We know by now that adding power to your Mazda is fairly straightforward up to a certain point. However, sooner or later, that hunger for power means you’re going to need to step up to a new fuel pump that can flow more fuel. By seeing that most of the fuel pumps on the market were largely the same, we decided to see what kind of innovations we could bring to the table. At this point we had learned volumes about the pumps on the market through our research and decided to engineer a new set of pump internals that focused on everything that we had learned.

We know this is possibly the worst kept secret since Area 51, but we started engineering fuel pump internals over 2 years ago and we aim to show you why ours is worth the wait.

We didn’t just set out to make another pump; the market has plenty of those. We set out to make the best Mazda fuel pump upgrade on the market specifically for Mazdas from a company that ONLY makes parts for Mazdas.

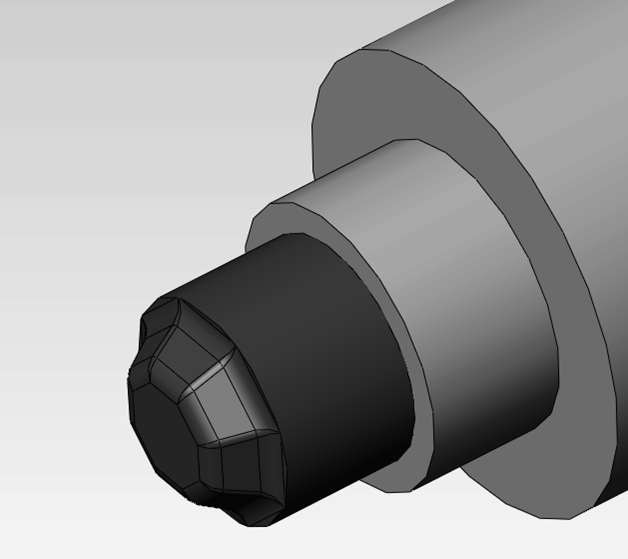

We started by researching many different technologies and engineering ideas in the pressure ranges experienced in these fuel pumps. We purchased every kit on the market and a brand new replacement from Mazda to test. The results from some of those tests can be found here (Link to blogs 1,2, and 3). After agreeing that 9.8mm was the maximum size we could attempt for the piston without making the sleeve wall too thin, we could start engineering the rest of the part.

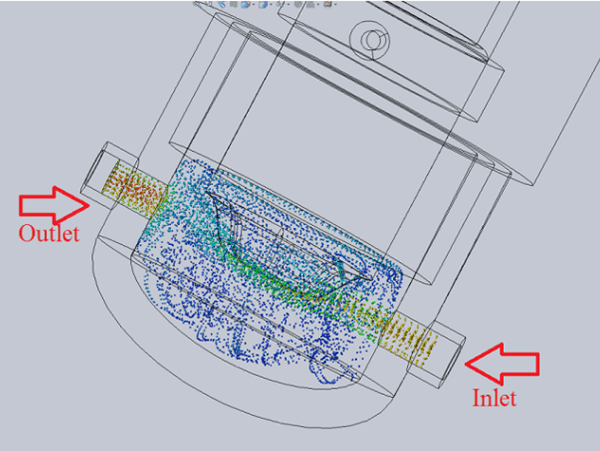

We then built all the internals available in SolidWorks and tested the efficiency of them all for flow design and volume. This was merely the beginning of our design phase but helped us realize many great ideas (as well as a few not so great ones). We ended up with a design unlike any other on the market that, according to the data, would be more efficient than anything on the market.

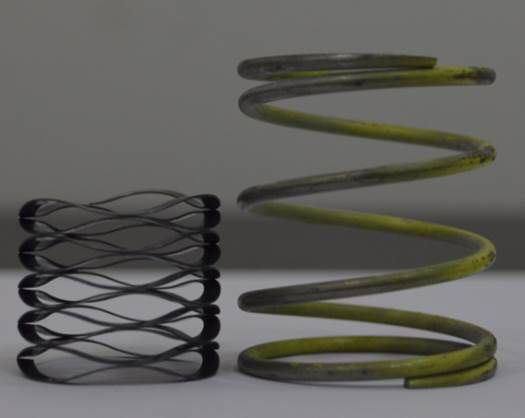

With the increase in flow and efficiency we knew that our design could also benefit from a stiffer spring rate for the pump. That would enable higher RPM’s and improved cam wear over the life of the pump. Since we would be flowing more, the pressure on the pump would be greater than ever, the stiffer spring was just good insurance to get the power we needed even past the stock redline.

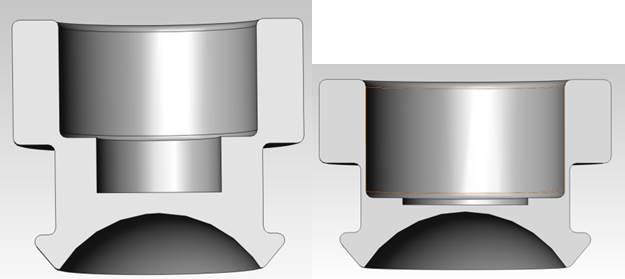

During our testing we also discovered the keeper assembly used by the factory is no accident. Many of the other pumps on the market use a keeper system similar to an intake or exhaust valve. This style does a fantastic job of locking the piston in place, but creates a few issues of its own. Because of the flow of fuel, the piston rides one side of the sleeve more than the other; over time, this will wear more into the piston which will affect clearances and efficiency. To prevent this, the factory style keeper allows the piston to spin as the spring moves up and down. That led us to choose the factory style retainer. We didn’t want to guess on either design without proof of our theory so we produced samples of both styles to prove wear differences and address installation challenges related to both styles.

Now that the cat is out of the bag, we’ll have just one more fuel pump blog next week with a very exciting limited offer. Stay tuned as CorkSport is about to take Mazda performance one step higher!