Let me take you to an extraordinarily dull time in my life, the last time I started my Mazdaspeed when it was still stock.

September 14th, 2018 was a beautiful September day in Washington. I started my car at 6:45 am, just like every other weekday. The Speed3 burbled to life, but it was relatively quiet, flat, and a bit uninteresting. No one knew I was leaving for work – I wasn’t shaking any windows, but that was going to change.

Once I arrived at work and spread some Friday cheer, I settled in. Almost immediately, I could feel the pile of parts in the corner behind my desk, glaring at the back of my head. I thought to myself, “Don’t turn around – focus damn it!” The day had finally come – install day. Thankfully with our awesome half-day Fridays, I was out of the office and on my way to Brett’s house before 12:30 pm.

After we loaded up Brett’s Rodeo with a load of parts, we set sail to our destination, a place where many tears have been shed, knuckles have been busted, and where dreams have come true; Brett’s garage. Every tool you’ve ever needed and gadgets you didn’t know existed. There were even a few specialty items present, that if he didn’t have quite frankly, this couldn’t have happened.

We started with thorough degreasing of the engine bay and setting up the essential supplies- because what is an install day without beer and snacks! Once the car has cooled down, I started with taking out the battery box, intake, and intercooler; and then the fun really started. I’ve read the horror stories, I’ve watched the videos, and I thought I spent enough time mentally preparing myself for what was about to come – I was wrong.

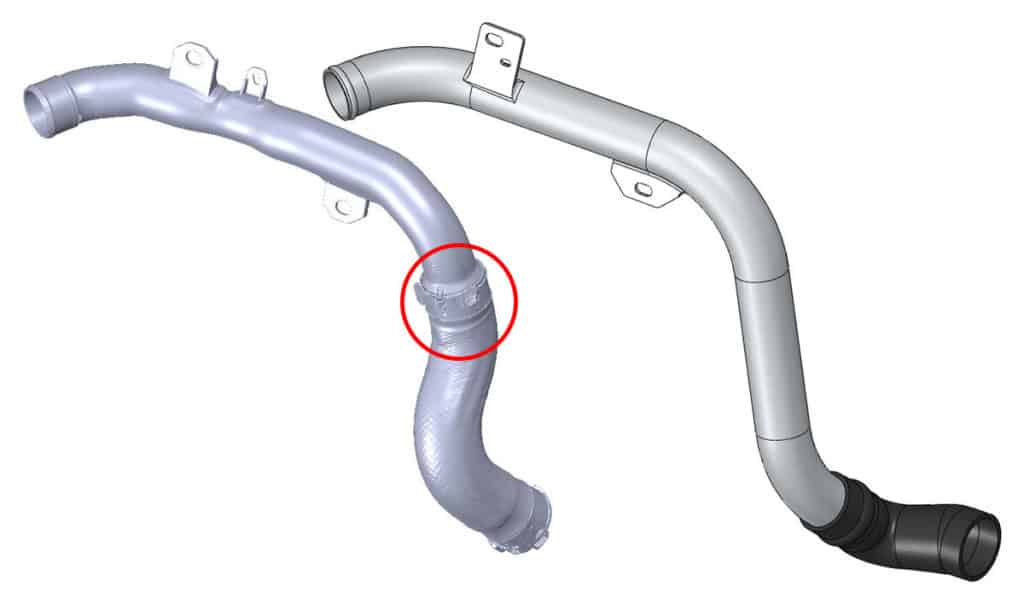

The Downpipe

We all know about the Mazdaspeed downpipe on our cars. The devil engineered the placement of this thing, and he had his minions tighten the bolts. There isn’t enough PB blaster in the world to help the corrosion and excessive heat that these bolts withstand. We got the first one out with little to no issue, but it just got progressively harder from there. It was only a matter of time before rounding off the edges of that last bolt. Thankfully Brett has an extractor tool that we hammered on there, and with the small act of god, it was successfully extracted.

My experience with removing the downpipe from the exhaust, as is everyone’s experience, was different. Mine was influenced by the previous owner adding a 2.5″ resonated exhaust on it from the second cat back. The downpipe didn’t want to come out until I wiggled a pry bar in between the flange and put Brett’s Caliper spreader in there (again tools I didn’t even know I needed) and applied sheer grunt force. I got the flange to bend, and after learning a few new choice words, we got it out. By this time, it was 11:30 pm, and we still had a few other things to unbolt before the exhaust came out. Instead of using power tools and waking every neighbor up in a two-block radius, we called it a night.

