Ask any of my friends or coworkers and they will quickly tell you “Barett Loves Curves!”

I’ve always been the first guy to dive into the corner, hit the apex and power out with just a touch of wheel spin. My car follows suit with its build; upgraded sway bars, big brake kit up front and the steering wheel to hold it all together. Of course, my friends were always there with the peer pressure to hit 1320…Luke McCarvel being the biggest offender (check out his “Drag Strip Checklist”). However, one day my opinion changed.

At some point I realized that I can’t knock it until I try it, so I finally succumbed to the straight line life.

So let’s go through the first line up: Do a burnout…that was much easier than I expected.

Ok now roll up to the staging line…don’t be that guy that rolls through and has to back up. Knuckles white on the steering wheel, heart beating in rhythm with the launch control, closely watching the tree light up…GREEN LIGHT! Launch…wheel spin to redline. Shift…wheel spin to redline. Shift…try to modulate the throttle, but still tons of wheel spin. Shift…finally the car hooks, builds speed then it’s over in the blink of an eye.

All that build up waiting in line, doing the burnout, staging, launching and rowing the gears for a few seconds of intense adrenaline. It was an absolute blast; I couldn’t believe how intoxicating just a single pass was. I wanted more and I wanted it immediately. Back in line, I went.

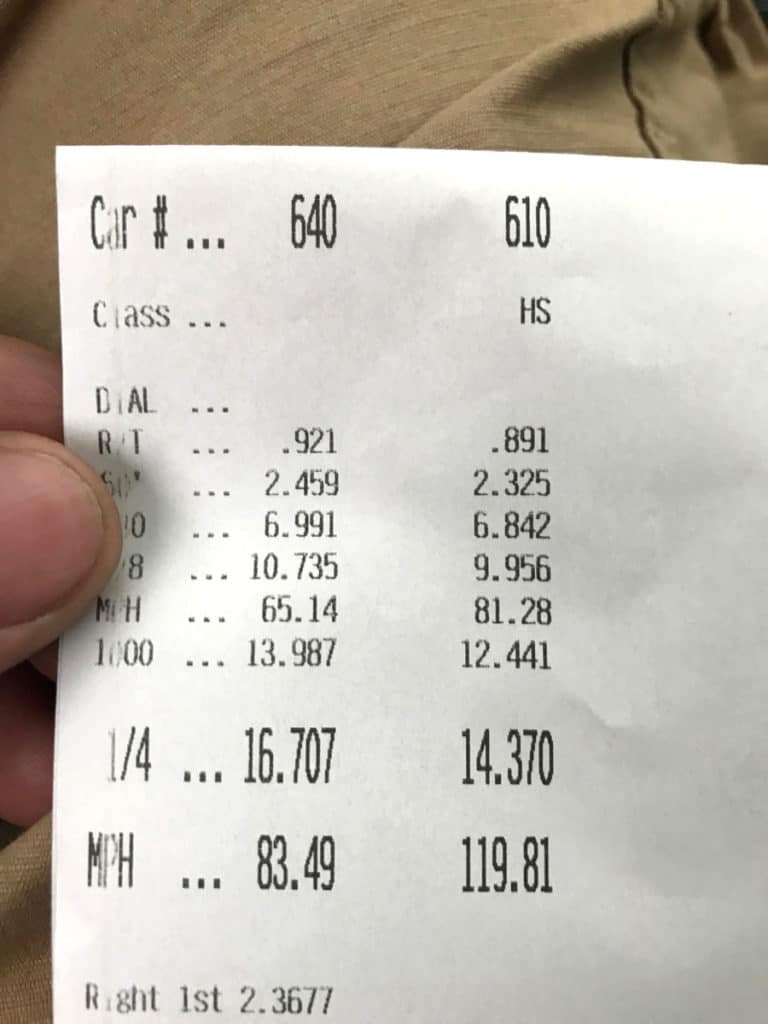

My first pass was an awkward 14.37sec @ 119.8mph. I say awkward because that is a slow ET for the trap speed. It shows just how much tire spin I was fighting and how much time I was giving up because of it. With full interior and street tires this was to be expected, however, the crowd thought it was quite funny either way.

I proceeded to make 3 more passes as the night progressed. Each time making a small change to the car or to my approach and control of the launch and throttle modulation. Each pass rewarded me with a small improvement for my efforts. Each pass down the strip left me wanting more from the next pass.

