Many months ago here at CorkSport we decided it was time to bring a new high performance BPV to the market. The goal was to design a BPV that was compact, durable, and performed beyond just making noise; most importantly this BPV had to feature VTA functionality that was a right balance of daily driver friendly and performance. Ladies and Gentlemen, boys and girls, I give you the new CorkSport VTA BPV.

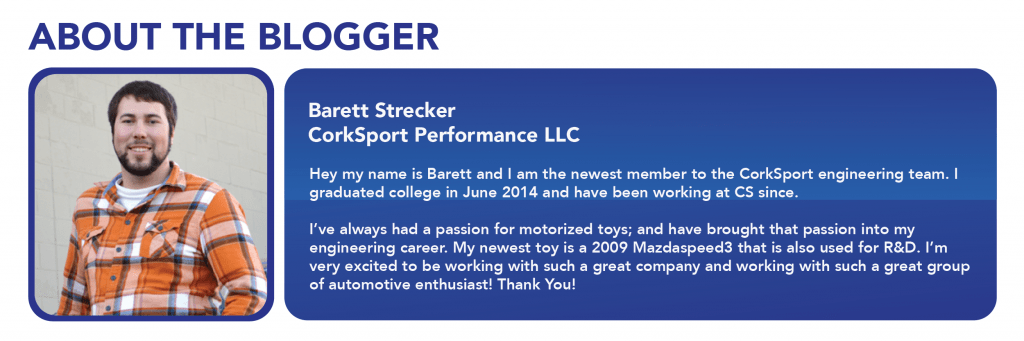

A beautiful picture of the outside looks nice, but does not even begin to show the many features designed into this BPV. Let’s take a look inside.

Looking at the first cutaway view shown in Figure 1, you’ll immediately notice the three O-rings. Two are located on the sides of the piston and one is located at the bottom of the piston. These are important for a couple reasons: the O-rings allow the piston to actuate/slide easily when combined with a proper lubricant and provide air tight seals in all piston positions. This allows the valve to hold 50psi of pressure without leaking.

I specifically identified the VTA port because it location is critical to the BPV design and the drivability of the vehicle. In the idle position the piston sits at approximately the same position as shown above due to the vacuum pressure sourced from the intake manifold. At idle the VTA ports are closed, keeping your fuel trims in check.

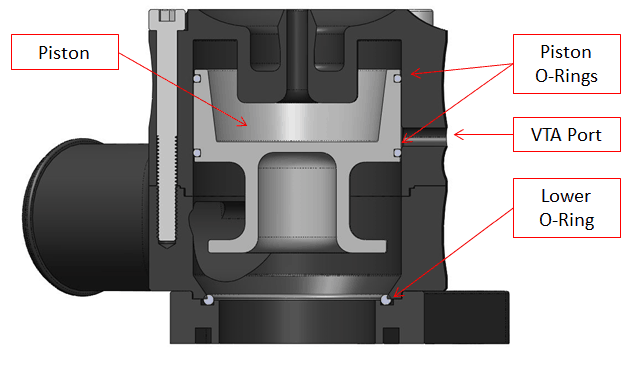

Next, let’s look at the BPV in positive pressure (building boost) situation.

Immediately after applying throttle, the intake manifold begins to increase in pressure due to the turbocharger building boost. At the same time the BPV piston is forced closed as shown in Figure 2. Like the idle position, the VTA ports are closed keeping fuel trims in check. The piston also creates an airtight seal against the base flange improving boost response.

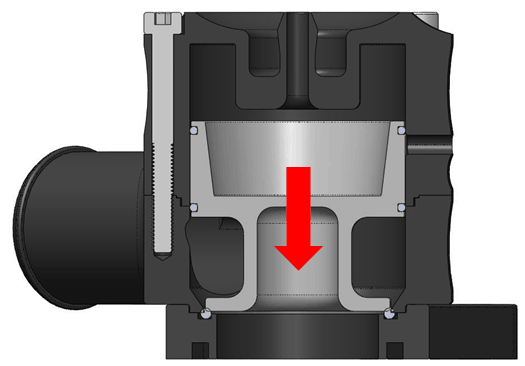

Next you shift or get off the throttle which causes a sudden pressure change in the intake manifold and the charge pipe pre-throttle body. The excessive pressure build up in the charge pipe combined with the vacuum from the intake manifold cause the piston to open as shown in Figure 3 below.

