Check out the the Best CorkSport Mazda 3 Cat Back Exhaust for 4th Gen models (2019-2024)! Building upon the already great CS Axle Back exhaust, the Mazda 3 CBE replaces the entire OEM exhaust system from the header back with high flowing 63.5mm piping and flow-thru resonators. This adds an aggressive sound that is great for tearing up the backroad, yet is still comfortable for cruising on the daily commute. Read on for more details and be sure to listen to the sound clips below.

The Mazda 3 Cat Back Design

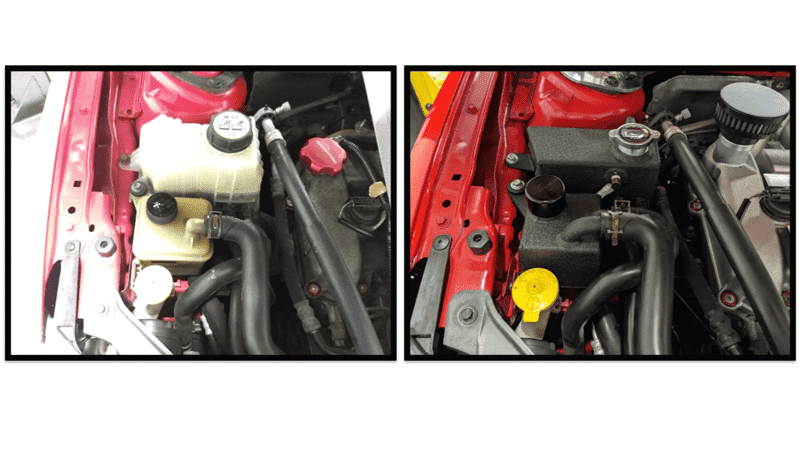

The primary focus of the CorkSport cat back is to add a great sound that spices up your new Mazda 3. The restrictive OEM axle back exhaust is replaced with the unique CS Mazda 3 Axle Back Exhaust. The large resonator eliminates the drone fantastically, while the asymmetrical design offers a great tone and interesting exhaust notes. Moving to the front, the OEM, mid pipes are replaced with full 63.5mm (2.5”) mandrel bent piping that incorporates a large oval-shaped resonator. This resonator was chosen for its ability to eliminate any drone and undesirable sounds while retaining a straight-thru design to remove any exhaust restriction. The result is a sound that is louder and more aggressive than the CorkSport axle back alone, without being annoying or bothersome on long drives.

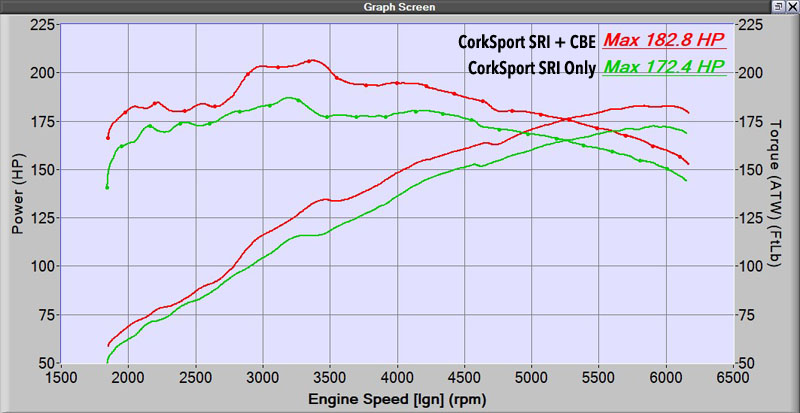

Cat Back Improves Performance

The increase in volume also comes with an increase in horsepower. The axle back alone was able to net 3-5WHP across the RPM range. In our testing, the Mazda 3 Short Ram Intake was installed with both the OEM and CorkSport Cat Back Exhaust. With the removal of the restrictive OEM mid pipe and mid pipe resonators, the CBE netted us approximately 20wTQ and 10-18wHP in our testing!

Easy Installation

While both improvements in power and sound are great, they mean nothing if it’s a pain to install. Don’t worry though, the CorkSport cat back exhaust installs just like the OEM exhaust. We used both a FWD and AWD exhaust system during our development to ensure correct fitment for whichever drivetrain you have. While the pipe routing of the CS mid pipes are slightly different for the different drivetrain options, the resonators setup is exactly the same, so you can be confident that both AWD and FWD Mazda 3’s sound fantastic.

