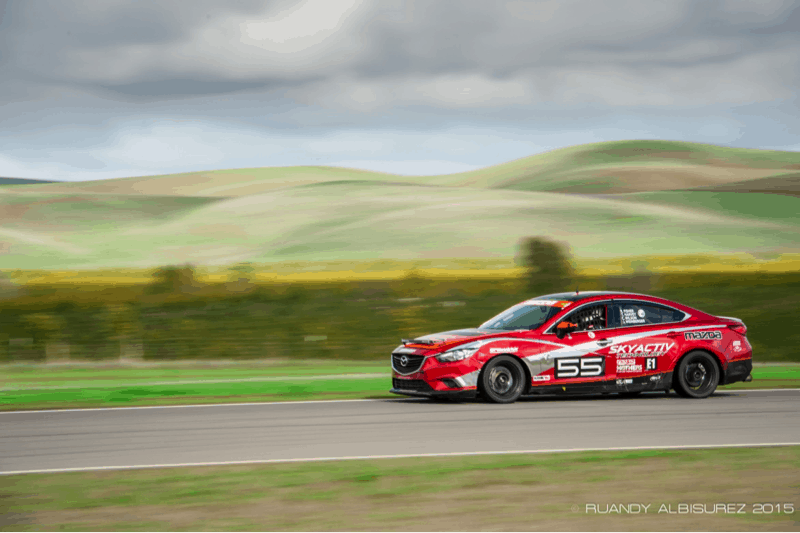

Inside the group of three Mazda Sedans was a rivalry of the Mazdaspeed Guys (comprised of Mazdaspeed Motorsports employees) and the Dealers CEB (Crayon Eating Bastards), a group of Mazda dealership owners/employees. The dealers controlled cars #55 and #56, and the Factory Guys (Mazda Employees) had #70, all fighting it out for bragging rights. Before the race got going #70 hit a snag where a coolant line came loose and overheated a motor, which prompted a Thursday motor change.

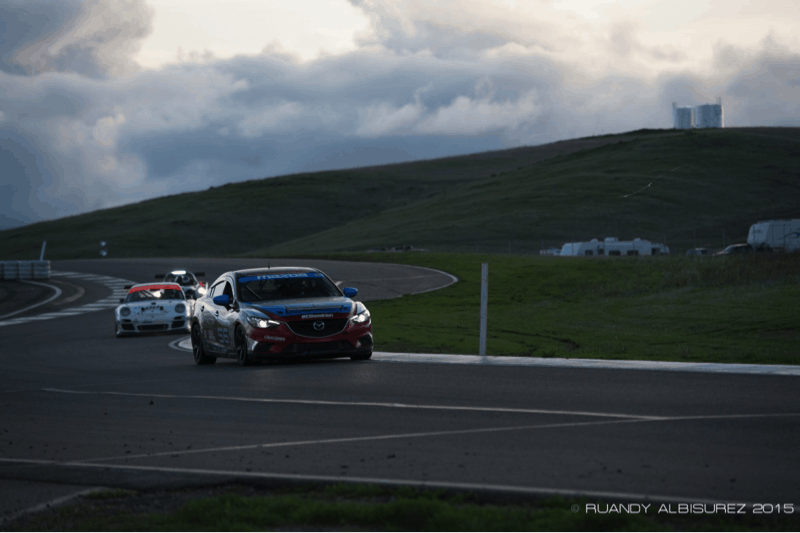

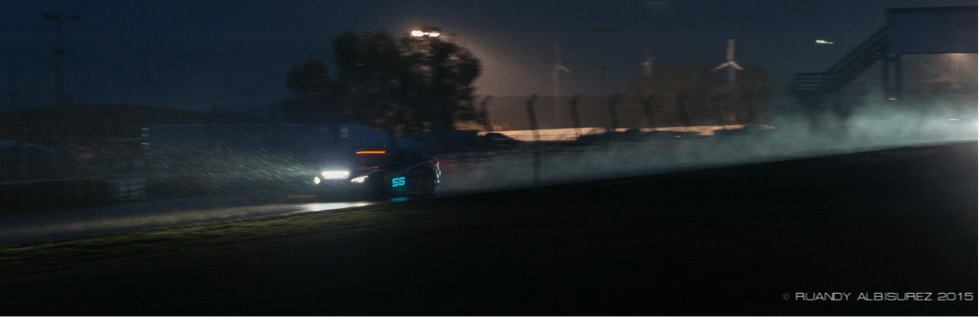

By Friday the cars were all in good shape for qualifying. This went down trouble-free despite a giant rainstorm, as if it wasn’t hard enough trying to run a fast lap with 58 other cars out on the track in six classes— all of which had different speeds.

