If you have a 2014 + Mazda 6 then today is your lucky day! CorkSport is officially releasing the 2014+ Mazda 6 Rear Sway Bar, LED Light Kit, and License Plate Relocation Kit.

Relocate Your Plate

In order to improve airflow, and look better we created the 2014+ Mazda 6 License Plate Relocation Kit. The stock location of the license plate blocks the airflow through the grill of your Mazda 6 which is why we relocated the License Plate to the Tow Hook adapter location. This kit is simple to install and really creates a stunning front view of your Mazda 6.

The CorkSport 2014+ License Plate Bracket Relocation Kit is available at our online catalog. For more information please visit our product listing at: https://corksport.com/corksport-license-plate-bracket-relocation-kit-for-2014-mazda-6.html

Lights, Camera, Action

Allow your new Mazda 6 to shine, literally. Replacing the yellowish lighting inside the cabin of your Mazda 6 is one of the simplest upgrades to your car and makes the cabin more visible, cleaner looking, and feel higher-end. Don’t let the yellow light of the Mazda 6 ruin the atmosphere or limit the clean look of the interior, instead swap out the bulbs for fresh white LED lights.

The CorkSport 2014+ LED Light Kit is available at our online catalog for only $59.99 and is ready to ship now. For more information please visit our product listing at: https://corksport.com/corksport-led-light-kit-for-2014-mazda-6.html

Own the Corners

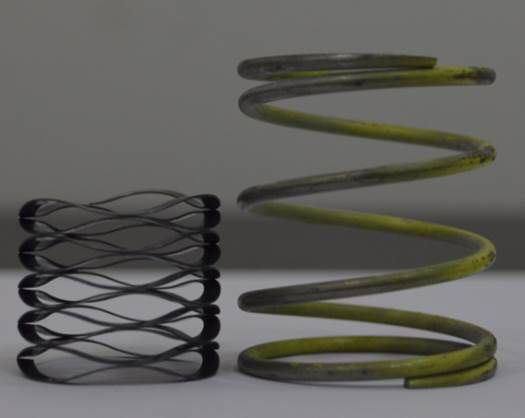

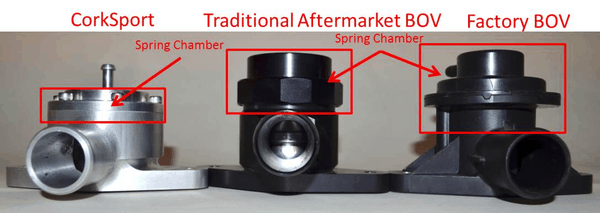

If you want to handle better, then this is the upgrade for you. Adding the 2014+ Mazda 6 Rear Sway Bar will limit the body roll when cornering by helping transfer some of the inside compression to the outside suspension. The rear sway bar effectively increases the compressed springs rate by helping distribute the load more evenly across the rear suspension. This helps control body roll and ultimately helps you corner flatter, faster and with more predictability.

The CorkSport 2014+ Mazda 6 Rear Sway Bar is available at our online catalog for only $229.99 and is ready to ship now. For more information please visit our product listing at: https://corksport.com/corksport-2014-mazda-6-rear-sway-bar.html

We also have the CorkSport 2013+ CX5 Rear Sway Bar available here: https://corksport.com/corksport-2013-mazda-cx5-rear-sway-bar.html

Upcoming Products:

CorkSport has been hard at work at more than just the parts listed above, soon we will be releasing the CorkSport 2014 Mazda 6 Power Series Short Ram Intake. Just like all our intakes this has been tested in varying conditions for proven power gains and improved sound.

If you can’t wait to improve the sound of your 2014 Mazda 6, we also have an exhaust for the Mazda 6 that will be released soon. It sounds great and looks even better. CorkSport has a great opportunity for one lucky person. If you simply HAVE to HAVE the Mazda 6 Axle Back Exhaust before anyone else then send Spencer an email (Update: we have already filled the beta testing spot.). We are looking for one lucky 2014 Mazda 6 owner to Beta test our CorkSport Axle Back exhaust and give us their thoughts. If chosen you will get to be inside the testing process and work with our engineers to provide feedback about our newest part!

https://www.youtube.com/watch?v=Edu2KOE3tOA

Stay tuned for official release dates and more exciting news in the near future!

Also, if you haven’t signed up for our Email Newsletter, now would be a great time. This is where we release coupons, news, release dates, events, and more.