When you look at the blow off valves (BOV) and bypass valves (BPV) on the market today you see many examples of the same thing with little to no innovations. For those of you that aren’t aware, BOV’s and BPV’s are valves that vent pressurized air in the tract between the turbo and the throttle body. This prevents the turbo from suddenly stopping or slowing as those can cause unwanted bearing wear on the turbo. A BOV vents this pressurized air into the atmosphere (into the engine bay). A BPV vents that air back into the intake just after the mass air flow (MAF) sensor. Venting back into the intake allows the ECU to correctly meter that air that it has already accounted for. Many times when venting to atmosphere you can get a momentarily rich condition because the ratios are off.

We were talking about innovation though, the last great innovation in valve technology for turbos was probably years ago with pull type valves like the SSQV from HKS. Many years have passed since then and not much has changed, outside of the few valves that partially vent to atmosphere and route the rest back to the intake tract. Typically now you just see one copy after another of someone else’s idea. SURE, it can be hard to innovate in the blow off valve market but we were convinced there was something exciting we could do.

We speak often about your ideas sparking our innovative minds, this project was started by just one of those customer suggestions. We started with a customer submission of using wave springs that led us to design a new valve design to reduce the size and weight of the moving parts.

Key Features of the upcoming patent pending CorkSport Blow Off Valve:

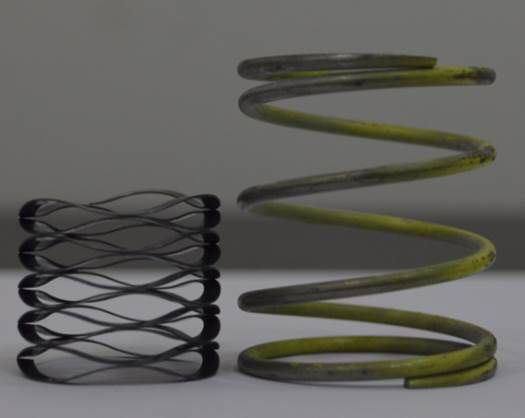

With the use of a wave spring we are able to reduce the spring height by 50%. The traditional spring sits at 40mm and the CS wave spring sits at a 20mm height. These springs both provide the same force and will move the same distance before experiencing coil-bind.

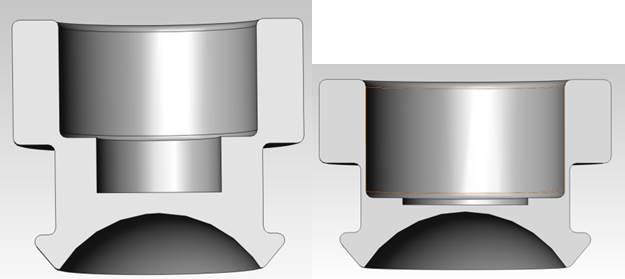

Reduction of piston size

Because the spring is 50% smaller we are able to reduce the piston and still maintain the same amount of movement. As you can see, just changing to the wave spring we were able to decrease the piston by 33%!!!

What does that all mean?

The reduction in mass is all well and good, but just being smaller isn’t the only benefit (even though that is pretty cool). With the force (F) being the same and the mass (m) decreasing by 33% we can see how the mass relates to acceleration (a) in the formula F=ma. Rearranged, this becomes a=F/m. This means we have accelerated the actual speed of the valve, which means the valve is able to react much faster than a larger valve with a traditional spring (33% faster!) Because the blow off valve is a safety feature to protect the turbo from premature wear, this increase in acceleration can help increase the longevity of the turbo and the system as a whole.

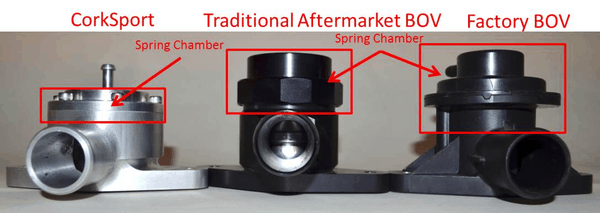

What does all this innovation look like?

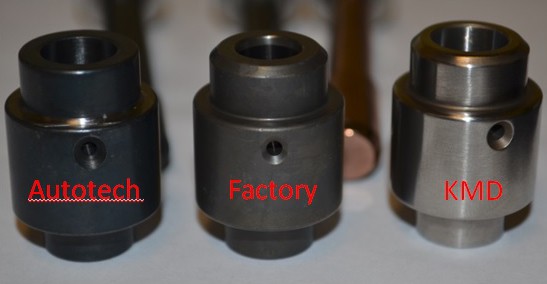

With the reduction in the size of these key parts, we can reduce the body size. This can be especially helpful in situations with airboxes, custom turbo and intercooler kits or even in universal situations where space is at a premium. Below you can see a comparison of similar BOV’s, the spring chamber on our design is significantly smaller but the function is not lost; in fact, we improved it!

To maximize flow, we pushed the piston area out to ensure a larger venting area, this reduces the time it takes to vent the air and allows larger turbos to vent more efficiently. As a blow off valve, this certainly pushes the envelope, we think we can find even more applications for this kind of innovation. We are very proud to be able to offer things for the Mazda market we helped create and will continue to engineer parts that push the scene for you.