We here at CorkSport are proud to announce the relaunch of the Mazda 3 Rear Motor Mount.

Yes, you read that correct, this is a re-launch. At CorkSport we push ourselves to design and develop new and interesting products every day, with that, we try new and innovative manufacturing designs and methods in an attempt to create exceptional, competitive, cost-effective products for our loyal customers.

Sometimes those new and innovative manufacturing methods end up not being as awesome as we originally expected. This is just part of the designing and learning process. Let’s get into the details.

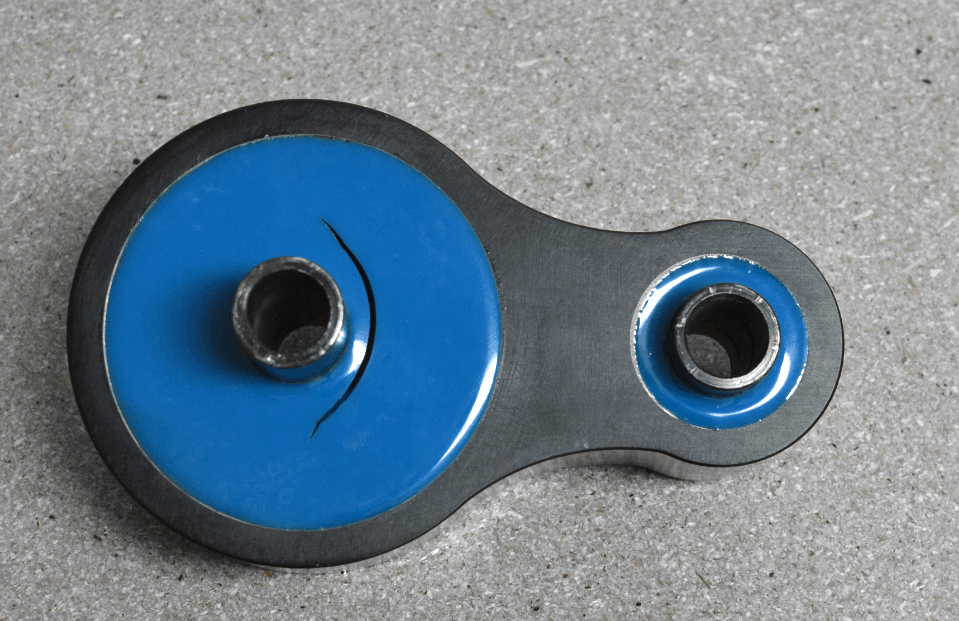

The original, let’s call it V1, Mazda3 RMM used a new-to-us manufacturing method of applying the polyurethane to the billet aluminum body called vulcanizing. The billet aluminum body and the steel sleeves are mounted in a fixture then liquid polyurethane was poured into the assembly and cooled until the polyurethane had set to the final hardness. This process appeared to be very promising; each part was set up identically, it was nearly impossible to have any missing parts not sent to you, and most importantly the polyurethane was adhered to the billet aluminum body and therefore could not fall out. More on that last bit later.

We moved forward with the manufacturing method and had a few samples made with various polyurethane durometers ranging from 60A to 80A. After various testing, we determined that 70A was the best compromise of response and NVH (Noise, Vibration, Harshness) experienced by the driver. We continued testing for a few months to verify long-term durability and found no issues. Hooray! We moved forward with production to get this new great Mazda6 RMM out the door to you.

Unfortunately, it appears that our testing period just wasn’t quite long enough. Eventually, the polyurethane would fail but fail in a style we had never experienced before. Long story short, polyurethane has excellent compression strength compared to the tensile strength. The polyurethane was being pulled/split apart due to the forces of the engine.

Now we had a few options of how to redesign the Mazda 6 Rear Motor Mount after going through the failure analysis.

- We could have simply stuck with the same design and just increased the stiffness of the polyurethane. Increasing the durometer rating of the poly increases the tensile strength, but this would have resulted in an unsatisfactory driving experience for you which was unacceptable.

