A few weeks ago, we discussed some of the design intent behind the CST5 turbocharger for the Mazdaspeed platform. Today, we want to follow up with the CST6 Turbo . The CST5 and the CST6 both were a result of CorkSport’s desire to develop a new stock flange turbocharger that goes beyond the power limits of our FANTASTIC CST4 Turbo.

During the development of a higher power stock flange performance turbo, we found that we were asking too much of the CST4 Design. The result of our efforts is the CST5 Turbo which you can see here and the CST6 Turbo which we are about to dig into.

In this blog, we’ll dig into the wheel sizing, the CHRA, and some of the challenges we faced in the development and testing stages for the CST6.

Stay Up-to-date with CorkSport

Compressor Wheel

The compressor wheel utilized on the CST6 is well-known and trusted, GEN1 GTX76. The GTX76 compressor is rated for 64 lb/min and is capable of boost pressures that will require a 4 bar MAP sensor upgrade. Like the CST5, the compressor housing is a 4-inch inlet with anti-surge porting.

Ball Bearing Design for the Mazdaspeed Turbo

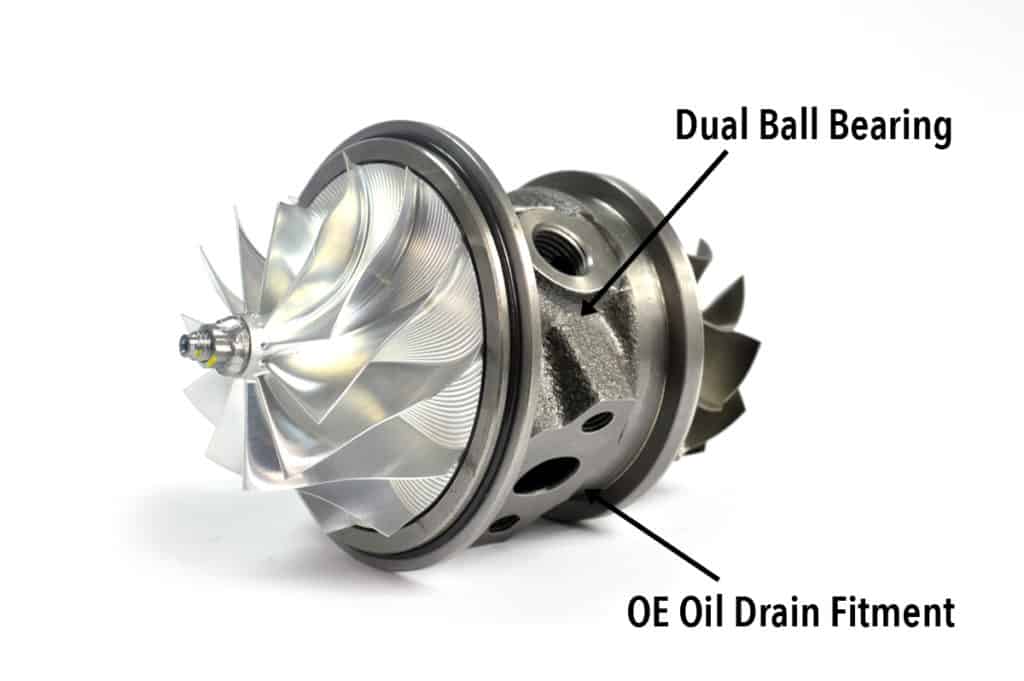

Unlike the CST4 and CST5, the CST6 Mazdaspeed Turbo uses a completely different CHRA and bearing system, and for good reason. As the turbocharger wheel sizes increase, so do the weight and potential boost pressure. This results in higher loads on the wheels, turbine shaft, and bearing system. To increase the durability and performance of the CST6, we opted to move from a conventional journal-bearing design to a more modern and robust ball-bearing design.

The ball bearing system improves durability and stability for high horsepower/high boost operation along with improved spool and transient response. Changing the CHRA did pose some new challenges, however. Ease of installation has always been a key feature with CorkSport products and that’s not lost with the CST6. The CHRA has been modified to support the use of the OE oil drain line and all necessary oil feed components and coolant components are included for seamless installation.

Turbo Compressor Wheel

Like the CST5 Turbo, we’ve put a focus on the wheel size ratio and have validated its performance. The CST6 Performance Turbo uses the Gen1 GTX76 compressor wheel paired with the Garrett GT35 turbine wheel…aka GTX3576r. This wheel combination provides us with a ratio of 1.12 which falls well within the rule of thumb discussed the in the past CST5 blog.

In testing, we found that increasing the size of the turbine wheel from a GT30 to a GT35 with the same GTX76 compressor wheel resulted in more top-end power and no penalty in spool time. This combo also provided a good power delta from the CST5 to better provide an optimal power option for the community. Since then, the CST6 has proven power at 600+whp at ~34- 35psi, and testing will continue past 40psi.

External Wastegate

The initial testing of the CST6 Mazdaspeed turbo started with an internally wastegated turbine housing as that was the original goal with the CST5 and CST6. However, it quickly became obvious that a turbocharger of this size and power potential could not be safely controlled with an internal wastegate. The amount the wastegate port and “exhaust” or flow was not nearly adequate for proper boost control.

The boost would creep to nearly 26psi with no signs of tapering off. Nevertheless, we continued testing, knowing that auxiliary fueling was necessary. Once the CST6 power and durability were validated, we moved to design a turbine housing that could provide the necessary boost control and power potential.

Above is the removed CST6 internally waste-gated housing. In our

From this discovery and analysis, we developed the EWG turbine housing with the CST6 in mind. The scroll size was increased, the wall thickness was increased in critical areas, and the 44mm EWG port was added.

With the use of the EWG turbine housing, boost control is now spot on and can easily control from spring pressure to an excess of 35+psi. Stick around as we continue to push the limits of the CST6 Mazdaspeed Turbo as we continue testing and validation of the CorkSport V2 Intake Manifold w/Port Injection.

Thanks for tuning in with CorkSport Mazda Performance.

Connect with us:

You may also like

- The CST6 has Arrived!

- 600hp Mazdaspeed 3 Build Path – CorkSport Barett’s 2009 Mazdaspeed

- How to Make A 900 Horsepower Mazdaspeed 3 AWD Swap – CX7 Rear Subframe (Part 3)

- Mazdaslow to Mazdaspeed

Was going to get the bnrs4 but if this is out soon and is better will wait for yours

I was also looking at some options like bnrs5 ,I trust Corksport more with any parts for my Mazda, so yeah CST5 I think would be ideal for my goals