“Which intercooler should I get?” At Corksport, we get this question almost every day. The debate of top mount intercooler vs. front mount intercooler has been one that has raged on in the forums for years. Just looking around you will see both options on all sorts of cars. So what is the answer?

The Mazdaspeed 3 and Mazdaspeed 6 both come with a top mount intercooler (TMIC) from the factory. There are many reasons for this, but the main one is that it is much cheaper to manufacture and install. A top-mounted intercooler can be installed directly into the engine at the factory so it is ready to drop into the car, saving both time and money.

Pros of the TMIC

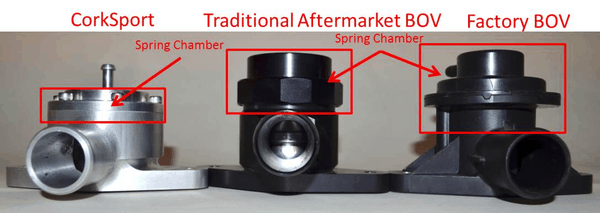

The upside of the TMIC is that it uses the shortest possible path from the turbo to the engine. This reduces the amount of time it takes for the car to accelerate, this feeling can be amplified between shifts when the power comes back on very quickly. The TMIC is also very simple and compact, with very few connections and possible places for air leaks. A TMIC will also weigh very little compared to a FMIC setup and usually is in a place with very good airflow. With our TMIC, it’s a simple replacement as it fits like OEM. Generally, it is more affordable than an FMIC. So, if you’re on a budget, the TMIC may be what you want.

Cons of the TMIC

The downside of TMICs is that they are generally limited in size by the design of the car. Often times they are much smaller than most FMICs. They are typically placed very high in the engine bay, raising the car’s center of gravity. Most importantly, the biggest downside of the TMIC is that it sits in a hot engine bay. Just by sitting on top of the motor, the TMIC can soak up heat, thereby decreasing its effectiveness in cooling the air compressed by your turbo.

Pros of an FMIC

The principles are mostly the same for the pros and cons of the FMIC. The core of an FMIC can be much larger and, in the case of a properly designed system, can cool temperatures much more effectively. Being placed further away from the engine and out into the stream of air of your car can make the FMIC much cooler and, more importantly, more consistent. One last reason that many people love FMIC’s is the look, nothing says I mean business more than a massive bar and plate core smiling in your rear view.

Cons of an FMIC

The biggest downside of an FMIC is that the installation process is much longer, requiring your car to be out while you do the work. Another downside of an FMIC can be the much longer piping needed to route compressed air to them. This piping can increase turbo lag and usually has many couplers that may cause the potential for air leaks or other issues.

So what does CorkSport say? As a general rule, we would say that if you don’t plan to add more than 50-100 horsepower, a top mount intercooler will work just fine and be much easier on your plans and wallet. If you eventually want to go wild with your car and build it up much higher than stock, you will want to seriously consider a front mount intercooler. Our advice would be to try to plan in advance what you want out of the car so that you only have to buy parts once.

Happy spooling!

Connect with us