The Morning After

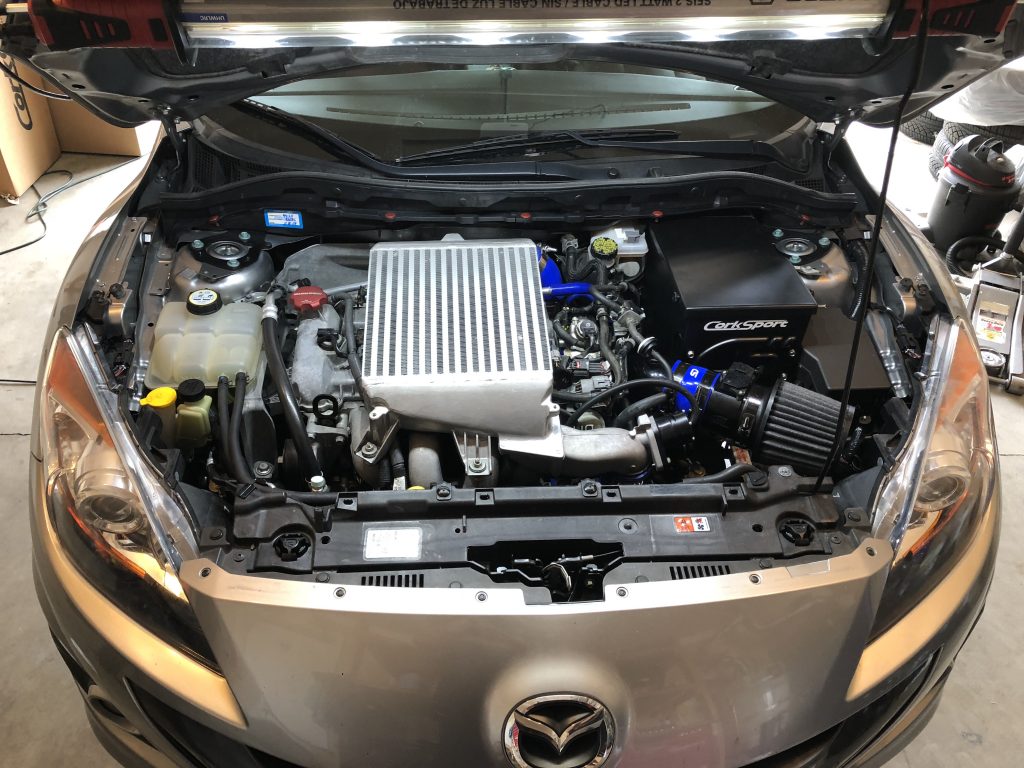

After some much-needed coffee, we made it back from the hardware store (replaced the downpipe nut from hell) it’s time to party. We started with sliding in my new downpipe with the High flow Cat what a breeze compared to taking it out. Next came my intake, I went with the 3.5″ so I don’t have to buy another one when I finally go with our CorkSport CST4 turbo. Still might go with the new CST5. Then I put in my ECU Relocation Box, and I have to say, what a clean looking piece to have in your engine bay!

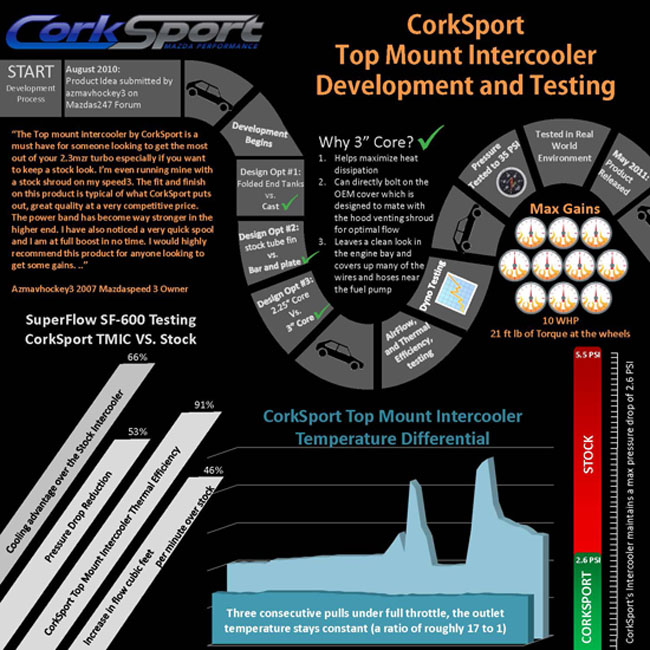

We changed out the OEM spark plugs for some NGK 6510 gapped to .026 and started to put on my new TMIC that is rated up to 450WHP after we got the TMIC it was time to put on my shiny new boost tubes Engine bay= Complete.

Now time to get underneath and put on my highly anticipated Non-Resonated Cat-Back exhaust and my Stage II RMM. Goodbye, torque steer! Once we had the exhaust mostly in place, I realized if I didn’t have the CS exhaust hangers I would have been in trouble. The person before me had his exhaust welded quite poorly in place of the hangers, and I didn’t have an option to use my OEM ones.

Moment of Truth

After everything was double-checked and rechecked, it was time for the moment of truth. I hooked up my battery, I flashed my new tune from Erik Bjork at Drama Tune, and now it was Go Time! I will say hearing my car make those sweet sounds was one of the best moments of my life. I’ve been waiting for this moment since I purchased my car, and it was one of the most surreal experiences I have ever had.

We let the car run for a few minutes and checked to make sure I didn’t have any leaks, and then we headed out for a test drive.

In the immortal words of George Takei “Oh My!”

That was my thought, EVEN on just a base map. My car felt and sounded 1000% different than before. The intake was amplifying fun new mechanical noises – like I was hearing my turbo and BOV dance for the first time. The crackle from the exhaust on a hard 2nd to 3rd upshift was intoxicating, all the while my RMM putting in work to make sure I didn’t torque steer into someone’s front lawn. What an experience! I would even call this life-changing for me. The funny part of the story is that I wasn’t planning on buying all these items at once – true intentions of a foolish car enthusiast. Thankfully for me, I have a fantastic career within CorkSport and have a great friend who helped me make my dreams come true. Who wants a stock car when you work for the number one place in the world for Mazda Performance, not this guy?

Keep an eye out for my turbo blog, because it’s only a matter of time until the mod bug bites me again.

Connect with us

You may also like

- How To Achieve 400 WHP In Your Mazdaspeed

- CorkSport’s Best Mazdaspeed Coilover Kit Just Got Better

- Best Mazdaspeed Turbo Upgrades – Choose Your Boost

- How to Get A 900 Horsepower Mazdaspeed 3 AWD Swap – The Intro