport that concerns me. Is there an optimal pressure range that would let me know the install was a success? I have not tried a WOT scenario yet.

Hey guys,

I recently purchased the corksport internals to go along with my new motor, and when i started it for the first time, all boost leaks and fuel leaks and seal screw oring everything was 100%, but i was getting a really bad erratic idle and was pig rich. In many conditions under throttle you would hear like a banging or a pop of some sort, i was thinking maybe it could be a leaking injector, turns out i pulled the rail and the injector closest to fuel pump was leaking bad like it was pushing itself out under high pressure and i believe thats what was creating the noise? Am i correct to think this? And my other question is, could this have been causing the extremely rich condition and erratic idle? Thanks

Too add to the above comment, i only was getting the rich situation with the corksport internals, i swapped the stocks back in and it went away but it still at that point had the popping noise under certain throttle occasions, so am i to believe that with the new internals it caused a worse leaky injector with the stronger pressure causing the injector to leak constantly and causing a rich erratic idle? Sorry if this is hard to understand, but its not the easiest to explain. Thanks, but like i said i found i had a leaking injector seal and it seems like the sound was coming from that area. So im planning on ordering the corksport seals, but i was curious though as to with the new seals, would it be safe to reinstall the corksport internals believing that the new seals will have corrected the rich idle state?

Have a question, Have a MS3 2010 that was bought used. Was told it had Corksport internals. My fuel rail psi at idle is 400 to 420 and at load spikes up to 2070 psi. Have not cracked my fuel pump open to visually confirm because the psi is matching what big internals should be pushing for psi. My MS3 has ko4 rebuilt with Bigger seals journal bearing and CHRA billeted but only running about 20PSI. Also 3″ DP with Racepipe, Weapon Cold AIR, Bigger MAP, Turbo Inlet and Weapon Turbo manifold. Putt a cobb AP on with Stage3 tune. After a week I Started getting hesitation from 2900 to 6500 rpm like it was blocked or was not getting fuel. Swapped to stock tune and everthing was right again. Fuel internals? Bad Pump? Sounds like I still have oem internals. Please give me your thoughts.

Hey corksport,

I’m having an issue with my fueling I don’t have the fuel pump internals yet, however I have a check engine light that says cylinder 1 misfire, and injector 1 circuit fault. Sometimes the car loses all acceleration and will idle below 500rpms mazda said that it could be the injector, then my buddy (he owns shiftfast Motorsports) said it’s a common issue for these pcm systems to have electrical problems and that I’d have to replace the pcm because it’s sending the wrong signal and the injector maybe stuck open because of that. Current mods: Corksport Stage 2 intake, and RMM

The PCM having electrical problems is pretty rare on these cars. Due to the fact that you have a CEL pointing directly at the injector, then i would take it somewhere and have them check to make sure it is getting constant power. Try that and go from there 🙂

Please help! My 2008 Mazdaspeed 3 has very rough idle because the fuel pressure is around 80. I’m also getting a loud chattering noise from the hpfp. I thought it was bad so I replaced the entire hpfp with CPE. Still no fix. Could this be the fuel pressure relief valve?

That does sound like the pressure relief valve.

I’m having an issue with a intermittent fuel pressure drop. I have gotten the code P0089 for the fuel pressure regulator. There were times where this drop would last 5-10 minutes. My pressure goes down between 60-75 psi. If I shift into neutral and Rev alittle bit it goes away. I started to poke around looking for any obstructions on any vacuum /fuel lines…. Connections on sensors or anything visual I could find that was obvious. Tightens all hose clamps and sensor connections and my car ran fine for about two weeks…. Thought I remedied the issue. Now it has come back only dropping fuel pressure for maybe a second or two. And this happens maybe once a week. Does any of this sound familiar or helpful to diagnose? My car is pretty well built and I’m running autotech fuel pump internals

Please help!!!!!

My 2012 MS3 RPM’s are dipping and the car seems like its choking, but isn’t dying. Could this be a sign of a weak HPFP or anything in that nature? I have a new HPFP Sensor, new O2 Sensors, EGR Valve, and much more. But now, whenever I even touch the gas it starts to choke and the RPM’s dip up and down quickly, sorta like as if I was touching the gas and letting go constantly, but won’t die. I have the HPFP Internals with me, just trying to figure out the issue first. PLEASE HELP

give us a call directly! 360 260 2675 the guys are always willing to help!

I really appreciate your efforts put in this blog post. You have shared the huge information about High-Pressure Fuel Pump Troubleshooting. Keep it up!!

