CorkSport is pleased to announce the release of the CorkSport Front Lower Arm Brace for the Mazdaspeed 3 and Mazda 3.

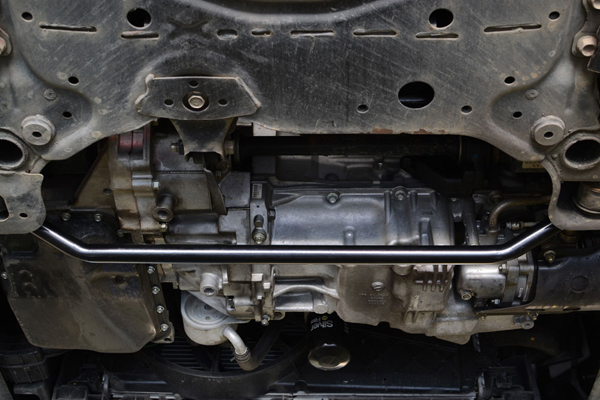

The latest addition in a comprehensive line of suspension products designed by CorkSport to strengthen the weak points in the Mazdaspeed 3 OEM underbody design, the CorkSport Front Lower Arm Brace strengthens chassis rigidity and minimizes flex by tying the lower control arms together.

Designed to fit seamlessly with the OEM control arms, this easy to install suspension component will provide improved steering control and help to maintain the alignment of the vehicle.

The CorkSport Lower Arm Brace has a stainless steel tubular design and CNC machined ends that will help to maintain a lightweight frame while adding structural rigidity. It has been powder coated for added durability and a long-lasting finish, even in extreme weather conditions.

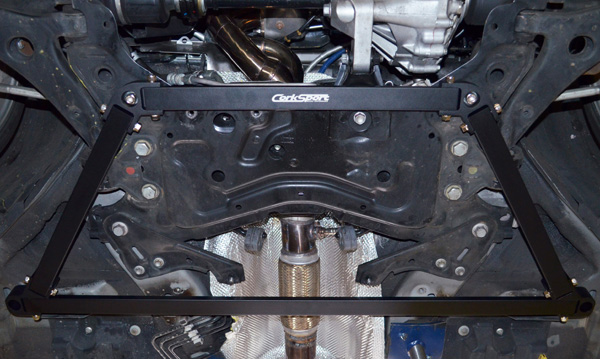

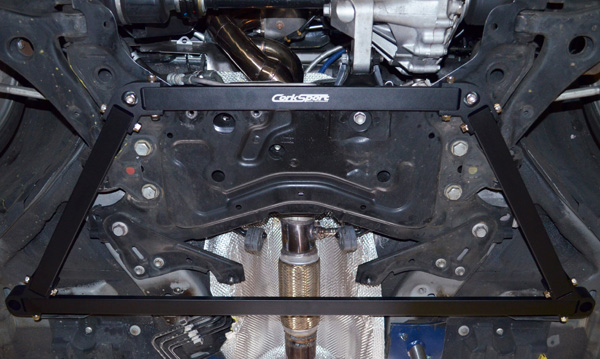

This latest release comes on the heels of another product release by CorkSport also designed to reduce undesirable chassis flex, the CorkSport Mazda 3 and Mazdaspeed 3 Underbody 4-Bar Brace Set. This suspension enhancement links the frame to the sub-frame locking the sub-frame in place for increased control under hard cornering and acceleration.

Immediately after I installed the CorkSport Mazdaspeed 3 Underbody Four Bar Set, I felt a difference in handling and responsiveness, said CorkSport customer, Matt Kellogg, I saw an improvement in cornering and lap times on the track as a result of adding this product to the undercarriage of my Mazdaspeed 3. This is a great addition whether you use your Mazdaspeed 3 as your daily driver or for the track

The CorkSport Lower Arm Brace and CorkSport Underbody Four Bar Set are available for purchase along with a number of other suspension enhancement products at https://www.corksport.com.

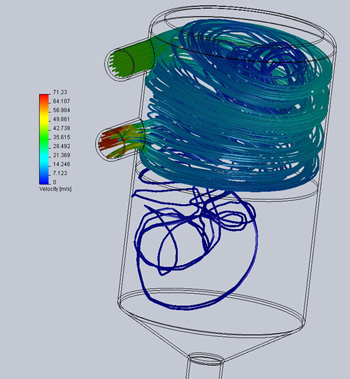

Unlike other catch cans on the market that simply expect the contaminates to fall out of the PCV vapors, our newly released oil catch can has a unique cyclonic vacuum design that forces contaminants to the walls of the can before the air can move back into the intake system. This Solidworks simulation shows how the system was designed. You can see that the air swirls around the outside of the can trapping the contaminants at the wall. This allows them to fall through a disk that is welded between two chambers used to separate the PCV vapors and the contaminants. Once the contaminants are separated you can view them with a sight tube located on the side of the catch can.

Unlike other catch cans on the market that simply expect the contaminates to fall out of the PCV vapors, our newly released oil catch can has a unique cyclonic vacuum design that forces contaminants to the walls of the can before the air can move back into the intake system. This Solidworks simulation shows how the system was designed. You can see that the air swirls around the outside of the can trapping the contaminants at the wall. This allows them to fall through a disk that is welded between two chambers used to separate the PCV vapors and the contaminants. Once the contaminants are separated you can view them with a sight tube located on the side of the catch can. We were particularly surprised to see how much water vapor builds up in the crank case of these cars. After a few miles of driving with the catch can on our shop Mazdaspeed 3, we could really see what separates our catch can from the competition. After only 500 miles we had separated out a great deal of contaminants from the PCV system. Most of which was water vapor that had been trapped in the PCV lines and engine block. This alone should ensure that oil doesn’t break down quickly on our DISI MZR engine.

We were particularly surprised to see how much water vapor builds up in the crank case of these cars. After a few miles of driving with the catch can on our shop Mazdaspeed 3, we could really see what separates our catch can from the competition. After only 500 miles we had separated out a great deal of contaminants from the PCV system. Most of which was water vapor that had been trapped in the PCV lines and engine block. This alone should ensure that oil doesn’t break down quickly on our DISI MZR engine. As you can see from the picture this is something you don’t want getting back into your engine. We took this sample and sent it out for particulate analysis. The results really prove that you don’t want this in your engine. Along with a large amount of oil, which can be seen, there was metal and water present in the oil. All of which we don’t want to be reburned in our engine or stuck to the back of our valves.

As you can see from the picture this is something you don’t want getting back into your engine. We took this sample and sent it out for particulate analysis. The results really prove that you don’t want this in your engine. Along with a large amount of oil, which can be seen, there was metal and water present in the oil. All of which we don’t want to be reburned in our engine or stuck to the back of our valves. Even though it took a little longer than we expected to release this, I’m sure everyone will agree that there are certain things you want done right and somethings are worth the wait. When it comes down to it there are just some contaminants that you never want entering your motor. Most of them are listed on the sheet to the right.

Even though it took a little longer than we expected to release this, I’m sure everyone will agree that there are certain things you want done right and somethings are worth the wait. When it comes down to it there are just some contaminants that you never want entering your motor. Most of them are listed on the sheet to the right.