All CorkSport products go through an extensive process to ensure they are the best fitting, looking and performing parts that they can be. As a product development engineer, I see all of these steps on a day-to-day basis, but we don’t often talk about how an idea evolves into a CorkSport part. Sit back and read on as I give you a glimpse of what goes on during CorkSport R&D.

Concept and Planning

All parts start out as an idea. They come from many sources: employees, forums, car shows. One of our biggest sources of ideas is YOU! Check out the blog on submitting product ideas for more info on how our customers give us their thoughts.

At the beginning of each quarter, all product ideas are evaluated to determine which are feasible and which are going to be pursued moving forward. After the extensive list is narrowed down, they go into a more in-depth evaluation.

This includes defining the scope of the project, how many man hours it is expected to take, evaluating all expected costs of production, and setting a retail price. Without this evaluation, we would encounter all sorts of roadblocks along the way that would delay getting parts out to you all. If everything is looking good, the project is approved and moves forward.

R&D Begins

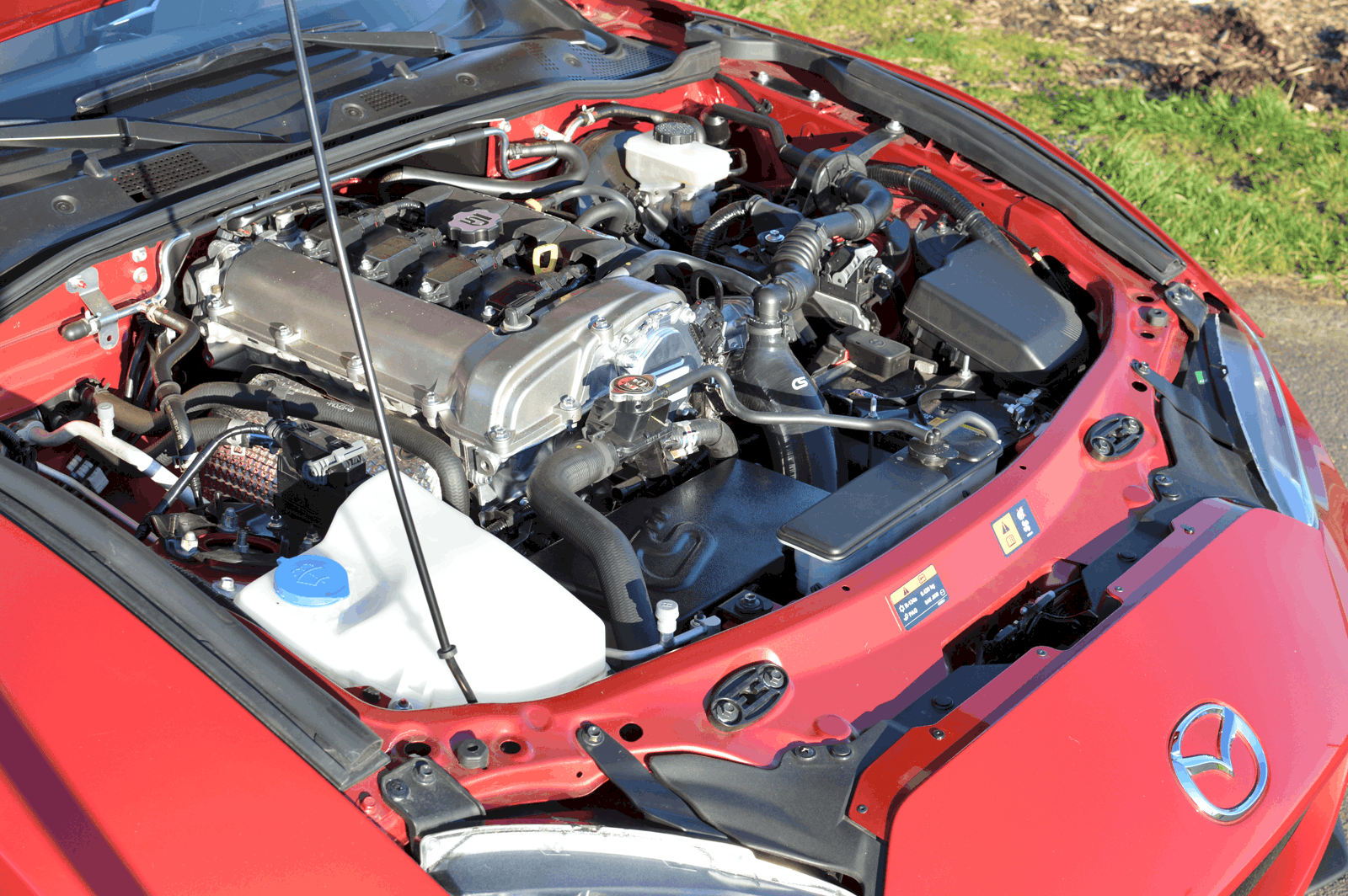

At this stage, it’s time to get our hands dirty (literally in some cases). First, we investigate the car the part is for and the scope of the project to understand exactly what the goal of the part is. Doing this allows us to find all design constraints and look for things we may not be expecting. Replacement part diagrams and factory service manuals can be vital here, especially if we do not have a Mazda or Mazdaspeed readily accessible.

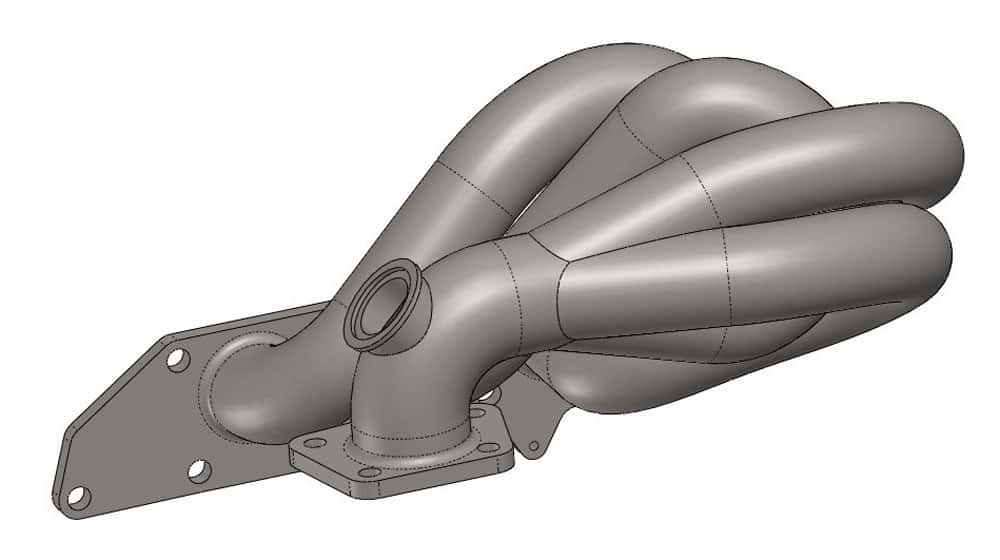

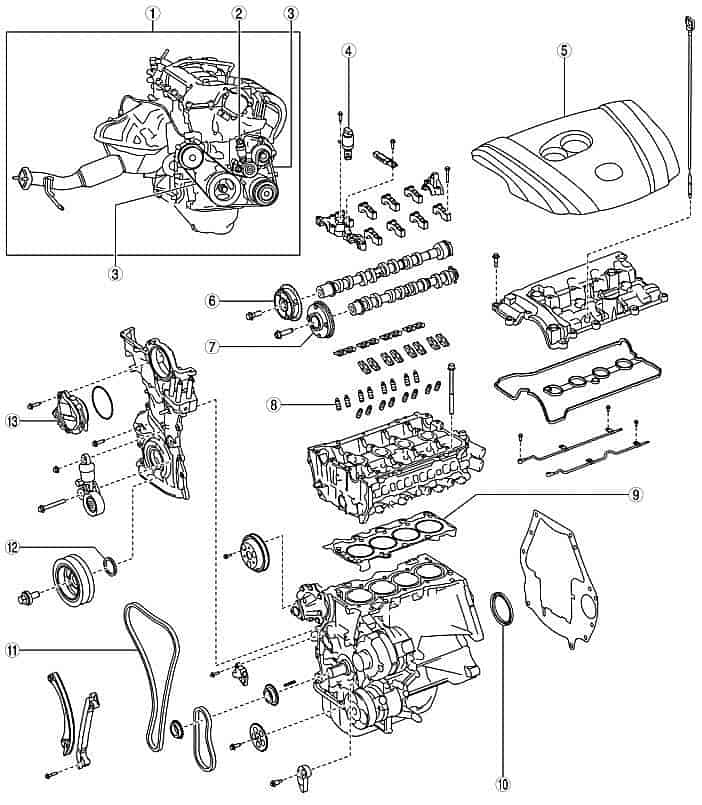

By now we usually have a good idea of what features we want the part to have and can move forward with creating an “MVP”. A minimum viable product is just what it sounds like. Not necessarily pretty or optimized yet but good enough to get to see if an idea will work and to check fitment. During MVP creation we have to consider all design constraints, desired features, integration with other CS parts, and even how to manufacture the part. Check out the changes below from an early MVP to the final design for our GEN3 TMM.