Thankfully, by Saturday morning the weather had cleared up, and the forecast predicted dry racing for the full 25 hours. This prompted us to get the three cars ready to run on slicks which were mounted up on the wheels and installed on the cars.

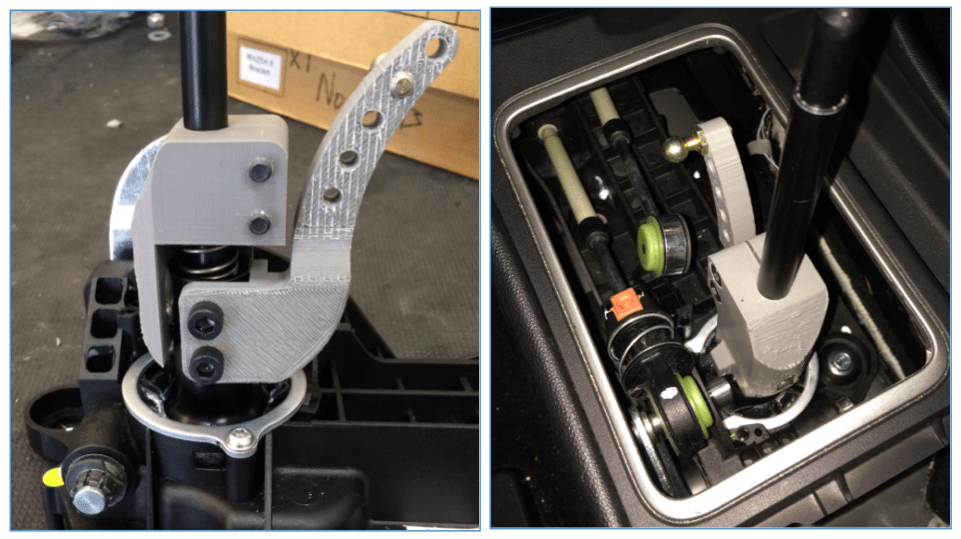

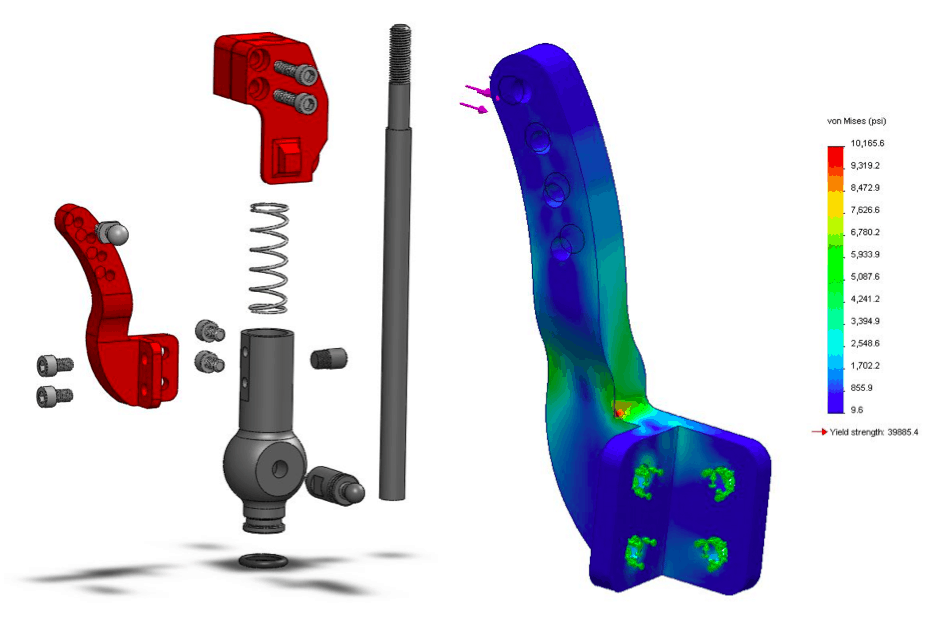

Right at 11 am the flag dropped and started the longest race in North America. This was, needless to say, an adventure for the whole team. Several hours into the race, the driver of #70 reported that the car would not shift into all of the gears. It turns out the extra power was a little harder on the drive train in the higher gears, which removed the 5th gear from being functional. The driver decided to stay out and run the race in 6th gear until the fuel stop came up. That turned out to be hours later courtesy of the excellent fuel economy of the Skyactiv engine. The pit area was prepped for a transmission swap with a spare gearbox the team had brought with them. Unfortunately, this took the car out of any chance of being on the podium, but with endurance racing you never know what will happen! So the transmission change went ahead as planned.