Unlike the idle position, the piston has moved up past the VTA ports. This is due to the excessive pressure differential between the piston vacuum chamber and the charge pipe pressure. The greater this pressure differential the faster the piston will respond and vent more air to the VTA ports. Testing has shown that the VTA ports begin activating at ~15psi or greater boost pressures on a K04 Turbo equipped Mazdaspeed.

So that’s how the CorkSport VTA BPV works, but what makes it so efficient in doing so? A combination of simple and effective features all wrapped up into one design.

Response is key to a great performing BPV, plain and simple. The piston inside the BPV must respond and accelerate extremely fast in order to reduce the pressure in the charge pipe and protect the turbocharger. Attaining that response comes down to simple physics in the form of Force = Mass * Acceleration. We can directly affect the mass of the piston via design and materials, which we were able to get down to a mere 38 grams w/O-rings. We can semi-directly affect the force required to accelerate the piston which various spring rates. Therefore by reducing the weight of the piston and optimizing the force applied to the piston we were able obtain a remarkable response time.

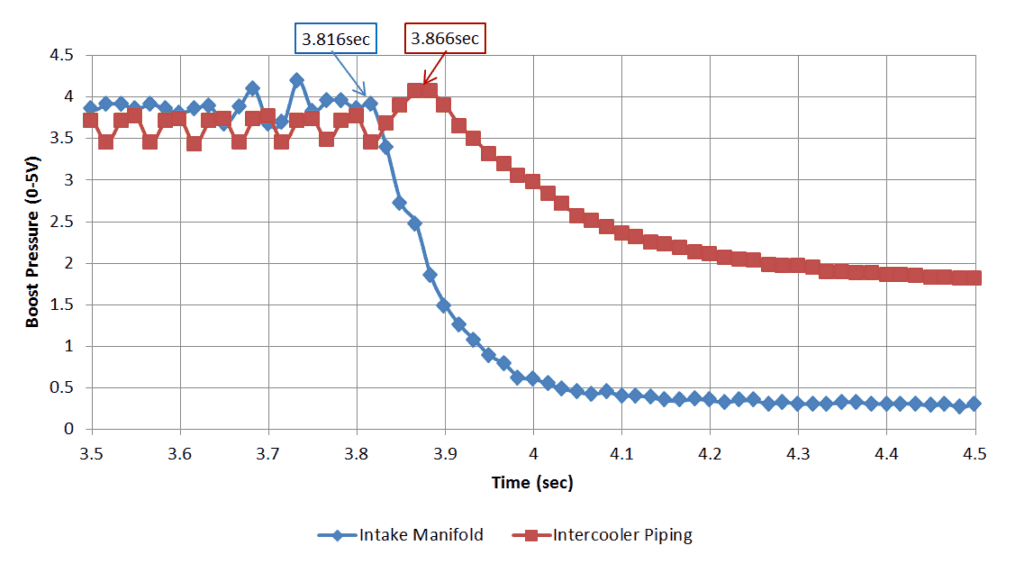

Looking at Figure 4, you can see two separate graphs shown. The blue graph shows the intake manifold pressure in a 0-5volt range. Boost pressure was leveling at ~23.5psi on a CorkSport turbo equipped vehicle. The red graph shows the charge pipe pressure just ahead of the throttle body approximately where the BPV is located.

During the test the car is held steady at ~6000rpm so that boost can level off for ~5sec, then the throttle is abruptly closed; this is shown in the blue graph with the sudden decay. This causes sudden vacuum in the intake manifold and increased pressure in the charge pipe pre-throttle body. The pressure delta causes the BPV piston to react and vent which is shown with the slight increase and then decay of the red graph. The response time of the BPV is time delta from the intake manifold going into vacuum and the BPV beginning to open and vent. The resulting time delta is a remarkable 50 milli-sec or 0.050sec in general terms.

