Roasting the Top Five Car Guy Stereotypes…it’s all about the Mazda Enthusiasts We’ve met…

The friends I want to talk about are your Mazda Event friends. Likely, you know them from your Nator club, Mazda club, or local car community, and truth be told they often fall into pretty great stereotypes of “Car Guy”.

Ready to have some fun…Let’s Roast ‘em!

The Newbie

This Guy is new to the Mazdaspeed/Mazda scene. He doesn’t know a ton about his car, it’s capabilities, and some of us would like to give a couple driving lessons to him first. He has big dreams for his Mazda and has a full wish-list of parts to prove it.

We can’t hate on this guy too much, because we all start somewhere, but the amount of time it takes to get him up to speed on acronyms, lingo, and basic tools isn’t always worth it. You would rather just do the work for him yourself so you can trust it’s done right. He’s a great guy, and will eventually be an awesome full member of the Mazda club, but he has some growing to do…

The Know it all

This Mazda Guy just NEVER SHUTS UP… whether he is right or wrong, he always has something to say and will stick to his opinions regardless of being proved wrong. He’s nice enough to hang out with, but we all avoid having strong opinions with him… it’s a guaranteed disaster.

These Guys end up spinning out of the group or buying a new (non-Mazda) vehicle, either way, they don’t make friends easily, and we often don’t get together and hang out without them on purpose.

The Actually DOES know it all Guy

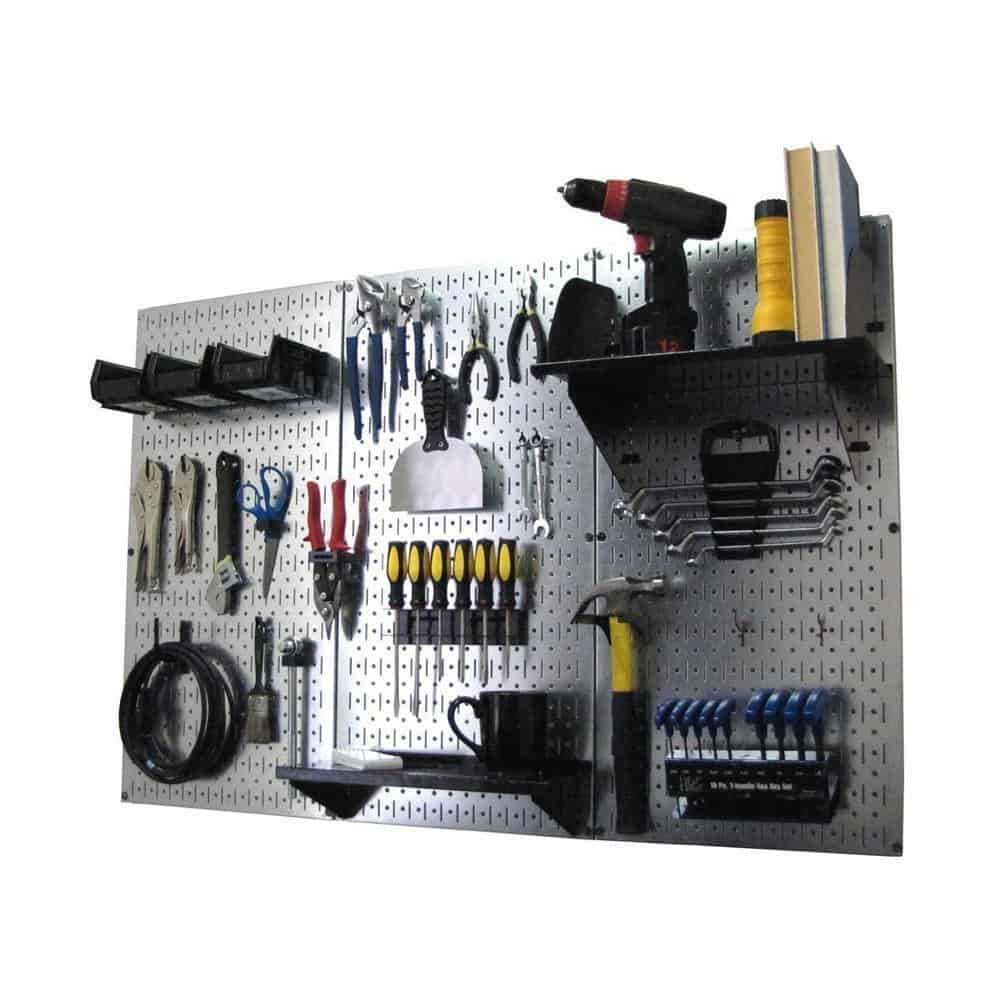

Ironically enough the “Actually does know it all Guy” often speaks the least in the group. Having learned from experience, they set back and watch some people make fools of themselves and others take the hard path to learning. Always there to lend a helping hand when something does go wrong, and offer up advice when it’s requested in a respectful manner, this guy is it a DIY mechanic and has no trouble getting his hands dirty for his friends…

