How To Create The Best Pump on the Market

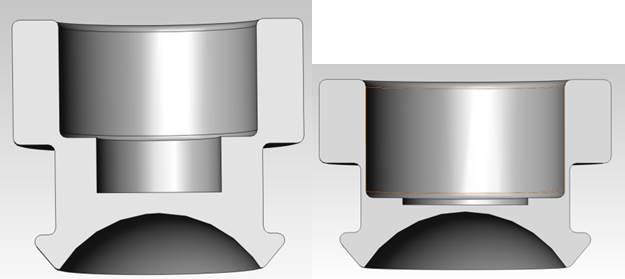

With our fuel pump design complete (link to fuel pump blogs 1,2,3,4), we now turned our attention to the details. We wanted a coating to protect the piston and decrease friction during operation. After testing dozens of compounds, we settled on a very strong coating that is applied with a proprietary process. This process allows for an exceptional bond with the metal, lower static friction, and increases the surface hardness. Before applying the coating however, we wanted to make sure we had the best part possible underneath it. Imagine having an orange that is covered in titanium. The surface might be incredibly hard, but with no substance to back that up you will eventually lose the shape.

After choosing a very strong alloy for our internals, we then machine their tolerances to an incredible 6 microns! To make sure the tolerances are paired for life, we serialize the parts to prevent any issues and to track the life of the pumps. We then surface treat the pumps to achieve the alloys maximum strength; only after the maximum hardness is achieved do we apply our surface treatments to bring the overall durability to an even higher level.

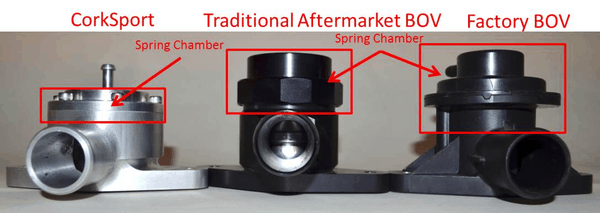

Many companies would be finished at this point but, at CorkSport, our research has shown us that when a coating is applied it is very difficult to maintain a smooth surface. In fact, we found that the coating has many microscopic hills and valleys. There would be no reason for us to go through all the work of having incredible tolerances if we were just going to ruin them with an uneven coating. In order to correct this, the pistons are then re-machined back to their original single micron tolerance. The CorkSport Fuel Pump Internals are the lightest aftermarket kit on the market for faster response and decreased cam wear. At this point it may seem like we are flying this pump to Mars but we just wanted to make the best part on the market, and it worked.

Pump More Than Any Other Kit Available

All of this adds up to an improved pumping volume that is over 8% higher than all other pumps we tested and 50% larger capacity than the stock pump. When other pumps are losing efficiency because of their design or tolerances, ours is just hitting its stride. That difference in the real world is going to be higher HP numbers, safer air/fuel ratios and the ability to go that much further without worrying about your fuel supply.

Because of the increase in fuel we highly recommend that you get a new tune for your car we have made a combo deal to save some money here.

How to Buy the Best Fuel Pump Internals

Now that the cat is out of the bag we can let you know a few more things.

Our first batch is very limited and we want to give everyone that has been waiting a fair shot at getting one. We will release these parts for Pre-Order on November 1st. The Pre-Order will be limited to the first 100 paid orders or November 14th, whichever comes first.

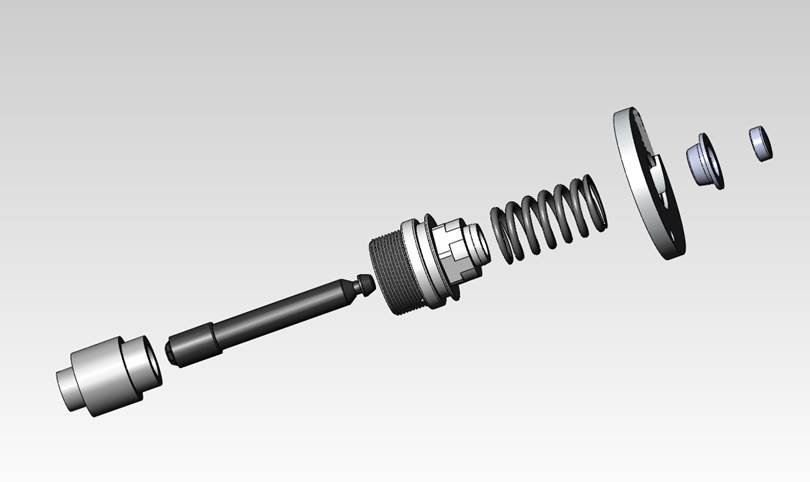

The CorkSport High Pressure Fuel Pump internals include a collectable aluminum box with:

- Full color instructions

- Stainless Steel Installation Tool (That also doubles as a keychain bottle opener!)

- Anodized Aluminum Installation Sleeve

- CorkSport USB drive with Installation Video, Promotional Video and Other Bonus Material

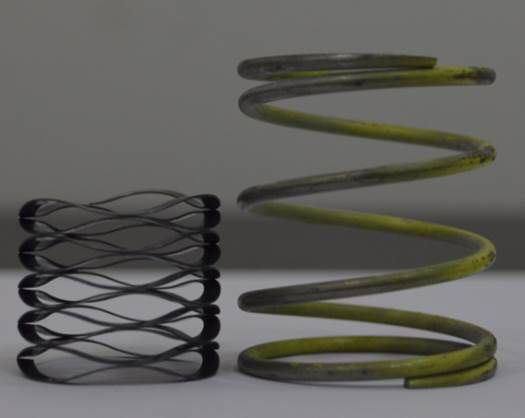

- CorkSport Precision Fuel Pump Internals (including higher rate spring)

- Retaining Hardware

The Pre-Order will go live on November 1st at 12am Pacific Standard Time and will remain up until the initial 100 orders have been placed. Unfortunately these are the only internals we will offer for 2013 so if you miss the pre-order you will have to wait until next year to get the best fuel pump upgrade on the market.