Recently I have been getting questions about bolts and how important they are and why we use the parts we do. Here at CorkSport, the little things matter, we engineer every part to outperform not only the manufacturers specifications but also our customers expectations. When something important like a motor mount or an intake is designed at CorkSport we take great care to think about the little things such as: can we make our MAF housings one piece so there can be no sealing issues or possible failures? Can we use bolts that are as strong or stronger than the factory in every application? These are some of the many things that makes us different. Thinking of the little details can really mean the difference between the success or failure of a part. With that in mind, I wanted to just take a quick minute to discuss bolts.

Most bolts are classified by two very easy systems: Grade and Class.

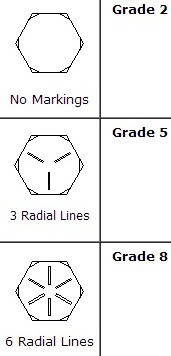

Grade is for Standard (SAE) size bolts and the more common types are grades 2, 5 and 8. The higher the grade, the more that has been done to increase its strength such as quenching and tempering. Graded bolts will typically have radial lines on the face of the bolt to show the grade. No markings mean grade 2, 3 radial lines means grade 5 and 6 radial lines means a grade 8

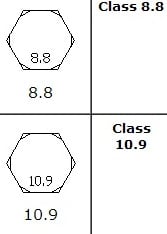

Class is for metric and like many things metric… they’ve made it easy. The most common classes are 8.8 and 10.9. The class of the bolt is right on the face of it. So an 8.8 class bolt will have 8.8 on the face and a 10.9 will have the same.

Because these numbers can be similar it can be easy to confuse them. Many are using 8.8 class bolts in the place of grade 8 bolts not knowing that a grade 8 bolt is over 30% stronger than a class 8.8 bolt. Many may call this nit-picking but here at CorkSport we are obsessed with attention to detail and want to make things right the first time and if for some reason we don’t then we dedicate ourselves to figuring out why and use that knowledge in further development in the future. Thank you for letting CorkSport have a place on your car and in your life, we appreciate it and take that responsibility very seriously.

Cheers,

Joel

The strength of a bolt is extremely important. In my opinion, if someone says its nitpicking… they are not exactly educated in mechanics. Every bolt has a torque spec on a car/truck. The bolt must support the stress of the torque and the stress of any other forces after the toque down. Put one in that can only handle the stress of torqueing down it might pop as soon as every other stress is applied. Bolt types should never be over looked.

I know people complain about CS pricing sometimes, but personally I know I never have to worry about quality, and I know that you all have spent the time engineering the piece to make it the best it can be.

Using quality bolts is one of the most important specs of a quality part but also it is often one of the most overlooked. Thanks for sweating the small stuff guys.