Arguably the best Guy of the stereotypes and genuinely a great resource for the Mazda and Mazdaspeed community. A true influencer and most likely a beta tester.

The Not So Great with People Guy

There is often this guy at car meets. He’s not great with people, especially girls, and even more especially with new people he’s quiet. He’s necessary to the club because he truly does have one of the best rides there are, and it inspires us all to push our capabilities. He can drive the sh*t out of his Mazdaspeed, is seemingly fearless when it comes to speed and handling, and is always willing to talk like a savant when it comes to his build, driving style, and dream car plans.

Talk cars or parts and you’ve got this guys attention, try to talk about anything else and you can see the glaze come over his eyes as he takes another drink from his beverage of choice…and dreams about a BIGGER and BETTER MAZDA.

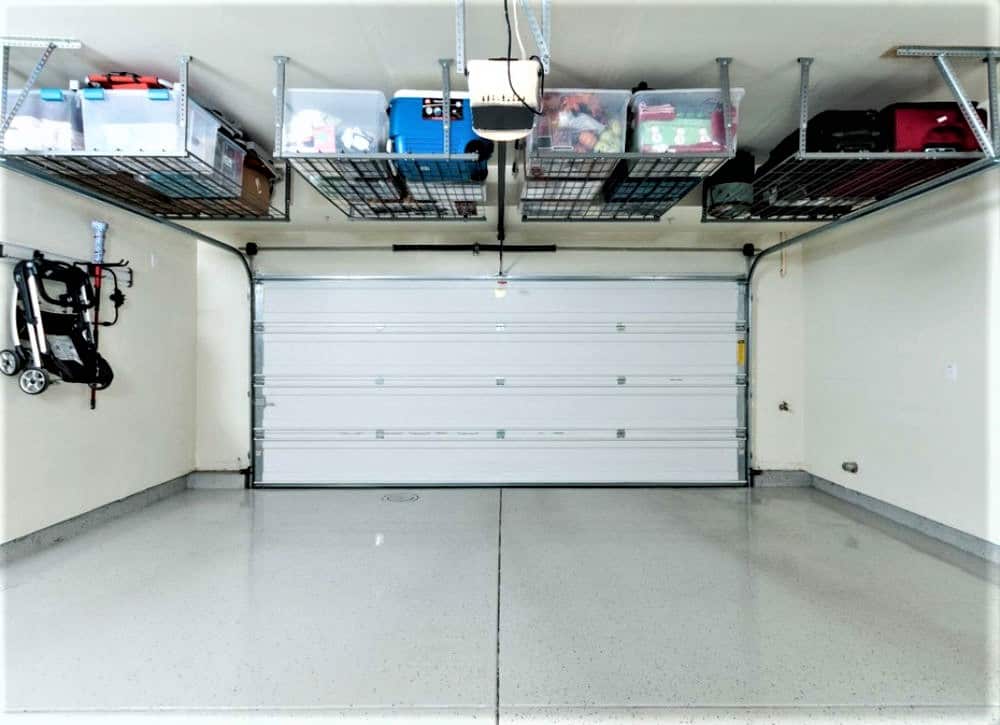

The Guy Who Always Breaks Down

Whether at the track, a long drive, or auto crossing, every time we get together this Guy is going to break something, or completely break down. More often than not it comes down to just plain crappy luck, so we all do our best to pitch in and help him get things fixed before we head out. “Never leave a man behind” means we’re often out at all hours in an abandoned parking lot or garage trying to get him back on the road again!

We wish this guy’s luck would change… especially because we’re always there trying to help fix it…

I know there are plenty of other stereotypical car guys, and heck there are even stereotypes for the Car Girls out there. I cannot wait to see you ROAST your friends in the comments…perhaps without even telling them which type of Guy you’re accusing them of falling under.

Until next time, whichever Guy you are, stay safe, stay happy, and stay fast my friends!

– CorkSport