At CorkSport we’ve had a lot of questions over the years about mass airflow (MAF) signals. Including some great discussions about a pesky measurement called grams per second (g/s) and what that really means. There is a lot of interesting misinformation out there that we have heard and wanted to take the time to explain how grams per second actually work and what it really translates to. To understand what grams per second really is, we will first discuss where the reading comes from.

When you are logging a MAF signal you have a few options. One is MAF voltage and one is MAF signal. They are really the same thing, just expressed in different ways. The MAF sensor itself is a 5-volt system that gets a signal from the air traveling in the MAF housing. A typical MAF sensor uses a wire or film that is heated electrically. The incoming air cools the element to which the sensor has to regulate; this regulation lets the ECU know how much air is going through the engine. This voltage is then converted in a table stored in the ECU (Engine Control Unit) and this is where you get your g/s reading.

Now for the fun part: when you purchase an aftermarket short ram intake the MAF housing shape and diameter determine the voltage reading and thus the g/s reading. If the housing has been engineered correctly then the reading should be fairly close to the factory reading. Often the factory runs cars on the rich side for fueling when they are in open loop. The sizing of the MAF can be adjusted to create more power at the top of the rev range by leaning out the air/fuel mixture. The MAF signal also is a major part of calculating load values which control timing and most other functions of the engine. This is not a part that should be taken lightly or changed indiscriminately. In our extensive testing we have found that even half a millimeter in diameter of a MAF can cause measureable differences.

The g/s reading can also be used to check power-increasing mods such as exhaust or intercoolers. If you log power runs you can see the g/s increase with different mods. Although, be careful when comparing data on the same car. If you aren’t testing on the same day or conditions you can see slight differences because of air density or other environmental conditions. Unfortunately, when you want to compare different intakes you will not be able to show an apples-to-apples comparison. Because the MAF housings are not the same sizes between brands the signal will be different. If you check a MAF housing that is larger than stock you will read less g/s and one that is smaller you will read more g/s. Simply put, when comparing different intakes or any other factors that are different: Grams per Second does not equal power.

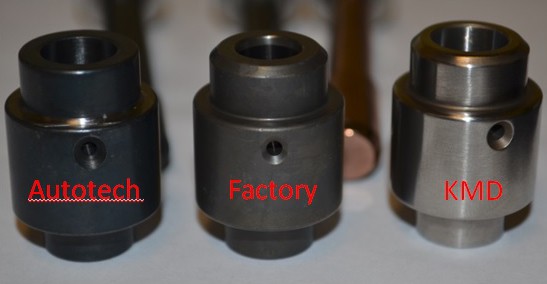

With all the complications in making a MAF to perform exactly how you want, we chose a one-piece fully machined aluminum MAF housing. This way you can precisely control quality and sizing. Then by creating an air straightener that is injection molded, we can have the most control over our MAF signals. There can often be issues with purchasing lesser quality MAFs housings that are welded together or bolted to pipes. Not only can you have leaks but you cannot preserve the shape perfectly. Look for more intake articles and an explanation of what a big MAF intake is and when you actually need one soon.

You may also like: