Good day all of my CorkSport followers. Is anyone else excited for warm weather, and track days? Now is the time to get that Mazdaspeed prepped, modded, and out to the track.

The CorkSport team has plenty of experience when it comes to track days. We have noticed in the past year more and more people have been getting into a Mazdaspeed platform, and before too long they are modding the car to test its capabilities. Derrick is our road course guy in his 2015 Mazda 3, and I am the guy that likes the 1320. So what do you need to be able to run at the track? Protecting yourself, and making sure the car is properly put together can affect if you will be able to run your Mazdaspeed down the 1320.

Clothing

You will not be able to race your Mazdaspeed unless you wear pants, and closed toe shoes. Every track you go to will require you to wear these two things. Every little bit counts especially if you have a high horsepower Mazdaspeed. We have all seen the videos of accidents happening. I would hate to roll my Mazdaspeed, break glass, and have glass bits hitting my legs. So don’t forget those pants, and yoga pants do not count to all of you lady drivers.

Helmet

Each track has standard rules when it comes to safety equipment. Depending on how fast your Mazdaspeed runs will determine what safety equipment you will need in order to race. 13.99 and faster you will need to make sure and wear a helmet. Also, if you run 13.99 and faster, you will not be able to have a passenger in the car with you. If it is your first time at the track and you run faster than a 13.99 without a helmet, the track officials will ask you to wear a helmet moving forward. Failure to comply could get you removed from the track.

Vehicle Maintenance

This is probably the most important part of the inspection process when going to the track. If you have been racing when oil/coolant dumps onto the track then you know how long it can take to get that stuff cleaned up. Here are a few things the officials look for when you are trying to race your Mazdaspeed.

-

CorkSport Battery Box is mounted correctly with a battery tie down

-

Nothing else loose in the engine bay like my CorkSport Electronic Boost Control Solenoid

-

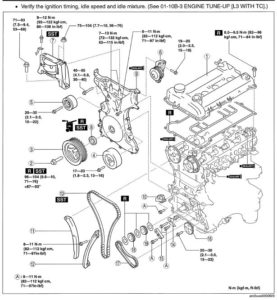

Make sure no coolant or oil is leaking from the engine bay. So be careful with our CorkSport Oil Temp/Pressure Gauge when installing it with the CorkSport Sandwich Plate.

-

Good tires

-

Working seat belts

-

They will also make you turn on your headlights when the sun goes down

These things are non-negotiable. If your Mazdaspeed does not pass any of these then the track officials will not let you run your car down the track. All you fast guys out there need to double check with your local track to see what you have to do to the car depending on how fast you run.

Additional Safety Equipment

If you do have a Mazdaspeed capable of 11’s or faster, then you will be required to do a lot more to the car in order to safely run. I would double check with your local track, but every track I have been to require you to have a roll cage, and a fire suit if you are running 11’s or faster in the 1320. Also, if you have your battery relocated into the hatch, you will need a kill switch mounted somewhere on the rear of the car just in case you roll when racing.

READERS BEWARE:

Going to the track is highly addicting. CorkSport will not be responsible for empty wallets in an attempt to make your Mazdaspeed go faster. CorkSport will also not be held responsible for pulled muscles in your cheeks from having too much fun. However, if you must modify your Mazdaspeed, CorkSport will be there to help you reach your goals! Stay safe, and ZOOM ZOOM people.

Cheers,

Luke