We love to hear some of the ideas our customers have when it comes to product development. You have some great ideas that have been shared with us in the last few months.

In keeping with our goal of providing excellent customer service and technical support to our customers, we would love to hear some of the tips and tricks that you use when doing installations, modifications or routine maintenance of your Mazda. Could be great ways to keep the oil from spilling all over the rotor housings on your RX-7 during an oil change (that upside down filter is a gem, isn’t it!), solutions to removing or reinstalling the downpipe on the MS3 (those studs don’t like to stay put in the turbo, do they!), or even something as simple as methods on how to keep your tools organized or functioning to their fullest.

In return, we’ll give a 10% discount code (not to exceed $25) for use toward any CorkSport Brand Parts to the top three tips submitted in the next three months.

Feel free to submit video, photos or diagrams to support your ideas.* The clearer you make the content, the better your chances are of getting the discount. We’ll publish the best tips here in our blog and give credit to everyone who submitted ideas. Submit your content to: wr********@*******rt.com.

For Example:

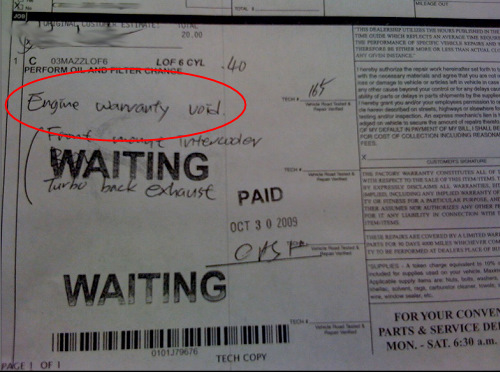

Here’s an tip I learned from an Aircraft & Powerplant mechanic who spent countless hours slogging through the muck repairing Aircrane Helicopters that had broken down in the field (or more appropriately out in the middle of nowhere in the woods). This trick was so helpful that he kept a can of Bon Ami sink cleaner in his toolbox. Aircraft and automobile engineers love to use phillips drive screws to hold all sorts of things together. And whether we ourselves have ham-fisted an install and thrashed the phillips drive in the top of a screw or it was the fault of the DPO (Dip-$&*%Previous Owner) , the solution is often times to get out the dremel and make it worse before it gets any better.

Alas, there is a solution that works perfectly, especially in those applications where the Phillips drive is HUGE and holds something on with substantial amounts of torque and your ‘bash it with a hammer’ impact screwdriver has eaten the top of the screw for breakfast.

So before you put all your weight into your battery powered screwdriver and turn what still looks remotely like a usable screw into a finely machined cone…take a deep breath. Go into the kitchen or (if you’re a bachelor and don’t know what this room in your house is for other than storing giant garbage bags of empty natty light cans) grocery store and pick up a can of abrasive sink cleaner like Bon Ami or another abrasive polishing powder. Mix it up into a paste and dip the end of your screwdriver into it. The paste is aggressive and will grab uneven surfaces of the drive in the screw and it will come right out. Make sure to continue to use plenty of downward pressure as well so the driver doesn’t just jump out of the contour of the screw. This trick also works well on partially rounded off hex drive fasteners like those M8 head exhaust manifold heat shield bolts on the MS3/MS6/CX-7.

Just don’t let your wife know that you’ve been stealing things out of the kitchen for use in the shop.

They don’t like that.

– Jason

*All content submitted will become the property of CorkSport.