When designing an aftermarket rear swaybar, there are two main concerns, the weight of the bar, and the stiffness of the bar. The design chosen for the bar needs to be strong enough to resist chassis roll, while being light enough to keep weight down.

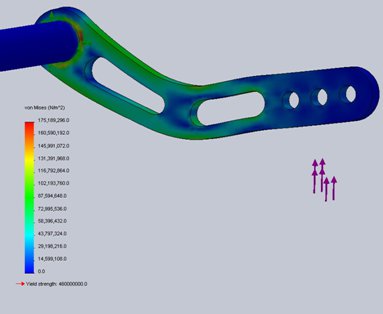

To battle the weight issue, we used a hollow tube for the main shaft of the bar. Hollow tubes are able to provide a greater torque resistance than a solid tube of equal weight. In addition, the two arms that connect the bar to the end links were optimized for weight by using finite element analysis. This allows me to design a bar that is structurally rigid, while removing material from areas of low stress. The image below simulates a load coming from the end link of the vehicle and the stresses that it puts on the arm. The deflection is exaggerated to give an idea of how the bar flexes during cornering.

The increased stiffness of the bar comes from increasing the diameter of the tube. To allow this, we utilized a set of larger diameter urethane bushings with greasable fittings. This allows for a more rigid mount, while giving you the option of greasing the bar without having to remove the bushings. The whole system is topped off by having 3 adjustable mount points of varying stiffness from 20% to 80% stiffer, while offering roughly 3 pounds of weight savings. The bar is powdercoated to protect it from the elements and keep it looking nice.

– Jake

Awesome design and adjustability. Can’t wait to get it.

Since your using a hollow bar are the ends open? It kinda looks that way from they CAD image. Also the the ID of the tube?

Are the ‘endlinks’ welded to the torsion tube or are they a press fit internal/external spline? Splines would allow different tubs to be used for varying stiffness (if spline diameter is same as maximum possible bar OD) Just a random thought that would make it work well with a road-racing application

We had discussed this during the development cycle, but decided that it would create unwarranted complexity for most customers. The tube is welded to the ‘endlinks’.

It looks like the factor of safety against yield is 2.7. What is the FOS against fatigue failure? Do you do a similar run for the mounting points on the frame or the endlinks. What were the FOS’s for those?

Have had knocking issues. Ordered new bushings, hope this will solve the knocking. had CS send me the collars that should have been sent to me. This did not remove all the knocking. Will see when new bushings are installed. If not will change style to newer Mazdaspeed rear sway bar.