Can you believe it’s already August of 2021? It’s crazy how this year has flown by! Between the engineering projects at CorkSport and the racing with @halfmilespeed3…the weeks have become a blurr. BUT sometimes you just have to put your foot down and go racing. That’s what I want to tell you about.

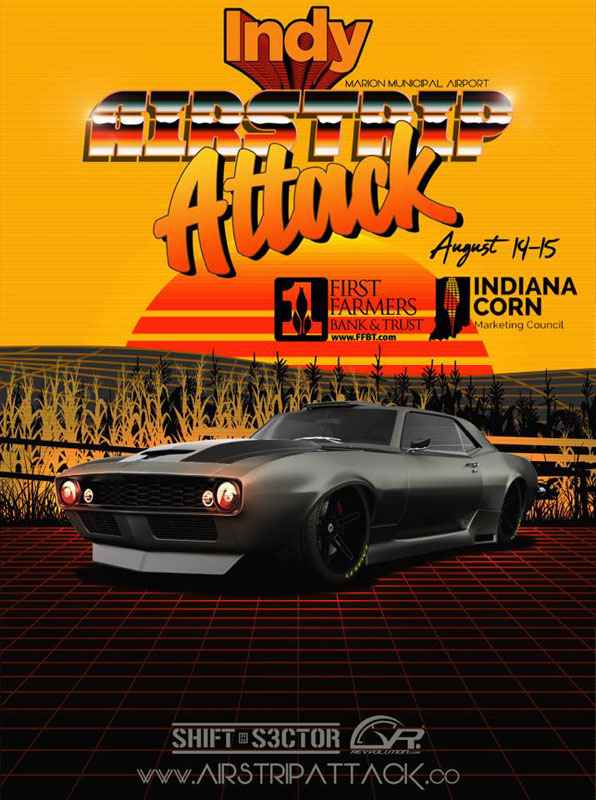

Barett here, Driver of Halfmilespeed 3, where my goal is to race a 2009 Mazdaspeed 3 in the standing half mile. Much like the quarter-mile drag racing you have most likely seen or even participated in, but we stretch the race an extra ¼ mile and we race on no-prep airstrips. The added ¼ mile helps us reach speeds of 150+ up to 250mph for the crazy 2500whp builds. I’d like to invite you to see what’s happened with my 09’ Speed 3 over the last few months and what we hope to achieve at Shift Sector Indy this coming weekend (August 14th – 15th).

Let’s jump back to April 2021; the first race of the season at Coalinga CA. Like all the half-mile races I am participating in, this race was hosted by Shift Sector. If you want to check out Shift Sector more or see if they race you check it out here.

Anyways, the lesson learned was “Don’t change a bunch of shit on your car before the race”. I realize that’s extremely difficult it seems but trust me.

We nuked 3rd and 4th gear in my transmission Saturday AM because we thought it was a great idea to change the shifter assembly and cables a few days before the race. Those take time to get set up correctly or you can do damage…obviously. So, we found a used transmission locally (albeit a GEN 1 trans which is not ideal gearing) and got to work. By 330am (Sunday AM) we had the car running again and back in the trailer…off to the track by 8 am that morning.

Long story short, the car did drive off the trailer but then had an electrical issue that never let the car run again that day. The event was a bust…we eventually figured out the electrical issue was bad ground that was caused by the midnight transmission swap. Lesson learned!

The next event was a Roll Race hosted by Shift Sector down south at Willow Springs Raceway. I was excited to do my first roll race because we all know these cars are not great from a dig, but from a roll, they can really kick some ass.

If you haven’t done a legit (non-Mexico) roll race and get the chance…do it! It was an awesome experience and will be doing many more in the future. With that being said the race was held on the front straight of Big Willow Racetrack…so that meant we were lining up and launching at the exit of the last corner…that was interesting to say the least. The morning was four hours of practice and testing. The car was doing great, but the heat was really starting to wear on me and the car. By the end of practice, I was starting to see the heat really build up with 180+ degF intake temps and boost air temps in the 140+ degF range.

We let the car sit for almost a couple hours before the actual competition started. This helped alot, but damn was it still hot outside with ambient air temps over 100 degF. When my race came along I lined up with a 335i with a big single turbo and hood exit exhaust…we set off with a target hit speed of 40-50mph. Luckily this was right in the sweet spot for 3rd gear and just a bit of brake boosting to hit the launch hard. As we got to the finish line the light flashed and we went for it….but the heat said nope.

Unfortunately my car stumbled and cut power. I went a bit to aggressive on the brake boosting and super-heated my boost air temps. This caused the ECU to pull power for a split second…just enough for the BMW to pull ahead.

Despite this I pushed forward and was reeling him in but there just wasn’t enough straight to catch him.

Video Link if Possible: “Built with Barett Episode 3”

Another lesson learned…I need to get my cooling in check before the next event. That next event is Shift Sector Indy. This is a standing half mile drag race at Marion Municipal Airport in Marion Indiana.

Image: shift-sector-indy-2021

As I write this, my Speed is sitting in a transport truck operated by English Racing along with nine other cars going to the same event. Quoting Myles Kerr @ English Racing…”4 GTR’s, 2 damn Honda’s, a Mazda, NSX, 570 and a 720.”

Yup, the Mazda is riding with the big boys. If I could take a guess, those two big rigs are holding upwards of 15,000+ whp of racecar…HOLY SHIT. I think my humble little Mazda is the only car not making 4 digit power…

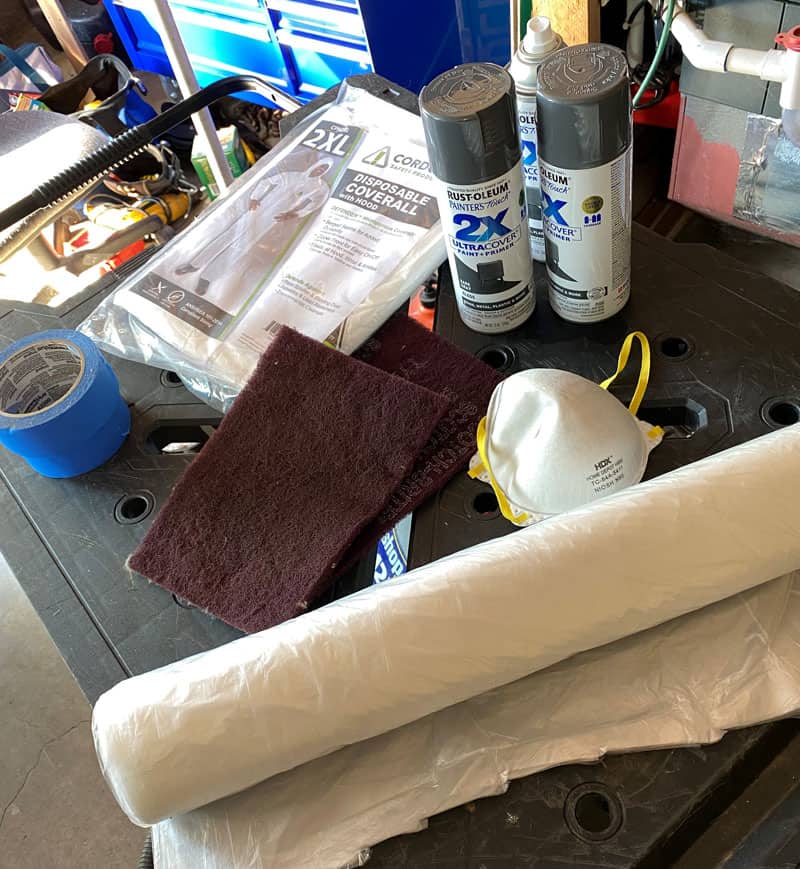

Anyways, we made some changes for the Indy race for power, traction, heat control and reliability.

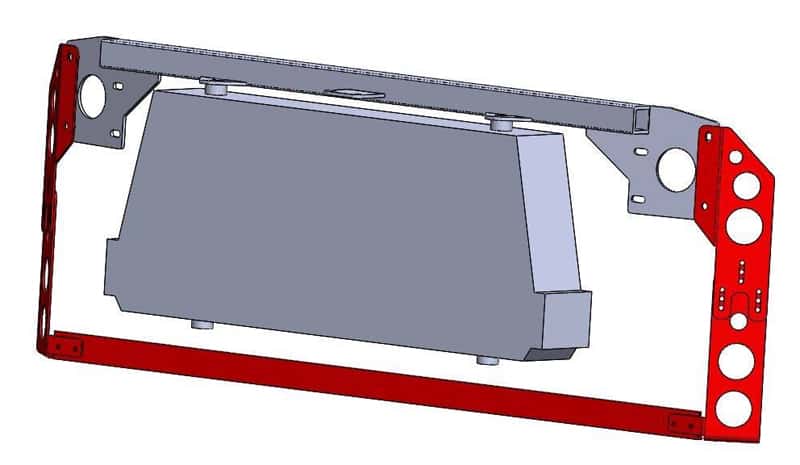

Heat killed us last time so let’s resolve that with a hole in the headlight (haha yes I said that) and force CO2 cooling on the intercooler.