- The other option was to start from scratch again to create a new design that did not compromise the driving experience or the durability; with challenge comes innovation.

Again we went through many different designs, with the greatest challenge coming in the form of retaining the polyurethane pucks. Typically the polyurethane pucks are retained by whatever the mount is bolting to, but with the Mazda motor mount, the steel sleeves extend far past the outer edge of the polyurethane pucks. This leaves the pucks free to slide out of the billet aluminum body and cause a major failure.

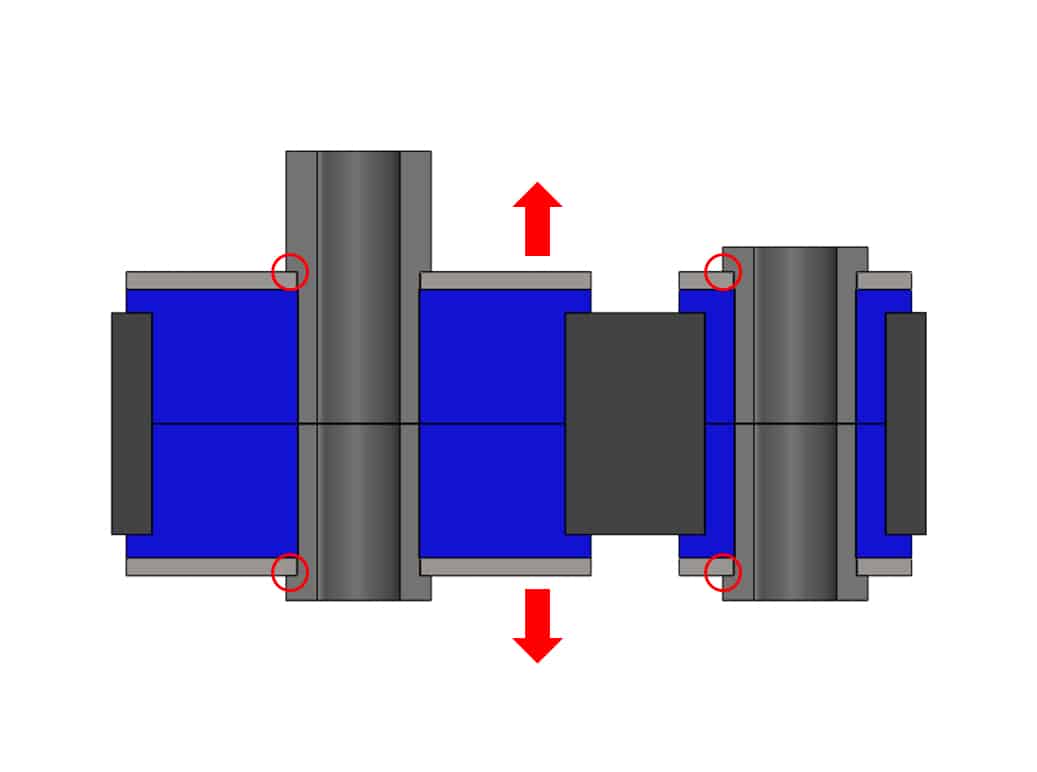

Using the conventional polyurethane puck style, we developed a design that would work, but more than doubled the number of parts needed which increased the chance for something to go wrong and drives up the cost. This design is shown below:

The red arrows show the direction the conventional polyurethane puck would slide out of the body. The red circles show the puck retention system to hold the washer and pucks in the body. This retention design required many parts to be successful.

With the cost going through the roof we had to go back to the drawing board. There had to be a better way… and there was.