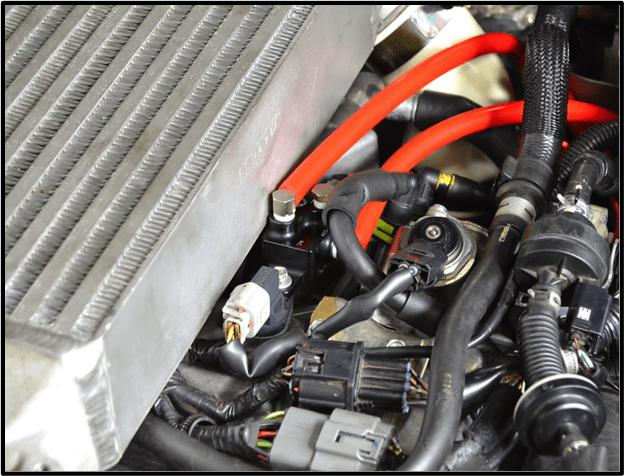

At the first extended yellow flag session #55 and #56 reported a power loss in the cars. This resulted in a massive jam session to diagnose and fix what was going on with the cars. Since these specific cars live their lives on the track they did not get a chance to be tested with the new modifications at low speeds (AKA street driving speeds) which brought up an exciting challenge with the fire control systems in the cars. It took ~about 2 hours to sort out the problem, and we had the #55 and #56 back at full speed heading into the night.

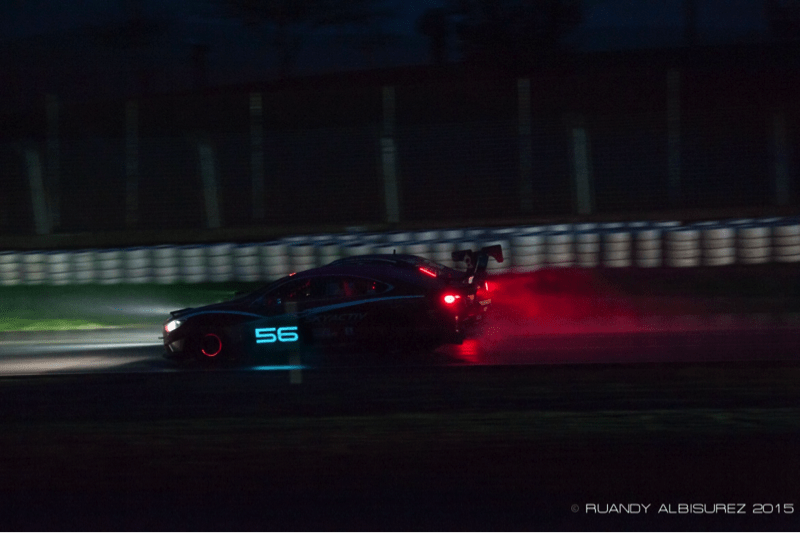

The #70 was getting its final work completed with the transmission change and ready to head out onto the track again well behind the Mazda dealers in the #55 and #56 cars. Late into the night, after a driver change, we got a call in on the radio #55 had an on-track incident with another car in the E2 class, and sadly both cars had to retire from the race. This E2 class car happened to be leading the class which RDR was also fielding “Kermit,” the green RX8, in. Though the incident was unfortunate, as a result Kermit moved to the leader position of the E2 class.

Several hours later we got a call in from #56 of an off-track situation which required the car to retire from the race too. This put the #70 Mazda 6 in position to finish ahead of the #55 and #56 for total laps if its drivers could finish the race trouble-free. As the sun came up, the #70 car was running without a hitch, as was Kermit.

From sunrise until noon, the race for the two remaining cars was uneventful. At the noon finale of the race Kermit secured the win in E2 for the first time! Like in any race, there were things you learn and adjustments for the next time on the track. I want to give a huge thanks to RDR, Mazda, Mazdaspeed, the volunteer crew peeps , and Weldon for the guidance on my first time being a crew chief for an endurance race. Lastly, a big thanks to Ruandy from Pacific Northwest Life for the great camera shots—and to my family for letting me miss an entire weekend at another race.

-Derrick

Interested in any of the diesel performance parts we developed? Shoot an email to sales@corksport.com for more information.