So, to solve the high intake air temperature issue I cut a big ol’ hole in my headlight. Now I have a direct source of ambient air hitting the air intake system. Unfortunately, the CO2 cooling system did not arrive in time to get installed so let’s just hope it’s not so damn hot in Indiana.

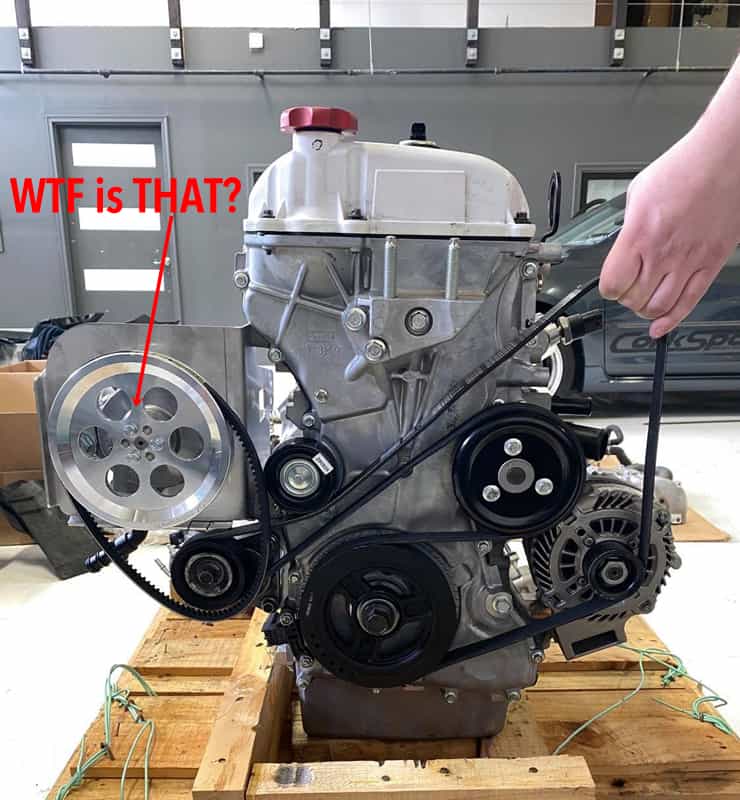

For power and traction, I have finally moved from the restrictive stock ECU to the amazing Motec M142 ECU. With help from some awesome friends, I was able to get the Motec installed and running most of my desired auxiliary sensors (coolant pressure, oil pressure, PI fuel rain pressure, eMAP, EGT). There are two major benefits of Motec over the stock ECU (right now).

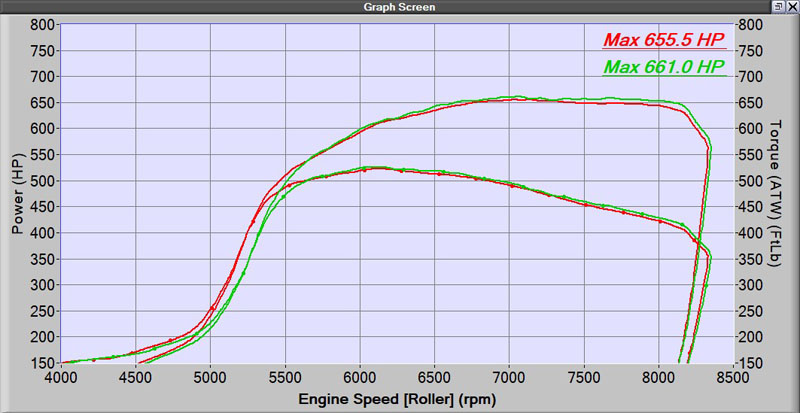

First, the Motec allows proper tuning control to 10k+ engine RPM whereas the stock ECU in the GEN1 flat lines control at 7k RPM. While the car/engine can rev out past 7k, the ECU stops actively controlling the tuning, and therefore power falls off. The new power band for the halfmilespeed3 carries to 8500rpm thanks to Motec and Justin @ Freektune!