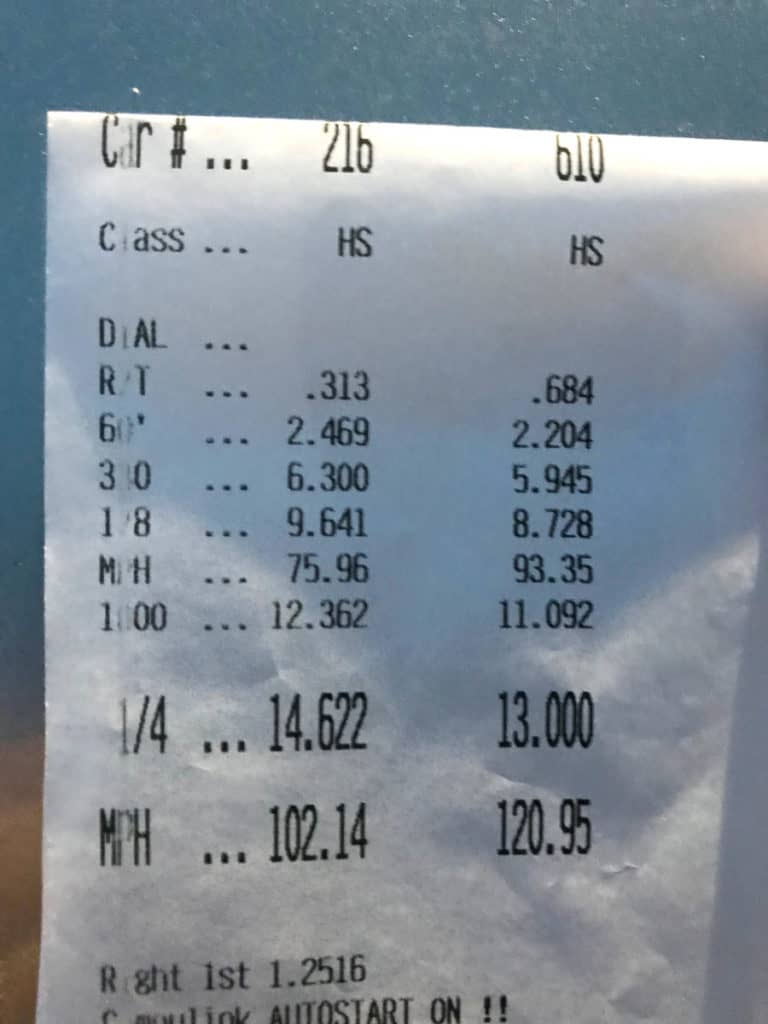

The third pass was the most frustrating of them all. At the start of the night, I set a personal goal to break into the 12s. I didn’t know if it was realistic or a complete dream, but I had to start somewhere. That third pass was also the one that drove me to get my shit together because it teased me with a 13.000sec @ 120.95mph. So Close!

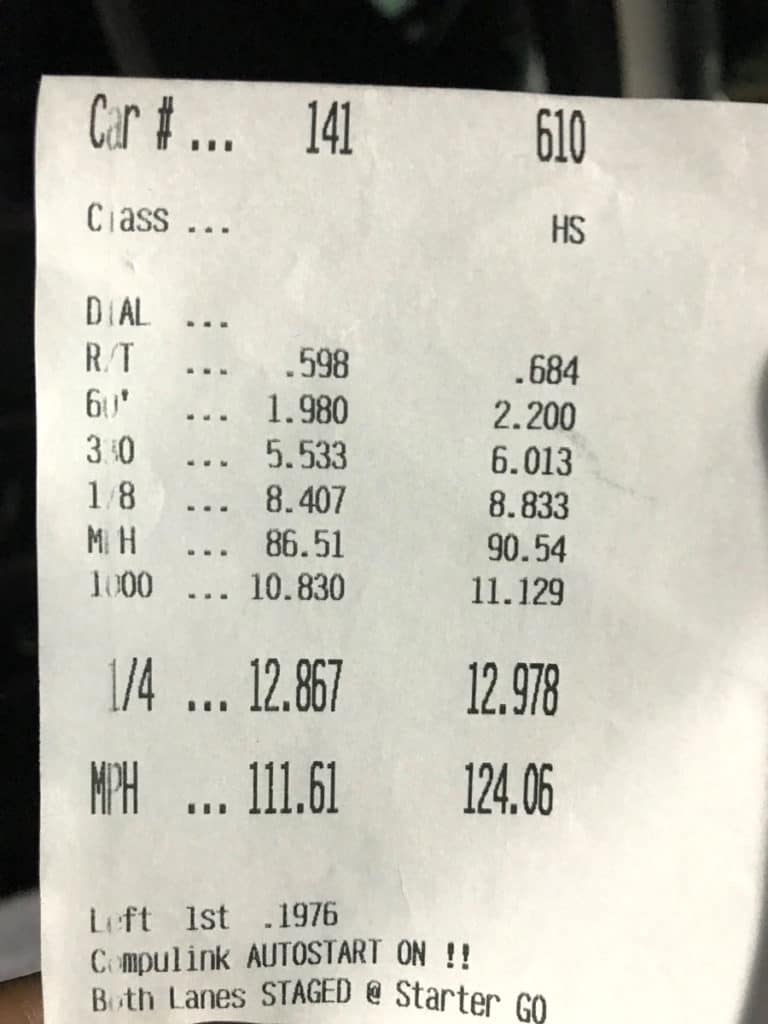

Alright one more pass, this was the one I could feel it. 30 minutes later I’m staring at the burnout box, line up drop 2nd and get the tires nice and hot. Pull up to staging next to a real crowd killer (I mean Mustang).

Yellow… yellow…yellow…….GREEN LIGHT!

Launch…little wheel spin to redline.

Shift…little more wheel spin to redline. Shift…modulate the throttle with only a tiny bit of wheel spin. Shift…now the car really hooks but I’m a few lengths behind that Musta…oh shit there’s the turbo…I’m reeling him in…it’s so close…I fly past him with the rev limiter dancing.

It’s over…deep breath…that was it I know it.

Now the quick jaunt to the end of the strip then back to the little building and the old guy that’s been racing since flatheads were a thing.

“Car 610?”

“Yes Sir”

“Here’s your slip. Is that a Maaazda?”

YES! Hit my goal for the night and the car can still drive me home. I call that a success.

I parked my car, picked up my 120+mph club sticker and enjoyed the rest of the night with my good friends from Idaho Mazda Takeover. It was a great night and one I plan to top in the near future.

Anybody have some stock brakes and drag slicks I can borrow?

-BS @ CS