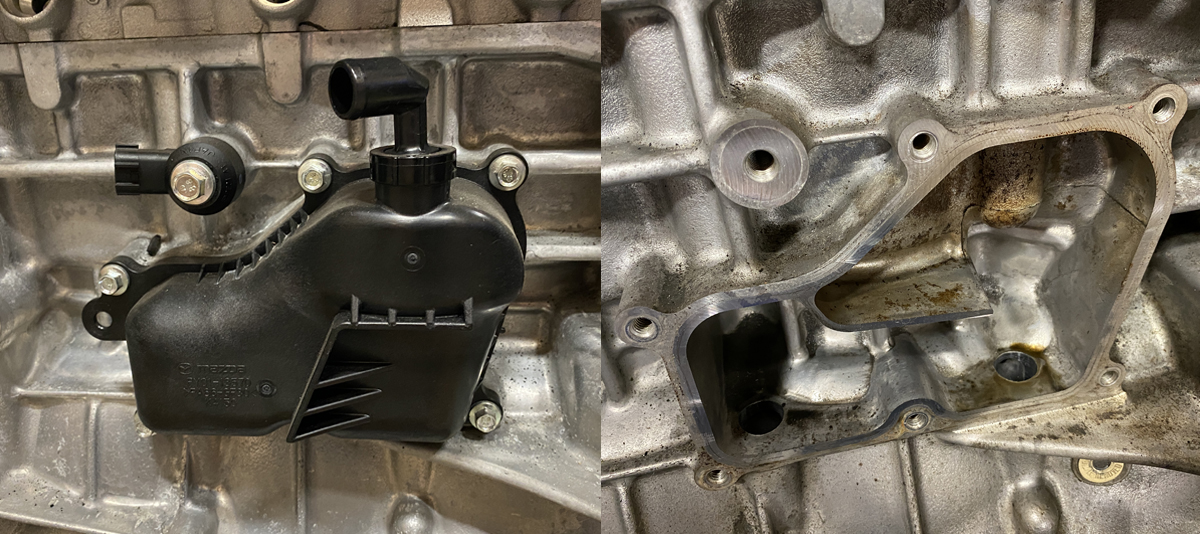

If you have a Mazda 3 with Cylinder Deactivation, this is not an issue with the CorkSport CBE. We include a bracket made from 304 stainless steel, which holds the cylinder deactivation motor securely up and out of the way. The purpose behind this bracket is so that no check engine lights are set off by having it disconnected and also to get rid of the extra complexity and restriction of having a valve in the exhaust.

Cat Back Provides Best Mazda 3 Fitment

Like the CorkSport Axle Back exhaust, the CS cat back exhaust system has a variety of tip options to best suit your vehicle setup. We have different tip fitments for hatchback, hatchback with the OEM Mazda aero kit and sedan. The sedan tip option is the longest in order to fit the longer rear end of the sedan models.

We specifically designed two different length tips for the Mazda 3 Hatchback due to the design of the Mazda Appearance Package. The rear bumper skirt adds a lot of length to the car…hiding the tips from view. With the Appearance Package-specific design, the tips are prominent in the rear bumper skirt as they should be. (The Hatchback Appearance Package tips are 45mm longer than standard Hatchback tips).

Each setup uses a different length to ensure great fitment no matter your car. All tip options use a 90mm tip diameter to help fill out the bumper cutouts. Plus, each tip is finished off with a laser-engraved CorkSport logo plate to give a great look.

Cat Back Exhaust’s Quality Finishes

As with all CorkSport exhausts, the GEN4 Mazda 3 cat back exhaust is made from fully polished, mandrel bent, 304 stainless steel. This offers a fantastic look and smooth flow, with corrosion resistance to stand up to the test of time. Every exhaust is fully TIG welded and for further strength, each hanger location has extra reinforcement to keep your exhaust secure. The CorkSport CBE also comes with all the hardware and gaskets you need to make your installation a breeze!

That about does it for details on the CorkSport Best 2019+ Mazda 3 Cat Back Exhaust! We strongly recommend you check out the video for sound clips, you’re going to love it! Give us a call for any questions and submit a product request at this LINK for any and all products you want us to investigate for future mods for your Mazda!

P.S. Already have the Mazda 3 Axle Back Exhaust and want to upgrade to the full Cat Back Exhaust? Check out the Mazda 3 Mid Pipe Kit to complete your exhaust system!

P.P.S.S Have a turbo model and want to know if the exhaust fits? Good news! The CS CBE does fit but, we have a larger cat back exhaust designed specifically for turbo models, to ensure plenty of exhaust flow for future power upgrades!

Connect with us

You may also like

- Axle Back Exhaust for 2019+ Mazda 3 & CX-30!

- The New & Bigger 80mm Mazda 3 Cat Back Exhaust by CorkSport Performance

- The Wait is Over for the 2021+ Mazda Turbo Downpipe

- 5 Reason You Need The Cold Air Box Intake System for the 2019+ Mazda 3 Non-Turbo