Video Link if Possible: “Built with Barett Episode 4”

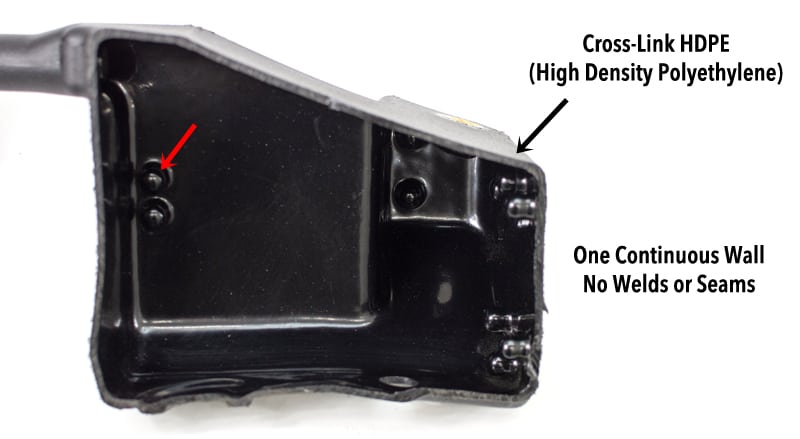

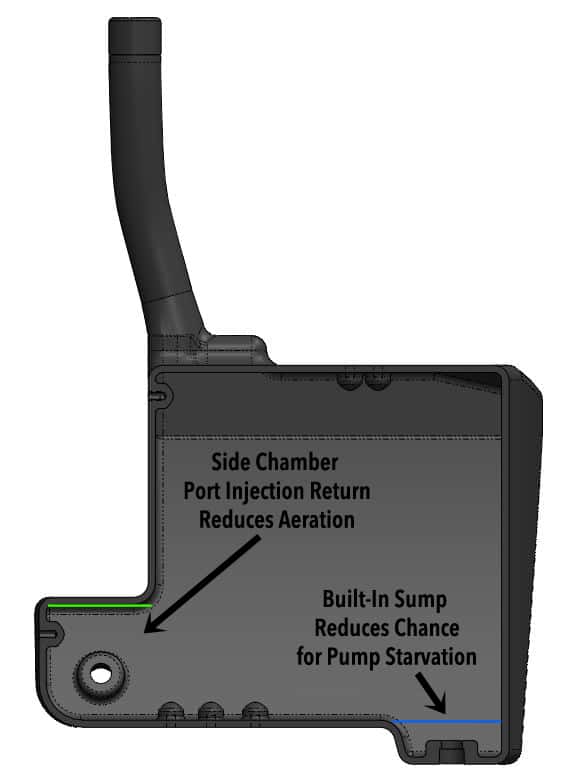

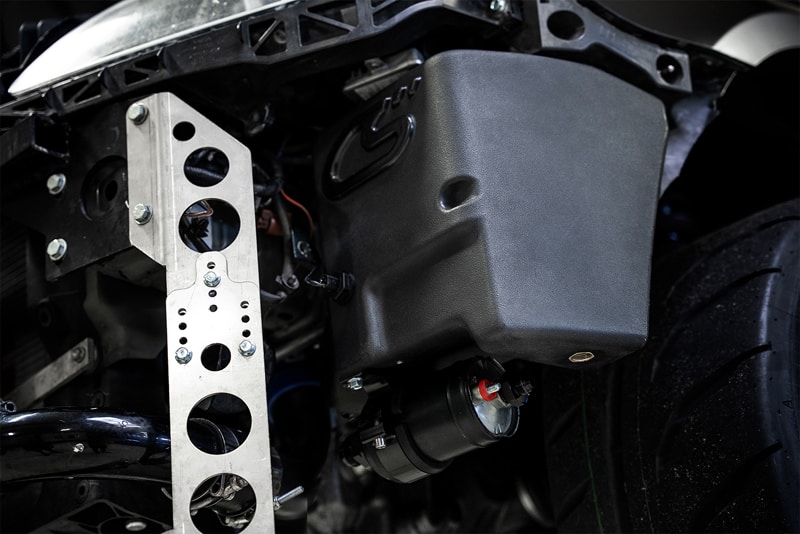

Just so you are aware, the engine is a complete CorkSport catalog build featuring an Overspeed Built Block (for 1000hp) with CorkSport manifolds, 4” intake, 3.5” exhaust, port injection fuel system and Kelford D camshafts. The turbocharger is still a stock flange CorkSport CST6.

So with that wish me luck and I hope to see you at the airstrip. Get out and drive your car…you don’t have to have a bonkers build and power number to compete and enjoy your Mazdaspeed. Go get a number and send it down a runway!

Image: how-to-race-your-mazdaspeed

Thanks for checking out the latest update with @halfmilespeed3. Follow on Instagram for more updates and checkout the live link for the Shift Sector Indy event in my bio.

- Barett @ CS