Sometimes projects take a lot longer than expected to get to release. After several design changes, lots of simulations, and plenty of mounting revisions, we are happy to announce the release the CorkSport Oil Catch Can for Mazda and Mazdaspeed vehicles.

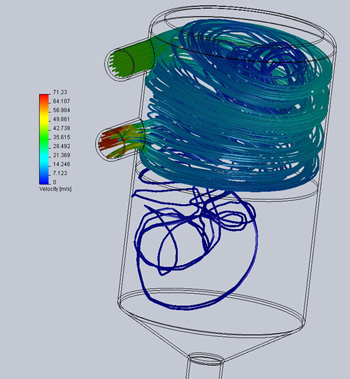

Oil catch cans are designed to separate the water, oil and other contaminants from your PCV system. The PCV system feeds directly in the intake manifold causing all these contaminants to be pushed to the back of the valves then into the engine cylinders. As cars wear, we see more and more contaminants in the PCV system and then into the engine.

Many of you have followed the development as we moved through our design revisions beginning with our first concept, a titanium oil catch can that used stainless steel wool to separate out the oil and several versions in-between before we came to the design that we are happy to be releasing today.

After 3000 miles we performed our first oil change. The results were exactly what we expected, a much smaller concentration of water but a noticeable amount of oil. MZR engines are notorious for slight amounts of blow by getting back into the engine.

The CorkSport Oil Catch Can will enhance the reliability of your engine and improve performance and fuel economy. It is made from high-grade aluminum with a pressed annodized top cap and includes a chemical resistant sight tube. It comes with a complete mounting kit and can be purchased from CorkSport here.

For more information about this product or to purchase one today, please visit our product page on our online catalog at https://corksport.com