CorkSport Max Flow Fuel Pump Internals

Todays the day, CorkSport is releasing the High Pressure Fuel Pump system to the public. The demand is high, people have been asking us for weeks when these are coming. To get yours, click here and order yours today. They will be shipped first in first out so get in line soon to get yours.

In case you missed our 5 part blog series here are some great points.

PART 1 – (Go to Part 1)

“… Most aftermarket fuel pump upgrades consist of changing the internal parts of the factory pump with an enlarged piston and sleeve. By enlarging the piston, you increase the volume of the pump; thus creating more flow and the ability to maintain pressure at higher power levels.

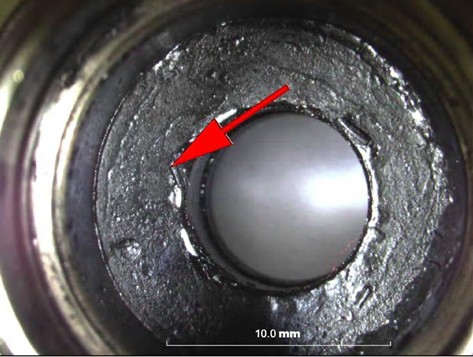

When you first start taking the fuel pump apart, the first thing you are met with is the sight of a strange black deposit in the cap of the pump. Shown above are the deposits common to most caps. The bottom is a machined surface that should be clear of debris. In order for us to more clearly understand the situation we sent the cap out to undergo chemical analysis.”

Go to Part 1 for more …

Part 2 – (Go to Part 2)

“Does size matter? When looking at the stock piston on the factory fuel pump you can sure say that it does matter. If you increase the piston diameter you increase the flow of the pump. We have decided to compare the similar internals first and then compare the APR pump afterwards.”

Go to Part 2 for more …

Part 3 – (Go to Part 3)

“Now that we have a good understanding of the basics for these high pressure fuel pumps we can start to really dig deeper into the specifications. One of the items we were really curious about were the materials used in the construction of these pumps. We decided to have the hardness tested and ascertain the materials used. The factory pump internals do not use any coating, the hardness test showed us that the internals went through a hardening process as the core was significantly softer than the surface. Because of these hardness requirements, many other aftermarket internals use a coating of some sort to decrease friction between the piston and the sleeve. As for what the stock internals are made from, we answered that. Except for the hardening procedure, according to their chemical breakdown, they match a common die steel, so nothing too fancy.”

Go to Part 3 for more …

Part 4 – (Go to Part 4)

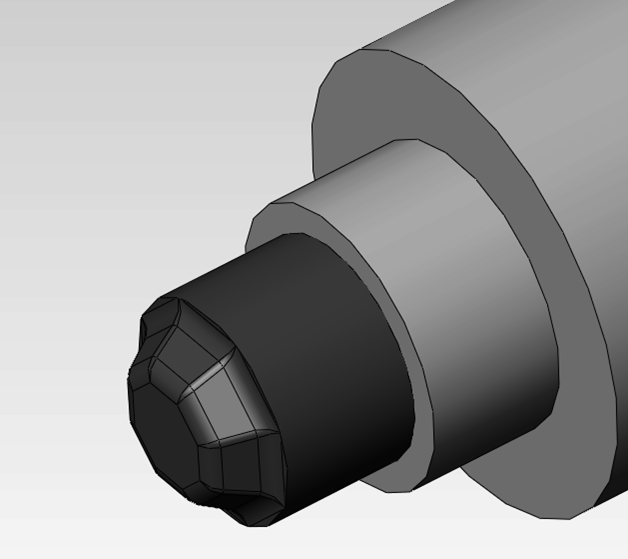

“ … We then built all the internals available in SolidWorks and tested the efficiency of them all for flow design and volume. This was merely the beginning of our design phase but helped us realize many great ideas (as well as a few not so great ones). We ended up with a design unlike any other on the market that, according to the data, would be more efficient than anything on the market.”

Go to Part 4 for more …

Part 5 – (Go to Part 5)

“After choosing a very strong alloy for our internals, we then machine their tolerances to an incredible 6 microns! To make sure the tolerances are paired for life, we serialize the parts to prevent any issues and to track the life of the pumps. We then surface treat the pumps to achieve the alloys maximum strength; only after the maximum hardness is achieved do we apply our surface treatments to bring the overall durability to an even higher level”

Go to Part 5 for more …