We recently went over the stock intercooler & piping system for the 2018+ Mazda 6 2.5T. If you missed it, be sure to check out the blog HERE.

Today, it’s the first look at the CorkSport parts that will be coming in the near future to remedy the issues we found with the OEM system. We are not covering our upgraded intercooler just yet though; today’s focus is piping upgrades!

As you can see we’ve been busy getting the Mazda 6 upgraded intercooler piping designed & 3D printed for test fitting (while you can’t see it I promise the cold pipe is hanging out in there too!). I’m happy to say there’s plenty of room to fit the upgraded piping sizes that we were targeting and

These horsepower gains typically

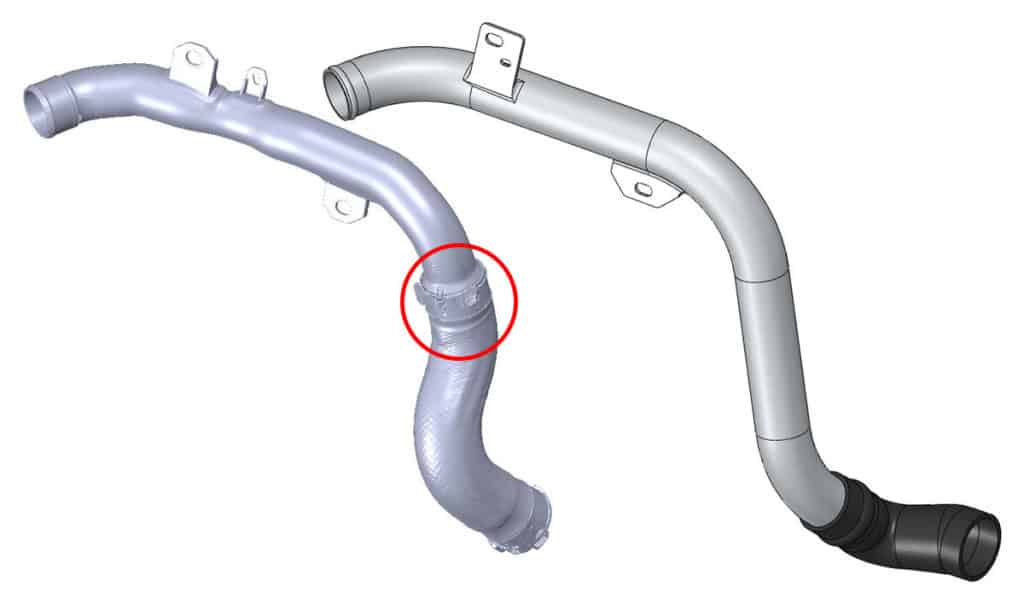

Starting off with the hot side of things (piping from turbo to intercooler), check out the CAD image above. As you can see, the OEM piping (left) is smaller than the CorkSport Mazdsa 6 piping (right). In fact, we plan to use 2.25” piping for the hot side. Note that the plastic OEM piping is much thicker wall than the CS aluminum piping so even if the outer diameter looks similar, the inside diameter is much larger.

In addition, we keep this same inside diameter throughout while the OEM piping has a major diameter reduction through the middle. For those of you coming from a Mazdaspeed 3, 2.25” is the same size used on the hot side of all CS intercooler kits and has proven itself to support 600+WHP on Barett’s car (more info on that HERE). While we know the Sky-T may

It’s not all about size though. Instead of using many tight radius direction changes like OEM, the CorkSport hot pipe uses smooth, large-radius mandrel bends throughout. This means smoother and faster airflow to your intercooler. Lastly, you may notice the CS hot pipe is significantly longer than the OEM hard plastic unit (the OEM rubber tube starts at the connection point circled in the image above). This reduces the amount of flexible connectors used, limiting what could expand at high boost levels. That being said, the CorkSport kit will use high-strength silicone with four fabric reinforcement layers to prevent any expansion anyways.

The cold side of the system was already a decent diameter from the factory, but as you can see, we went even larger. The rubber OEM cold pipe will be replaced with a 3” diameter aluminum pipe. This large diameter pipe and huge volume of air that comes with it right before the throttle body has proven to help throttle response and reduce boost lag on our GEN2 Mazdaspeed 3 FMIC kit. We hope to get much of the same from the SkyActiv 2.5T. The cold side also uses large radius mandrel bends for smooth and fast airflow.

Lastly, the cold side piping reduces the amount of flexible connectors used. And just like the hot side, each end of the pipe will use 4-ply reinforced silicone to prevent any expansion under high boost levels.

Those of you with a keen eye will have realized that our planned silicone connectors do not use the same connection style as the OEM intercooler. This is for good reason: we believe that the OEM intercooler will run out of cooling capacity before the OEM piping really becomes an issue. So a piping upgrade by itself wouldn’t show too much of a performance advantage.

In addition, we were able to design the piping to be the best it can without using the constraints of the OEM intercooler. So yes, the upcoming CorkSport intercooler upgrade will be required for the CS Mazda 6 piping upgrade to work, but it’s so the CS piping & FMIC combo can be the best it can be for you all!

For those of you that have stuck around this long, check out this tease of a CAD model of the CorkSport FMIC & Piping kit.

And just because we like teasing you, check this early prototype out. Testing to come soon!

Stay tuned for more, as next time we will cover the intercooler itself. Also, let us know your thoughts down below, we love your input!

-Daniel @ CorkSport