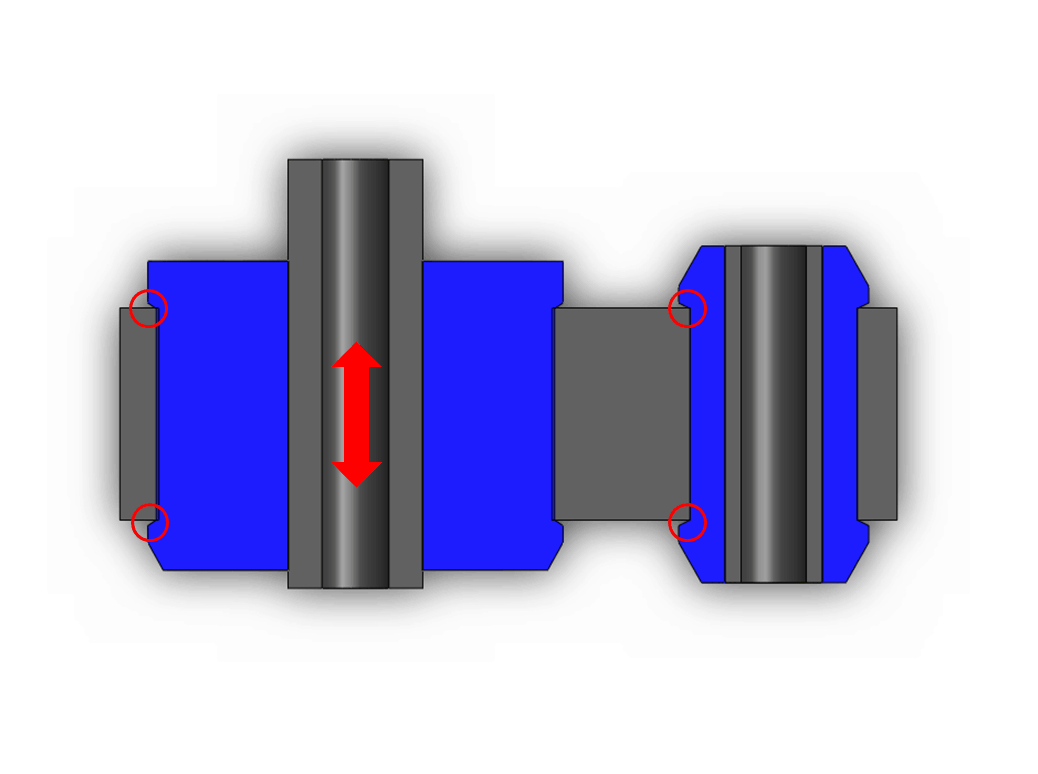

The third major iteration shown above solved the problems of the V2 design and got us away from the vulcanized polyurethane of the V1 design. Things were looking good. With the V3 design, the polyurethane pucks are pressed into the billet aluminum body. The pucks have ribs, shown with the red circles that are just large enough to keep the puck in place, but small enough to let the puck be pressed into the body.

With this, we were able to make some clever designs to the RMM to keep it centered in the engine and chassis brackets on the vehicle. The smaller diameter puck extends out to the ends of the steel sleeves; this keeps the entire rear motor mount centered. The large diameter puck retains itself in the body and allows the associated steel sleeve free to slide for easy installation; shown with the red arrows.

Now… does it work? YES! Pretty fantastically, we might add!

We have had this design on a handful of vehicles, one of those being the CorkSport Mazda 3 Racecar during the SCCA Run-Offs at Indianapolis Speedway. Other than some dirt and grime, the tested RMM looks great.

You were probably expecting this blog to be all about the details and reasons you should buy this performance RMM for your Mazda 3, Mazda 6, or CX-5. All those details can be found on our website, and I invite you to check them out.

What we really want to get across here is this:

First and foremost, we will always do the best we can to take care of you and your car if there is ever an issue or concern with your CorkSport part.

Second, if you are a driving enthusiast, if you go driving for the sake of just driving, then you need this RMM in your life. It will completely change and improve your driving experience, plain and simple.

-Barett, CS Engineering