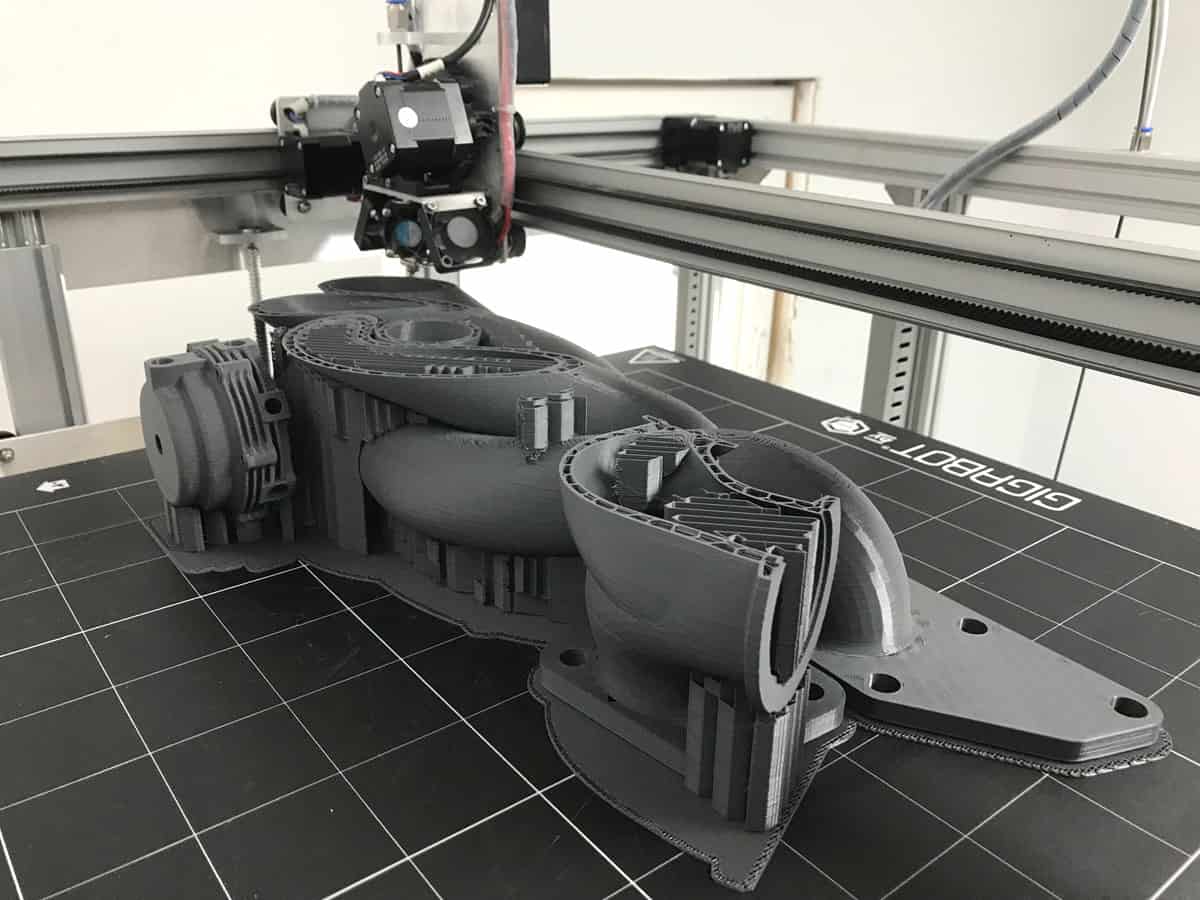

If the part can be 3D printed, we print the initial MVP and test fit. Test fits are by far the most unpredictable part of the whole process as sometimes we discover an issue that can change an entire design. Depending on the part, we can have one test fit and be good to go or four and still have work to do. Once we have revised the MVP to a point where it fits well, looks good, and can be manufactured relatively easily, a functional prototype is produced.

Functional Prototypes

This is where the fun really begins; test fitting is a 3D print is one thing, having the part made out of metal is a whole new story. Depending on the part, we sometimes have to skip directly to this stage as it cannot be easily printed in-house. We always have to be careful doing so to limit the number of expensive prototypes we have made. Sometimes this goes well, other times not so much… This swaybar prototype was limiting suspension travel.