The piston isn’t the only optimized part of the BPV. The piston design and the BPV cap were designed to work together. Looking at Figure 3 you can see that the hose barb fitting is integrated into the cap design and more importantly is “inside” the piston as much as possible. By reducing the volume of the vacuum/boost signal chamber in the BPV, we have reduced the total volume that must be removed from the chamber before full vacuum occurs and can begin moving the piston. You could compare this to “shot-gunning” a can of beer. The tall boy is going to take longer than your standard 12oz right? Same idea with the BPV, but we are trying to shave milli-seconds.

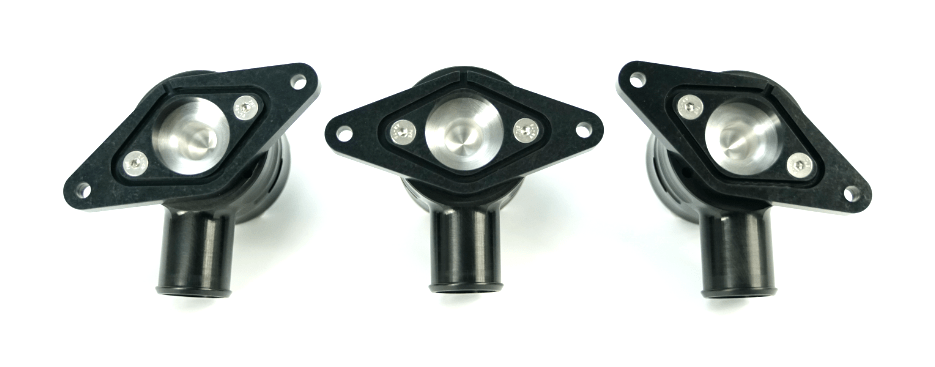

Another awesome feature on the CorkSport VTA BPV comes in the form of installation flexibility. Not only is the BPV compact at just 2.50 inches tall, but the flange can be adjusted to a total of five positions. The center BPV in Figure 5 shows the typical position for a Mazdaspeed BPV. From there the flange can be adjusted 15 or 30 degrees clockwise or counter-clockwise to aid in installation.

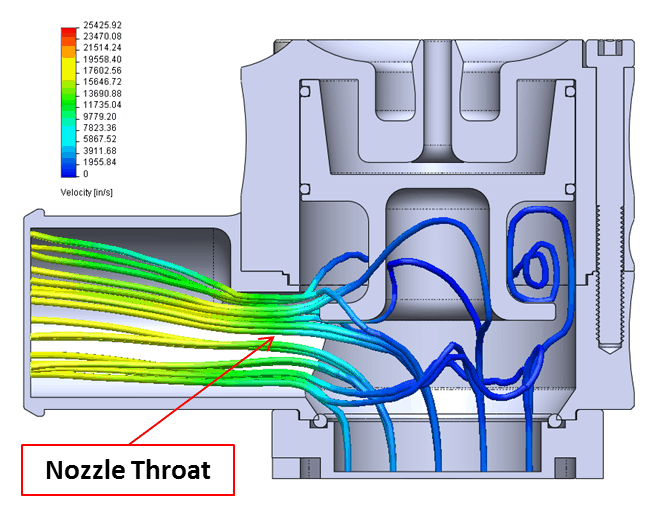

Lastly, and arguably most important, the CorkSport VTA BPV flows great. Figure 6 shows a CAD flow simulation of the BPV fully open with inlet condition 23psia @ 110F and outlet condition 7 inches of H2O vacuum. Mach flow or commonly called “choke flow” is the situation when the air velocity reaches Mach 1. At this point no more airflow can be pulled through the BPV without increasing the pressure at the BPV inlet (charge pipe). In the CorkSport VTA BPV, Mach flows begins to occur at the nozzle throat shown in Figure 6. This is to be expected with the compact design and was a compromise made in the design process; however you will notice that the CAD simulation does not take into account the potential flow of the five VTA ports. These will only increase the maximum potential flow of the BPV.

To top it all off, the CorkSport VTA BPV makes an array of noises ranging from subtle whistles to loud whooshes. I invite you to check out the video found in the product listing as words just cannot give it justice.

We set out to design a high performing VTA BPV for the Mazdaspeed community that delivered with performance, style, and entertainment. We believe we delivered with a leak-proof, fast responding and glorious sound BPV. We hope you enjoy your new CorkSport VTA BPV as much as we enjoyed designing it.

-Barett