Things don’t always go as planned. We begin a project thinking our customers will be able to get good results out of a new performance product only to find, when we start testing, those results don’t show up.

An example of this is the CorkSport Cold Pipe. After investing months in the development process, we are choosing to abandon the product and put our development efforts elsewhere. Focus on products that will provide our customers with the type of performance benefits that inevitably did not show up during the testing of this product.

How it all began:

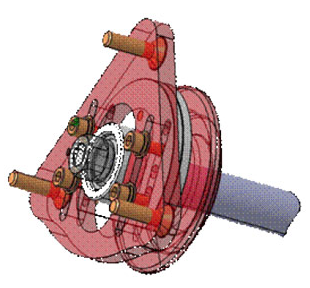

After seeing the great success of our Top Mount Intercooler and the amazing benefits it offered, we wanted to find a way to give customers who chose to stick to a TMIC even more performance. Looking over the TMIC system we noticed that when the air exits the intercooler it immediately hits a wall. It exits the intercooler towards the front of the car, but just after exiting it is forced to the driver side.

Once we identified this potential air flow restriction, we decided that it would be worth it to try and expand the stock cold-pipe to provide a better path for the air to flow, as well as a larger volume to accommodate the increased flow seen with a CorkSport TMIC.

The development process:

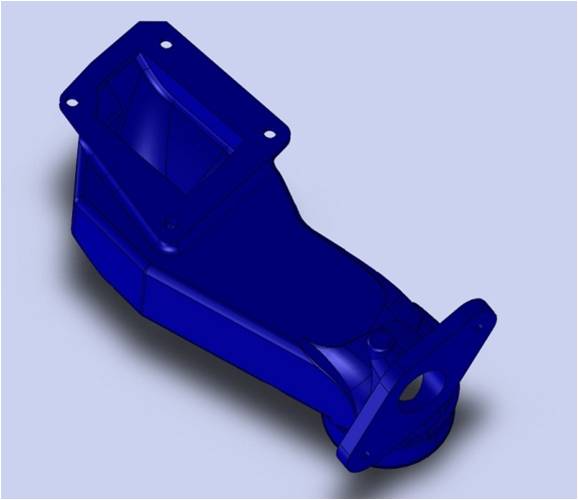

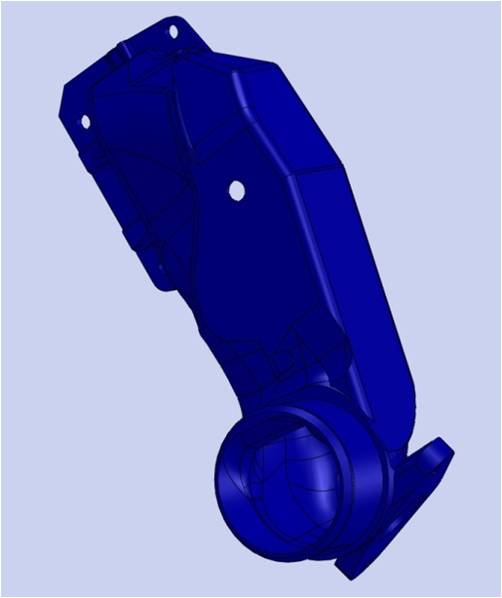

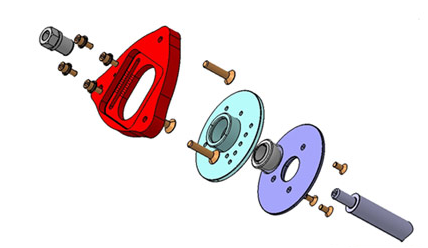

We scanned the stock pipe into a solid model so we could improve flow and still provide a great OEM fit.

Once we had a CAD model, we noticed the access to one of the four TMIC mounting holes became covered so we added an access hole to be able to tighten down this bolt as well as provide a NPT fitting to be used with water/methanol injection.

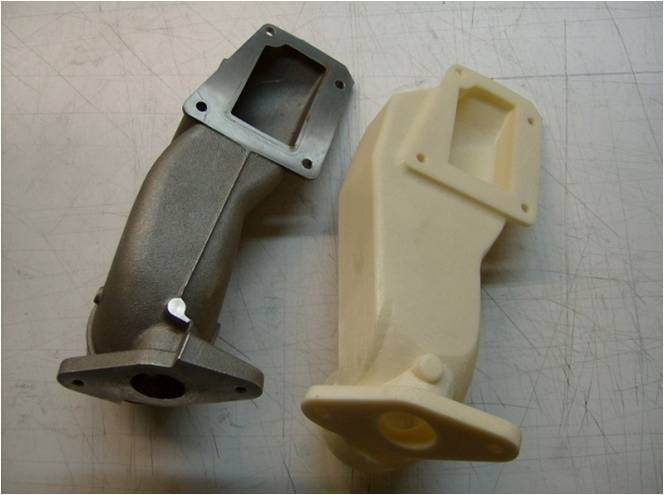

We proceeded with some virtual testing and discovered that the flow was more even and fluid as it moved through the redesigned pipe when compared to the stock pipe. Once we felt good about the revised drawing, we took the CAD model and did a 3D print to check fitment and conduct real world flow testing.

The part fit great and looked great. We were very happy with how the project was turning out, so the next step was to do some flow tests to determine the exact gains that the redesigned part offered.

The outcome:

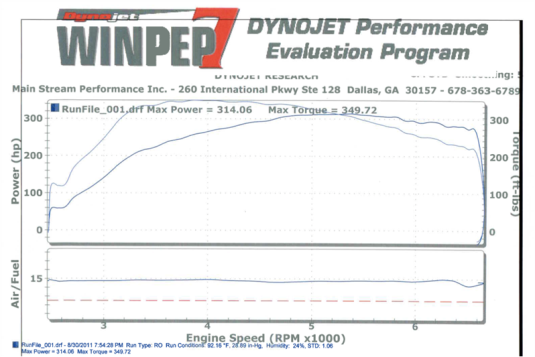

We were disappointed with the results. The redesigned cold-pipe by itself offered a 15% increase in flow over the stock cold-pipe. When combined with a CorkSport TMIC however, both pipes flowed the same. Since the intercooler’s max flow (still significantly higher than the stock TMIC) was less than either of the cold pipes by themselves, the redesigned cold-pipe and CorkSport TMIC only flowed 0.7 CFM more than the stock cold-pipe and CorkSport TMIC, a negligible amount.

Knowing this, we now had a big problem. Why would anyone want to upgrade this part for a negligible performance improvement? Sure the option to do methanol injection would be great for some but we didn’t think most people would be interested, even at our target of $125.

We hit the forums, Mazdaspeed Forums to be exact, and asked what they thought of the product and if they would still be interested in the product with the minimal gains seen. The general consensus was that although it was a great idea and seemed to have a lot of development and engineering behind it, they didn’t feel like it would be worth the cost or that we would see enough sales to warrant producing the part.

With this feedback, we decided to abandon the project and cut our losses on the development time and money we put into the product. Unfortunately this happens occasionally. We work on a project only to end up killing it before we reach production. It’s just the way development goes sometimes, but each and every time we can take it as a learning experience to further our knowledge about what projects may or may not be worth pursuing in the future.

We want you to feel confident that our products do what we say they will do and though it’s not an easy decision to scrap a product after investing thousands of dollars on development, when the alternative is to release a product that has no performance benefit when our customers are expecting one, the choice is simple, abondon ship.

Andrew-

.jpg)

.jpg)

.jpg)