I would like to know your fix on this

hi there i have a 2007 mazda cx7 with a fault code “fuel pressure sensor low input” this issue occurs when the vehicle is cold. under current data the rail pressure reads 0 and the pressure sensor sits at 0.3V while running erratic? any help on this would be appreciated

Sounds to me like the sensor itself is starting to fail. I’d start with the sensor, and if that doesn’t correct the issue we will look at some of the regulating devices.

All the information which have you shared with us is really very helpful for me and my business. Thanks

I have the code p0452 in my gen 2, code is for fuel tank pressure sensor low circuit, what do i need to change.?

I’d recommend looking into replacing the fuel tank pressure sensor and then go from there.

Just replaced hpfp internals with corksport internals. Was wandering what pressure should be at idle. I’m around 400 psi at idle and 1600-1700 at normal driving speed around 2500 rpms. Thanks. Have a great day.

The numbers sound fine.

Installed the CS HPFP internals last week. Two days easy driving they were great. CS Stage 1 Tune on the Accessport. Third day got a bad cut out and fuel pressure started intermittently dropping low. In neutral and slight gas went back to normal but same thing happened multiples times. Checked all the connections, everything seems ok. No smell of gas. CEL light on with a code of P0089. Thinking this is a Relief valve issue or the fuel rail sensor?

i have a question, i have replaced a high pressure pump into my mazdaspeed 3. but my AFR still running low at 9.45.. need help please…..

Basically I think I got bad gas. The car would start. Stay on for a little while then die once it gets to operating temperature. And it won’t stay on if it’s hot. Did that for a day. Then the next day it wouldn’t stay on at all at idle. The only way it would stay on is to give it full throttle. N it wouldn’t even go past 700 rpm. And it was missing really bad. Then I drained the gas. Cleaned everything. Then put new gas. Same thing. And it would give out black smoke. Then finally I unplugged the hpfp connector then it would start normally. It drives. But it doesn’t hit boost at all. And every time I plug in the connector of the hpfp. It dies. I bought a pump thinking its the pump. But it still does the same thing if the pump is connected. I thought it was the relief valve. I took it out to test it. But I cant blow into it at all. Now, idk what is wrong with it. And the crazy thing is that I still don’t get any hpfp reading from my accessport since it wouldn’t stay on at all. It’s always 0 since it started missing.

We have a cx-7 2.3 that is filling the oil pan with fuel. after a few drives the level on the dip stick is way up. would the high pressure fuel pump leak fuel back into the crank case? is this common?

Thanks

Yes, pressure in the crank case caused by excessive blow by. Perform a leak down and compression check on the engine.

Did you ever find out what the problem was? This is exactly what is happening to my 2007 Mazdaspeed3. I just reassembled it was idling from cool, then once it was at operating temperature it died. And what to start back up. I look at the fuel rail psi and I have 14psi even after trying to start it a few times. And it’s not going to start with 14psi. You could really get your car to idle without the HPFP plugged in? Any help or update to your issue would be great.

My 2011 MS3 is doing this. I have the CS hpfp internal. Did you ever find what is causing this?

Good morning everyone, I have a question in my MS3 2011 Turbocharged I just removed the catalyst but I still use the original factory pipe when one is going to remove the catalyst from this car there is q deceive the oxygen sensor which is under a cable? Quite far away? Can you put 2 spark plug extenders? Or is there no q deceive you? What I did was q grab the original pipe and damage the entire filter this and q was covered both filter q goes up and q goes lower

Hi Jules. I have the very same problem. And I was wondering did you ever solve your issue ?

2010 Speed3, (CorkSport HPFP, Downpipe, Accessport Map, New Mazda injectors) 90k miles

After doing the above mods, it ran for around 10k miles.

Now, its loosing fuel pressure. in tank pressure intermittently goes to “0” after a few minutes or sometimes several miles.

Used mechanical pressure gauge to verify loss of pressure. Replaced in-tank pump with Mazda part. Replaced all relays and fuses. replaced Fuel Pump Resister, (also jumped Fuel Pump Resister).

Is the power to the in tank pump turned off by the computer, or what else interrupted the power to the in-tank pump. (But, I did not check the voltage at the pump.)

Why would I get 70psi to 15psi to zero. Will not restart, fuel pressure is at “0”. Wait five minutes and it restarts, pressure is at 65/70psi at idle. (yes, I replaced the complete pump assembly, Mazda part) with the same results.

Need some help !

i have a 2008 cx-7 and when i start it it surges idles rough and sometimes dies. it only does this if the engine is cold once it gets up to operating temperature it runs ok. obd code for low fuel rail pressure is present. any recommendations? please and thanks