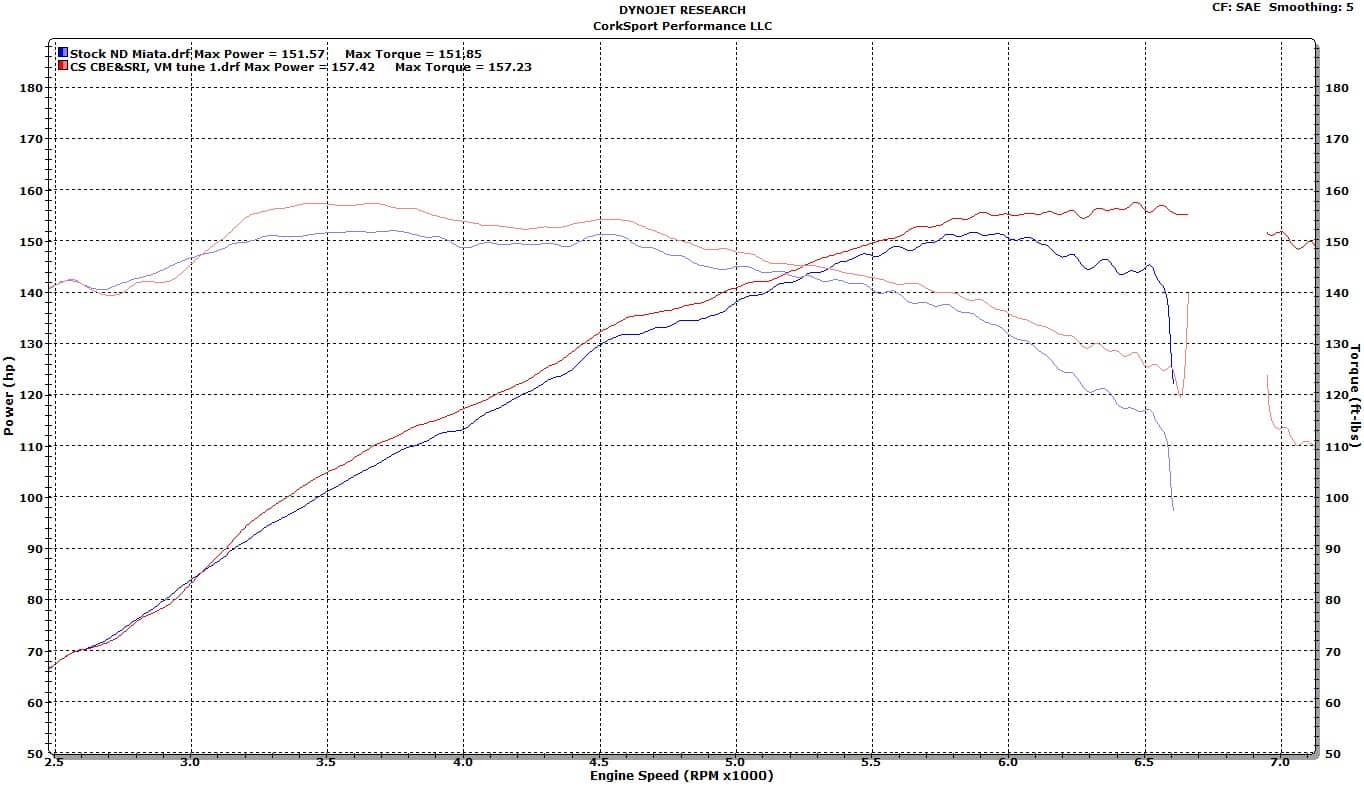

A functional prototype also allows for any testing that we may do. Whether it be on the dyno, track, or on the street, all CorkSport parts are used and abused to ensure they hold up to what you can throw at them. Check out an early CS Throttle Body getting tested on a flow bench.

If we are happy with a prototype, this is where you all can get involved again. We often use “Beta Testers” to get another opinion on the part and to see if they come across any issues. From here we sometimes have revisions that need to be made and another prototype produced but ideally, we are ready to move on.

Manufacture & Prep for Release

From here we move to getting the parts made. Sometimes this is a process that only takes a few weeks, other times it takes many months to complete. The manufacturing method, type of part, and order quantity play a big role here. Additionally, some products have a lot of different parts to make up a whole CS product, so each individual part takes time. Sometimes, we even get to see something unexpected, like these Command Wheel Covers before getting anodized black.

While all of this is going on, we are also preparing the product for release. That way, when our manufactured parts show up, we are ready to send them out to all of you. Installation instructions are created, QA checks are set up, laser etch files are set up, product images and video are taken, the web page listing is set up, and so on. Any and all of the content you see on a product is all created in-house. Engineering school definitely did not prepare me for shooting high-quality photos and video!

Check out a “behind the scenes” look at one of our videos:

At this point, we are pretty much ready to bring the new CorkSport Mazda or Mazdaspeed part out to you all. Throughout this process, we are constantly thinking about the experience someone has when they buy the part to ensure it is something that we would be proud to have on our own cars. After all, we build our dream cars using CS parts just like you do!

-Daniel